Toner, two-component developer, developing device, and image forming apparatus

一种双组分显影剂、调色剂的技术,应用在显影装置及图像形成装置,双组分显影剂,调色剂领域,能够解决流动性下降、区域转印性大、调色剂带电等问题,达到脱模剂量合适、流动性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

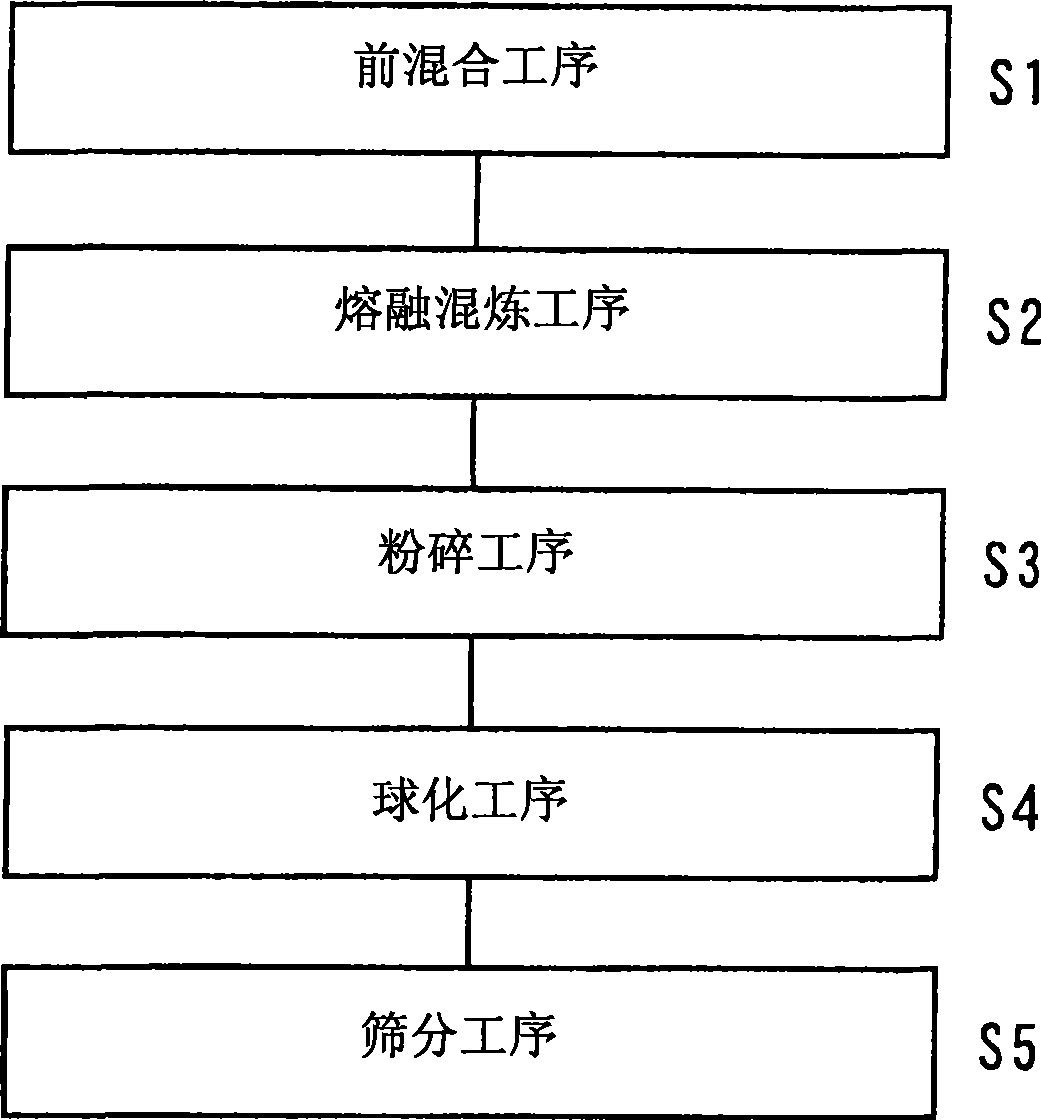

[0151] Polyester (adhesive resin, trade name: FC1494, manufactured by Mitsubishi Rayon Co., Ltd., glass transition temperature (Tg): 62°C, softening temperature (Tm): 127°C) 81.8 parts by weight, masterbatch (containing 40 % by weight of C.I. Pigment Red 57:1) 12 parts by weight, carnauba wax (release agent, trade name: HNP10, manufactured by Nippon Seika Co., Ltd., melting point 75°C) 4.8 parts by weight, metal alkyl salicylate ( Charge control agent, trade name: BONTRON E-84, manufactured by Orient Chemical Co., Ltd.) 1.5 parts by weight, mixed for 10 minutes with a Henschel mixer, and then extruded with a twin-screw mixer (trade name: PCM-65, manufactured by Co., Ltd. Ikegai Co., Ltd.) for melt kneading.

[0152] This melt-kneaded product was coarsely pulverized with a cutting mill (trade name: VM-16, manufactured by Ryoko Sangyo Co., Ltd.), and then finely pulverized with a jet mill. Thereafter, spheroidization was performed using an impact spheroidizer (trade name: Facal...

Embodiment 2

[0156] A toner and a two-component developer of Example 2 were obtained in the same manner as in Example 1 except that the release amount in the pre-mixing step was changed to 4.2 parts by weight. The release amount on the surface of the toner particles was 1.2% by weight.

Embodiment 3

[0158] A toner and a two-component developer of Example 3 were obtained in the same manner as in Example 1 except that the release amount in the pre-mixing step was changed to 3.0 parts by weight. The release amount on the surface of the toner particles was 1.0% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com