Non-chrome resin composition, method for processing steel plate surface and steel plate

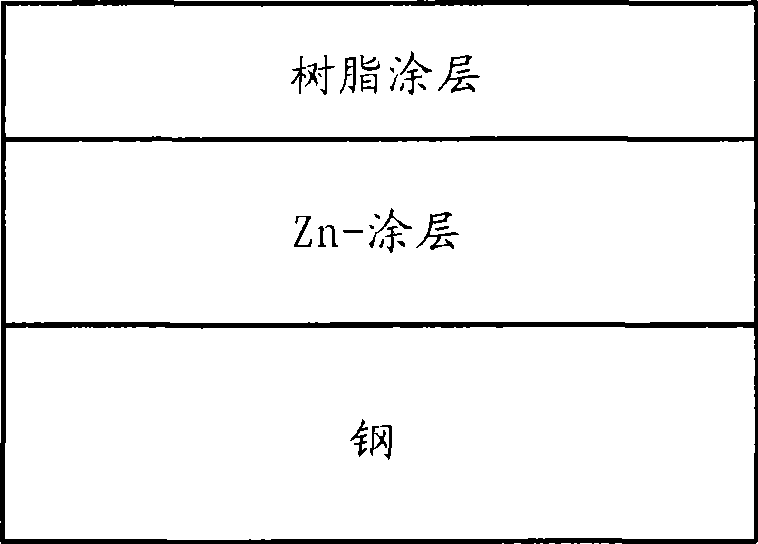

A resin composition and resin technology, applied in coatings, anti-corrosion coatings, metal material coating processes, etc., can solve the problem of metal plate conductivity and welding performance degradation, product surface discoloration, unsuitability for suppressing electromagnetic waves and internal noise, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0073] Hereinafter, the present invention will be described in more detail with reference to exemplary embodiments of the present invention. It should be understood, however, that the description set forth herein is a preferred example for purposes of illustration only, and is not intended to limit the scope of the invention.

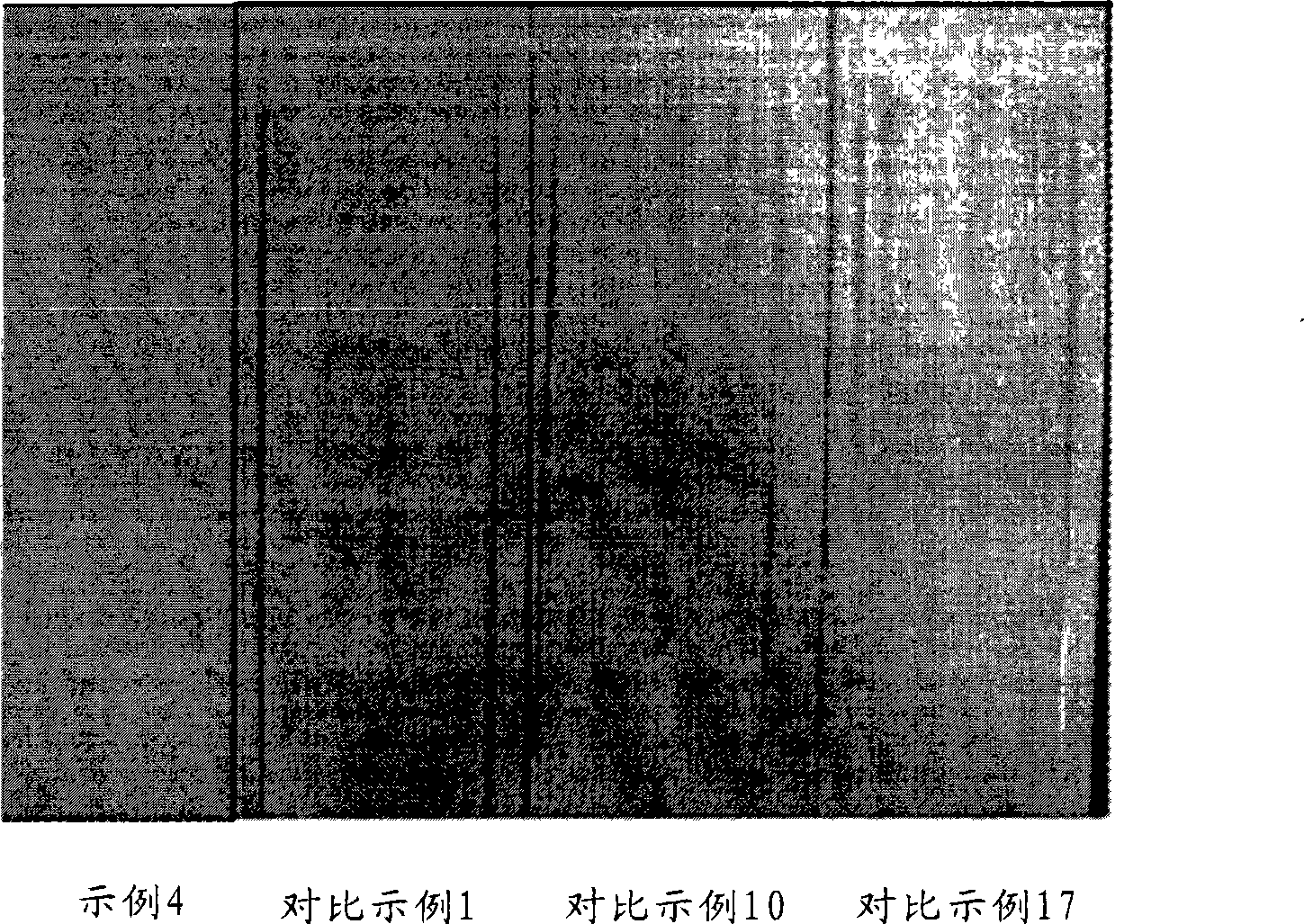

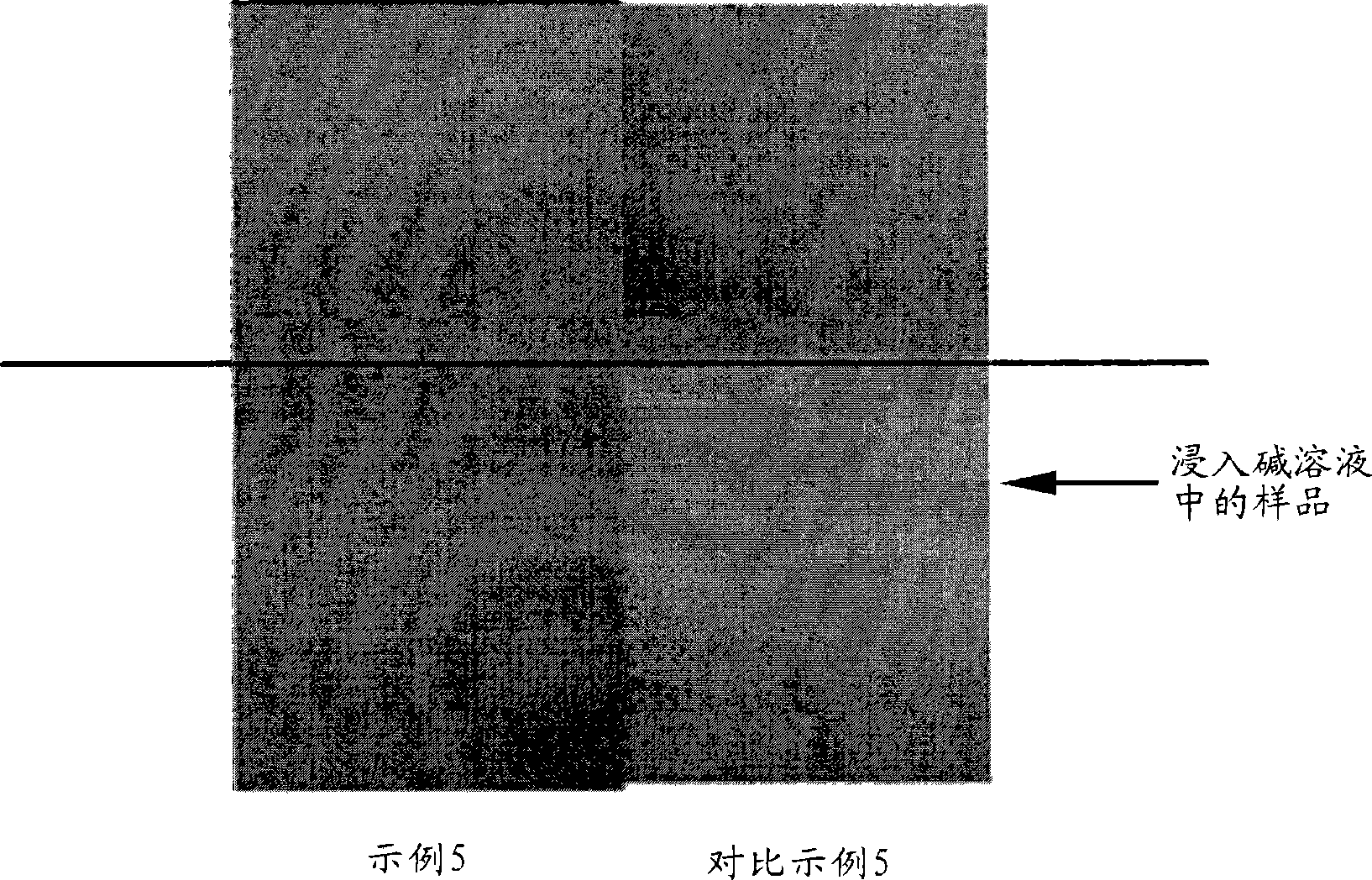

[0074] Example 1 to Example 13 and Comparative Example 1 to Comparative Example 14

[0075] 1-1. Preparation of resin composition

[0076] A urethane resin with a number average molecular weight of 100,000 composed of isoprene diisocyanate, adipic acid and polyol monomers was prepared as a soft urethane resin monomer. In addition, urethane having a number average molecular weight of 1,000,000 was prepared as a hard urethane resin monomer from p-phenylene diisocyanate and polycarbonate polyol monomers. Ti organic oxide (Tyzor TE) of Dupont company available on the market Triethanolamine isopropyl titanate) was used as a corrosion-resistant curing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com