Transparent conductive cathode contact structure for n type silicon

A transparent conductive electrode, transparent conductive technology, applied in the direction of circuits, electrical components, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

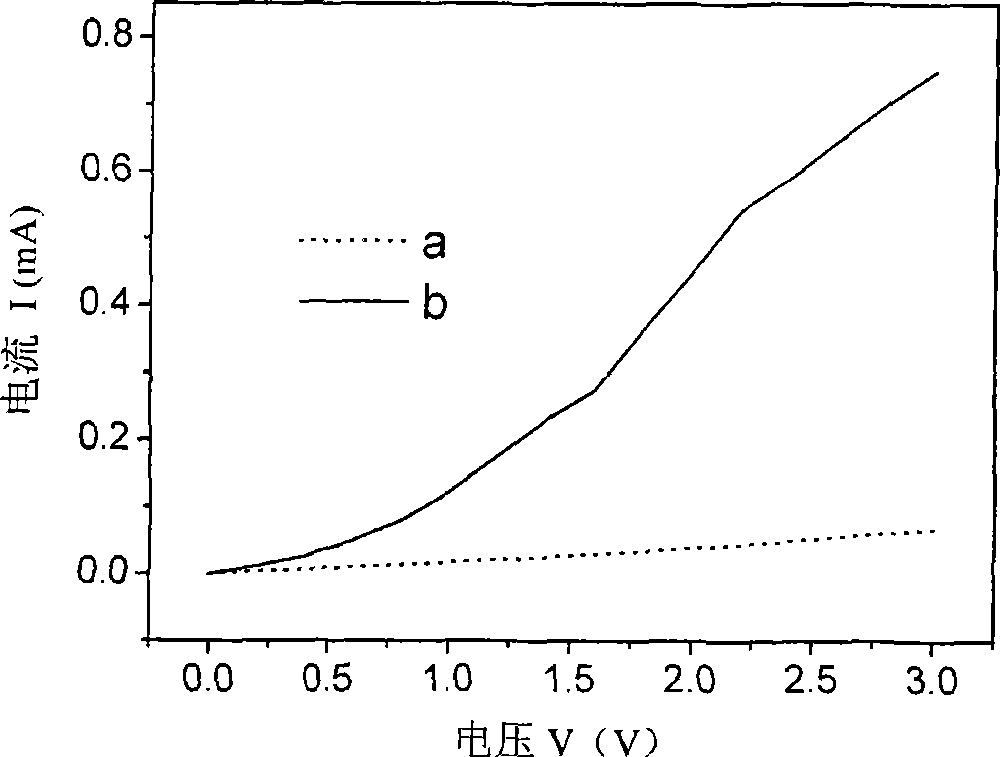

[0025] On the n-type single crystal silicon is a lithium fluoride LiF layer with a thickness of 0.5nm deposited by thermal evaporation, and then on the lithium fluoride LiF layer is an ITO transparent conductive electrode deposited by magnetron sputtering. The work function of the ITO transparent conductive electrode is greater than that of n-type single crystal silicon. figure 2 The I-V effect of this n-type monocrystalline silicon / LiF / ITO electrode is given in , curve a is the I-V curve of n-type monocrystalline silicon / ITO electrode without lithium fluoride LiF intercalation layer, and curve b is the n-type The I-V curve of the single crystal silicon / LiF / ITO electrode is compared. It can be seen that the insertion of the lithium fluoride LiF layer reduces the contact barrier of the n-type single crystal silicon / ITO electrode and improves the electron collection efficiency.

Embodiment 2

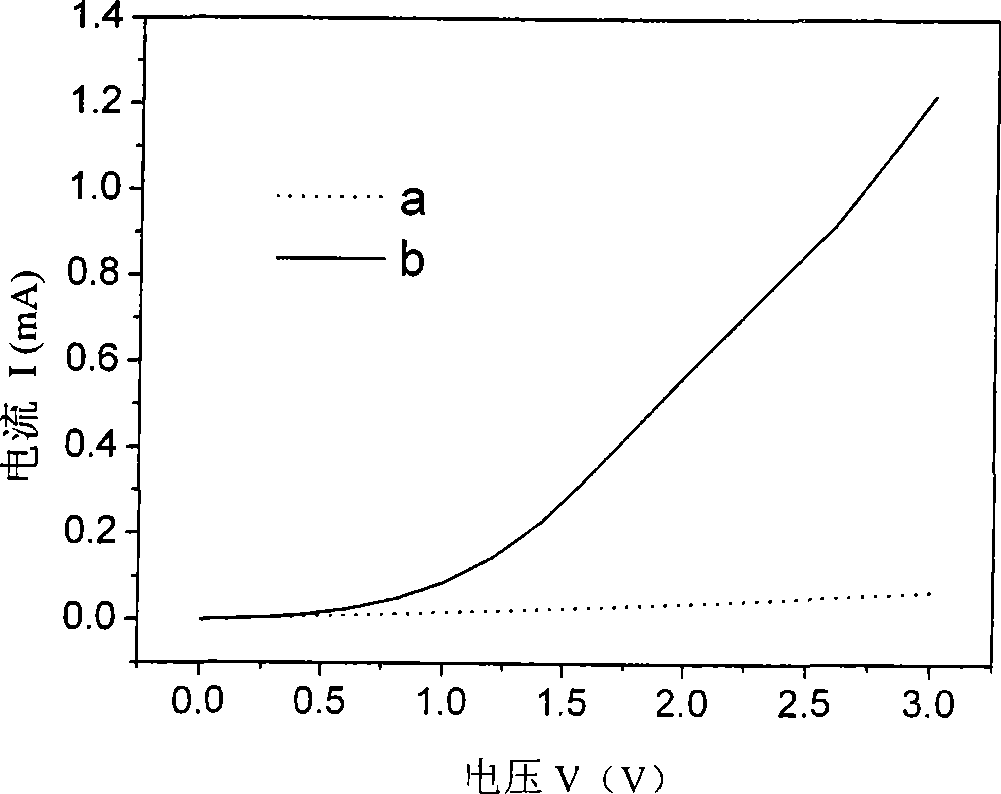

[0027] On the n-type polysilicon is a lithium fluoride LiF layer with a thickness of 1.5nm deposited by thermal evaporation, and then on the lithium fluoride LiF layer is an AZO transparent conductive electrode deposited by magnetron sputtering. The work function of the AZO transparent conductive electrode is greater than that of n-type polysilicon. image 3 The I-V effect of this n-type polysilicon / LiF / AZO electrode is given, the curve a is the I-V curve of the n-type polysilicon / AZO electrode without lithium fluoride LiF intercalation layer, and the curve b is this n-type polysilicon / LiF / AZO electrode It can be seen from the comparison that the insertion of lithium fluoride LiF layer reduces the contact barrier of n-type polysilicon / AZO electrode and improves the electron collection efficiency.

Embodiment 3

[0029] On the n-type amorphous silicon is a lithium fluoride LiF layer with a thickness of 2 nm deposited by thermal evaporation, and then on the lithium fluoride LiF layer is an ITO transparent conductive electrode deposited by magnetron sputtering. The work function of the ITO transparent conductive electrode is greater than that of n-type amorphous silicon. image 3 The I-V effect of this n-type amorphous silicon / LiF / ITO electrode is given in , the curve a is the I-V curve of the n-type amorphous silicon / ITO electrode without lithium fluoride LiF intercalation layer, and the curve b is the n-type amorphous silicon The comparison of the I-V curves of the crystalline silicon / LiF / ITO electrode shows that the insertion of the lithium fluoride LiF layer reduces the contact barrier of the n-type amorphous silicon / ITO electrode and improves the electron collection efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com