High hardness abrasive resistance bi-component waterborne wood lacquer and preparation method thereof

A water-based wood paint, two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor scratch resistance, poor defoaming, poor leveling, etc., to achieve easy construction, outstanding heat resistance , good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh 18.9kg of deionized water and 65kg of resin, and put in 0.2kg of wetting agent, 0.4kg of defoamer, and 0.3kg of dispersant in sequence at a speed of 300-600 rpm; at a speed of 600-1000 rpm, Sequentially put in nano-SiO 2 0.5kg, glass powder slurry 10kg, matting powder 1.5kg, and then disperse at a high speed for 10-60 minutes at a speed of 1200-1500 rpm; the fineness of the quality inspection is ≤20μm; Membrane aid 3kg, rheological agent 0.2kg, disperse at high speed for 10-30 minutes until there is no shrinkage cavity, and get the main paint component 1 after filtration. Weigh 20.0kg of PMP and 80.0kg of curing agent, mix and stir evenly to obtain component 2. During construction, only need to press component 1: component 2 is 1:0.375 weight ratio, and then manually stir for 5-10 minutes. It can be applied after uniformity.

Embodiment 2

[0051] Weigh 8.5kg of deionized water and 70kg of resin, and put in 0.25kg of wetting agent, 0.35kg of defoamer, and 0.35kg of dispersant in sequence at a speed of 300-600 rpm; at a speed of 600-1000 rpm, Sequentially put in nano-SiO 20.6kg, glass powder 15kg, matting powder 1.2kg, and then disperse at high speed for 10-60 minutes at 1200-1500 rpm; quality inspection fineness ≤ 20μm; at 100-400 rpm, put into film formation in turn Auxiliary agent 3.5kg Rheological agent 0.25kg High-speed dispersion for 10-30 minutes until there is no shrinkage cavity After filtration, the main paint component 1 is obtained. Weigh 25.0kg of PMP and 75.0kg of curing agent, mix and stir evenly to obtain component 2. During construction, it is only necessary to press the weight ratio of component 1: component 2 to be 1:0.43, and then manually stir for 5-10 minutes, and the construction can be carried out after uniformity.

Embodiment 3

[0053] Weigh 1.1kg of deionized water and 75kg of resin, and put in 0.3kg of wetting agent, 0.4kg of defoamer, 17kg of glass powder, and 0.3kg of dispersant at 600-1000 rpm at a speed of 300-600 rpm At the rotating speed, input nano-SiO 2 0.6kg, 1.0kg of matting powder, and then disperse at high speed for 10-60 minutes at 1200-1500 rpm; quality inspection fineness ≤ 20μm; Rheological agent 0.3kg, disperse at high speed for 10-30 minutes until there is no shrinkage cavity, and get the main paint component 1 after filtering. Weigh 30.0kg of PMP and 70.0kg of curing agent, mix and stir evenly to obtain component 2. During construction, you only need to use the weight ratio of component 1:component 2 to be 1:0.5, and then manually stir for 5-10 minutes , can be constructed after uniformity.

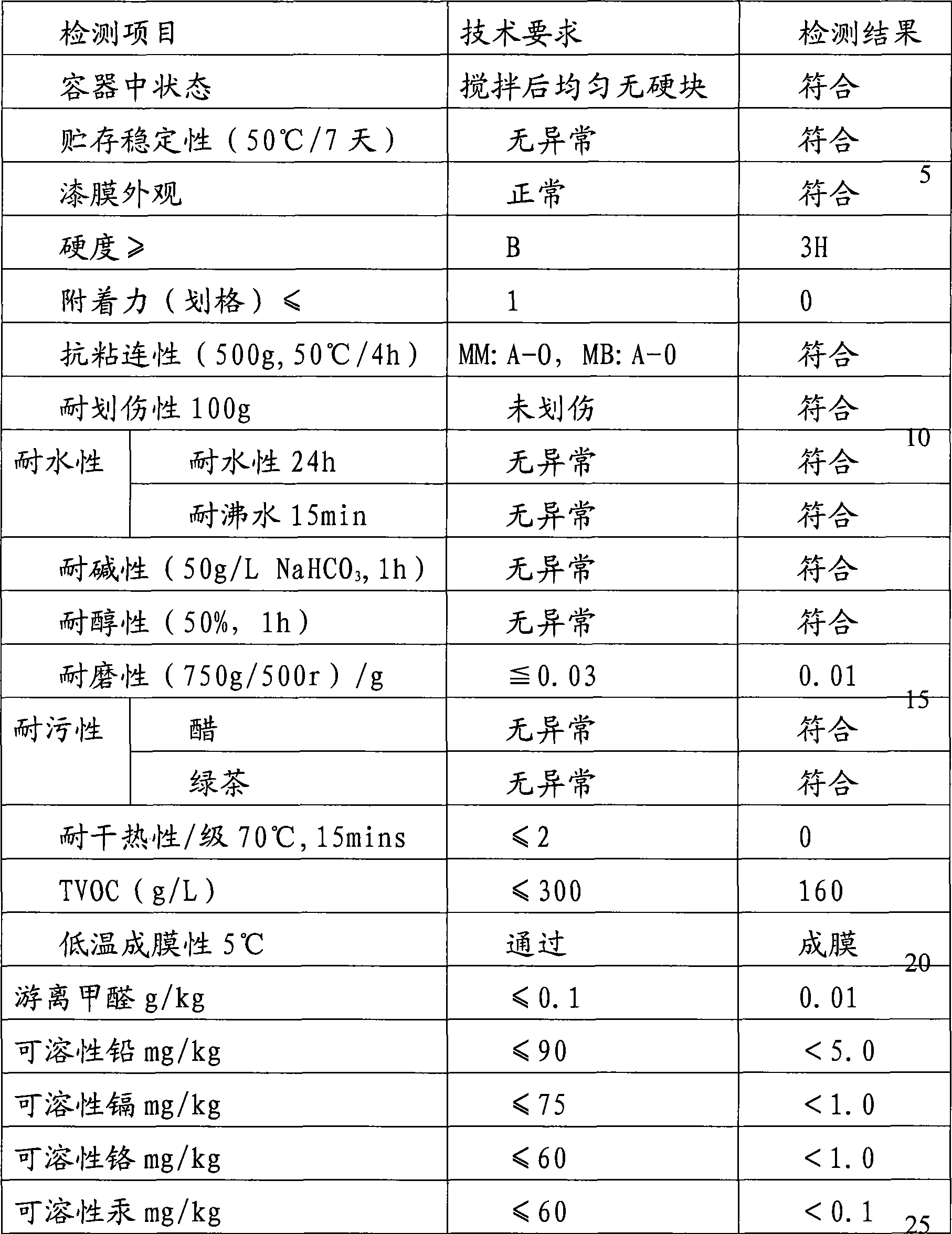

[0054] In the above-mentioned embodiment, the effect after construction and use is shown in the following table 1, and the technical requirements are conventional main technical index requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com