Detonation velocity photoelectric test method and apparatus of detonating cord

A photoelectric testing and detonating cord technology, applied in the field of mechatronics, can solve the problems of large volume, complex structure, low reliability, etc., and achieve the effects of strong anti-interference ability, broad application prospects and high testing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

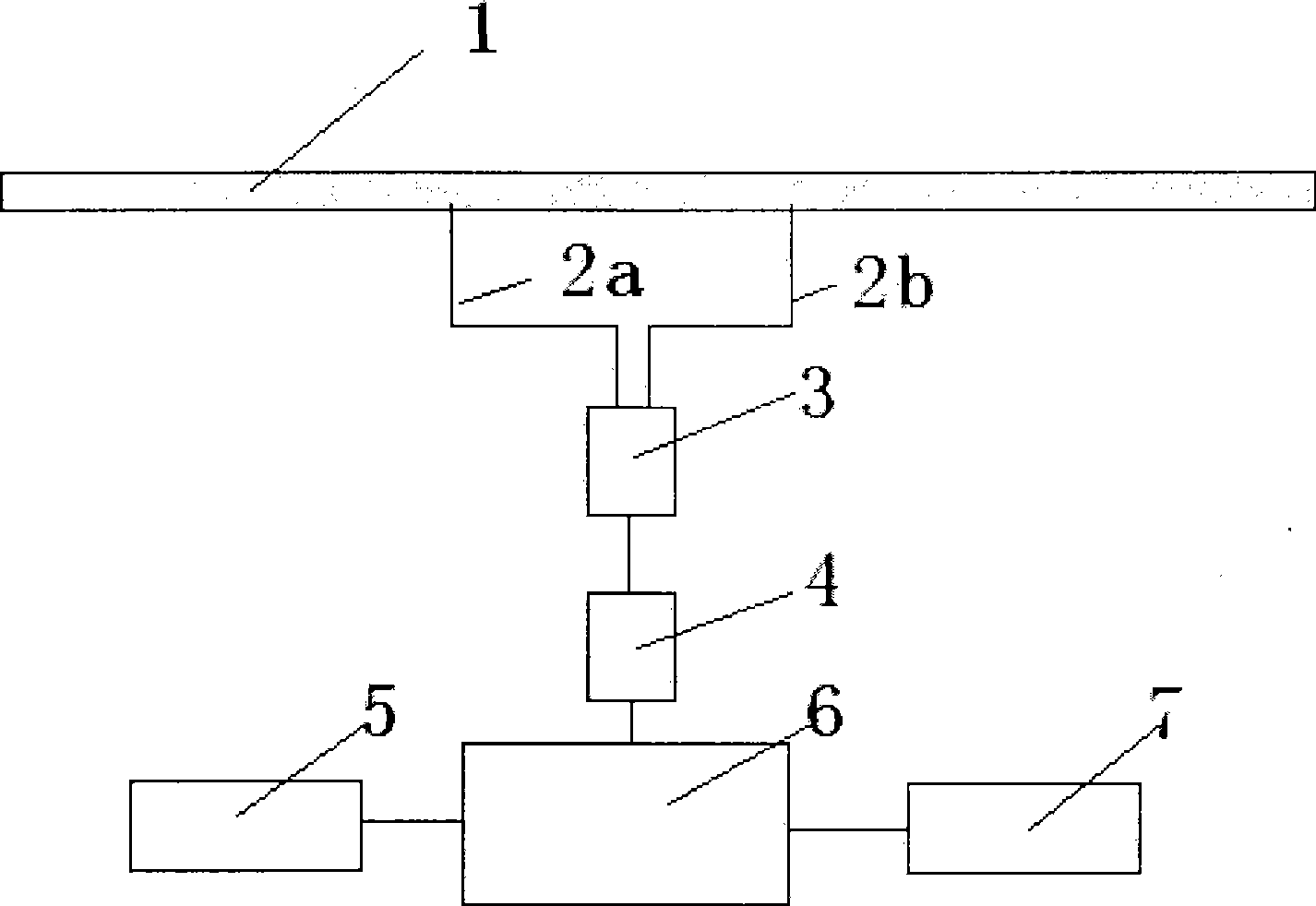

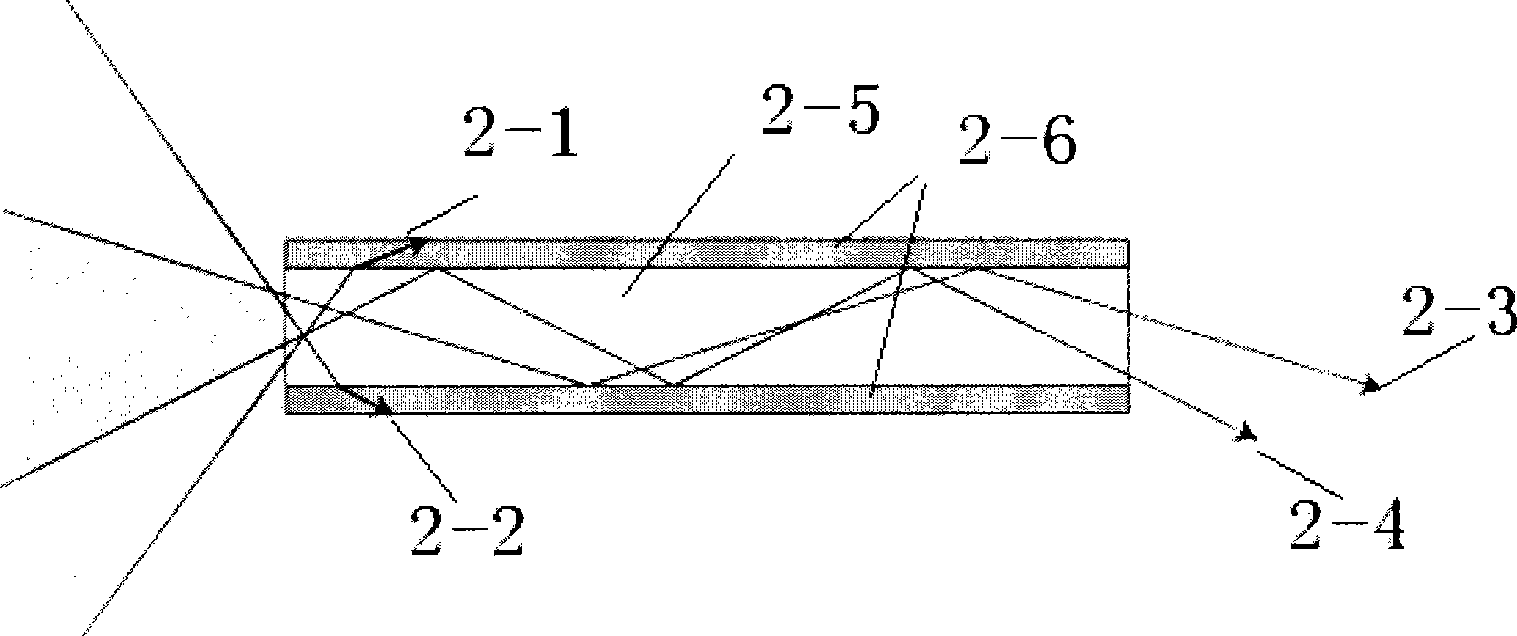

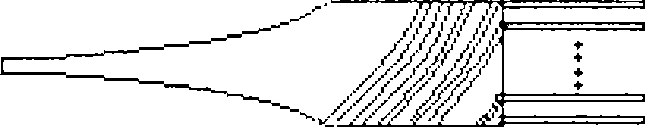

[0016] like figure 1 Shown, detonating cord detonation velocity photoelectric testing device of the present invention comprises two (N) multimode fiber probes (N >= 2) that multimode fiber is made with multimode fiber, and the typical example of this explanation is with two multimode fiber probes 2a, 2b as an example), multi-fiber coupling connector 3, PIN integrated photodetector or solid-state photomultiplier tube detector 4, power supply 5, FPGA high-speed data acquisition module 6 and liquid crystal display 7. The multimode fiber probes 2a, 2b are inserted on the detonating cord 1 at a certain distance, and the two (N) multimode fiber probes are simultaneously connected to a multi-fiber coupling connector, and the multi-fiber coupling connector Connect to the input end of the PIN integrated photodetector or solid-state photomultiplier tube detector through a pigta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com