TFT-LCD color film / array substrate, liquid crystal display panel and method for producing same

A liquid crystal display panel and array substrate technology, which is applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve problems such as image display defects, misalignment of color filters and array substrates, and poor pictures, achieving maximum flexibility and reliability Improved operability, guaranteed image display quality, brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

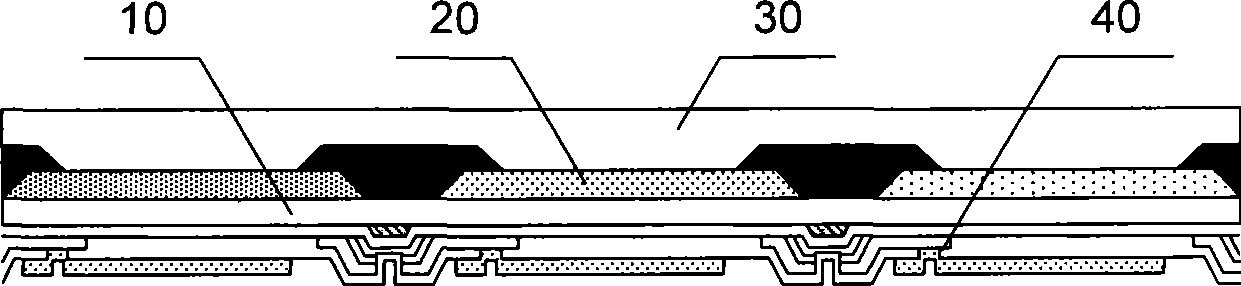

[0045] figure 1 It is a schematic structural diagram of the first embodiment of the TFT-LCD color filter / array substrate of the present invention. Such as figure 1 As shown, the TFT-LCD color filter / array substrate of this embodiment includes a first substrate 10, a color filter layer 20, a transparent layer 30 and an array structure layer 40, wherein the color filter layer 20 is formed on one surface of the first substrate 10, It includes black matrix, red resin, green resin and blue resin; the transparent layer 30 is formed on the color filter layer 20 and has a flat surface; the array structure layer 40 is formed on the other surface of the first substrate 10 .

[0046] The technical solution of this embodiment will be further described below through the preparation process of the TFT-LCD color filter / array substrate of this embodiment.

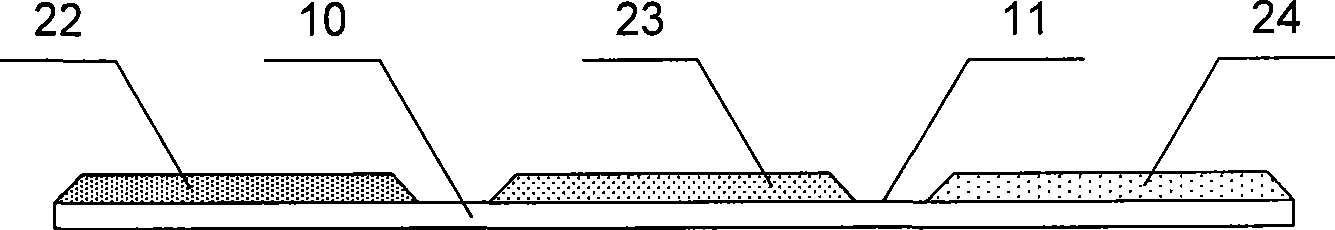

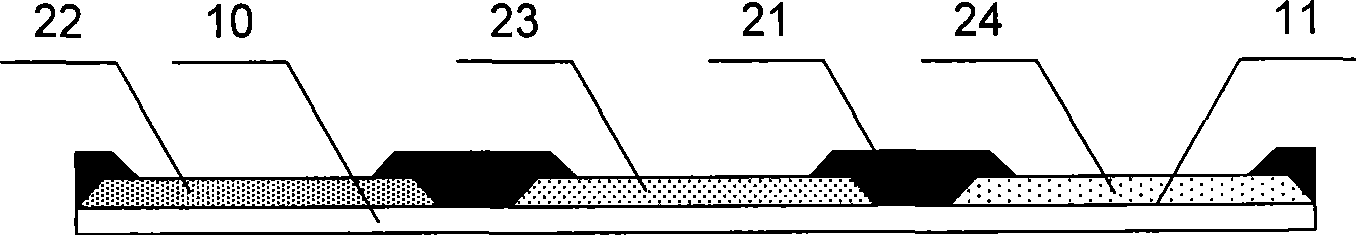

[0047] figure 2 It is a schematic diagram of forming a colored resin according to the first embodiment of the present invention. Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com