Low-sulfate radical sulfamate concentrated liquid preparation method and device thereof

A technology of sulfamate and sulfamic acid, which is applied in the field of preparation of sulfamate concentrate, can solve problems such as high sulfate content, large time and energy consumption, easy decomposition, etc., and achieve high decomposition of sulfate content and save Effects of energy consumption, time, and response time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

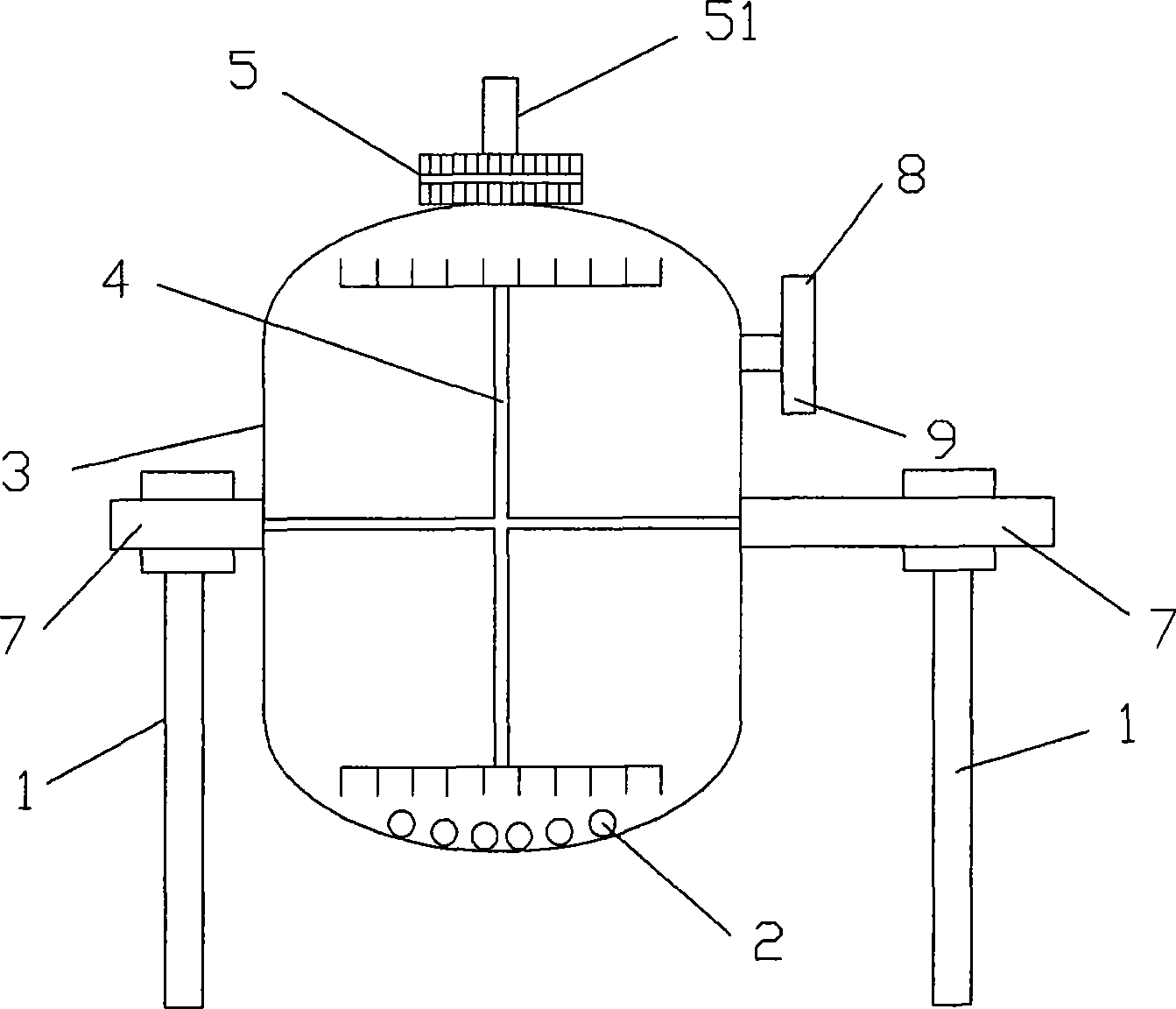

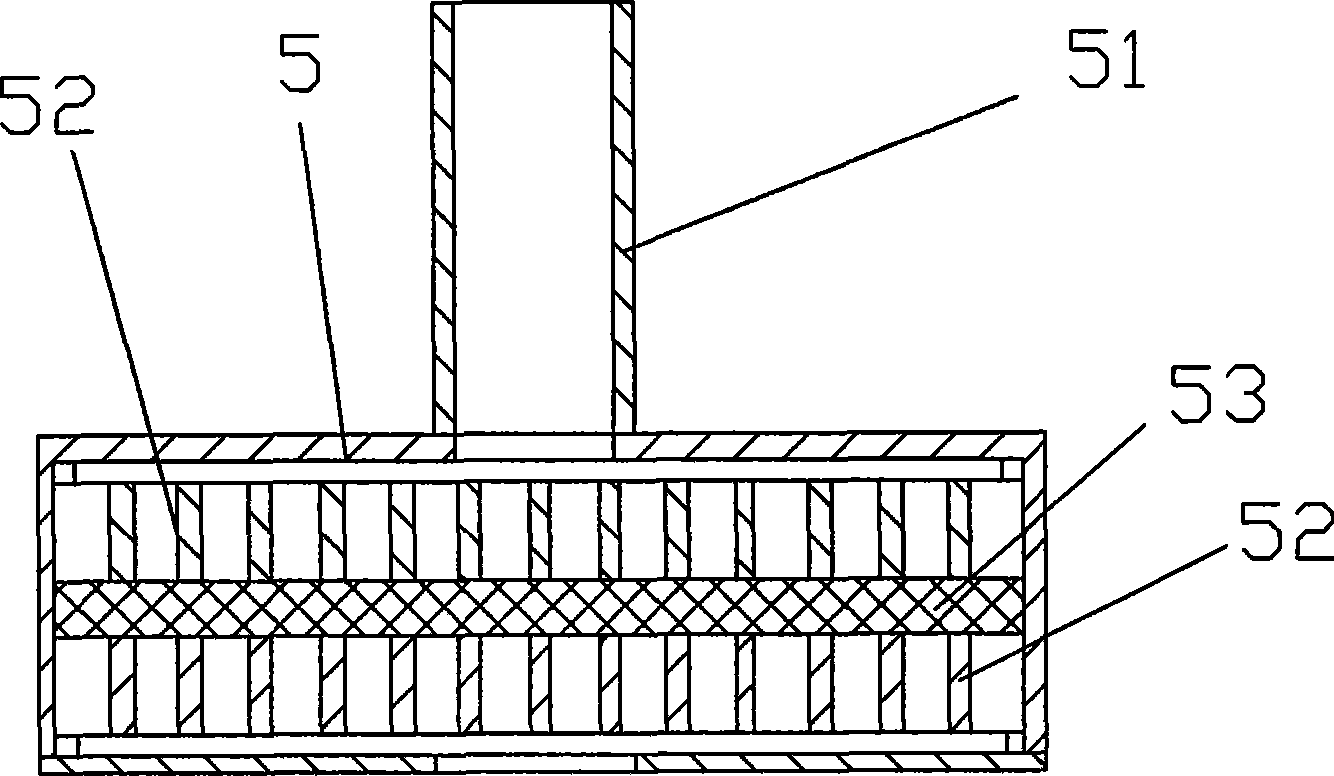

[0039] see figure 1 , 2 , special equipment for the preparation method of low sulfate sulfamate concentrate, the equipment includes: reaction tank body 3, horizontal bar 7, support frame 1, tank cover 5, water inlet 8 with valve, body 1 is circular, The horizontal bar 7 is integrated with the reaction tank body 3, the horizontal bar 7 is fixed on the support frame 3, the tank cover 5 is on the top of one end of the reaction tank body 3, the horizontal bar is connected with the driving device, and the reaction tank body 3 is equipped with a fixed comb type The plow stirring device 4, the body 3 is also provided with a compressed air port 9 with a valve, and a filter device is provided in the tank cover; zirconia balls 2 are also housed in the reaction tank; the tank cover 5 is provided with a discharge valve. There is a discharge port 51 with a valve, and the filter device is a filter cloth 53 sandwiched between two layers of screens 52 .

Embodiment 2

[0041] Preparation method of nickel sulfamate concentrate with low sulfate radical

[0042] (A) by weight

[0043] Nickel carbonate (according to the amount of metal) 18 parts

[0044] 62 parts of dry powdered sulfamic acid

[0045] 85 parts of water;

[0046] (B) Open the cover 5, pour nickel carbonate and dry sulfamic acid into the reaction tank according to the ratio of (A), cover the tank cover 5, the motor drives the horizontal bar 7 to drive the reaction tank body 3 to rotate, and the comb type plow Stirring device 4 and zirconia ball 2 also rotate accordingly, mix and stir for 30 minutes, add hot pure water at 60°C from water inlet 8 according to the ratio (A), close water inlet 8, and stir for another 60 minutes in a closed reaction tank;

[0047] (C) inject compressed air from the compressed air port 9, open the discharge port 51, after the reactant is filtered by the filter device of the tank cover 5, the nickel sulfamate concentrated solution flows out from the d...

Embodiment 3

[0050] Proportion by weight

[0051] 15 parts of metal salt or metal base (according to the amount of metal)

[0052] 65 parts of dry powdered sulfamic acid

[0053] 90 parts of water

[0054] Other repeat embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com