Oil displacement agent suitable for surfactant for low-permeability oilfield, and preparation method thereof

The technology of surfactant flooding and surfactant is applied in the field of oil displacement agent and its preparation, which can solve the problems of not being able to obtain the super oil-water interfacial tension required for oil displacement, blocking formation pores, and destroying formation structure, etc. Conducive to sustainable development, avoiding damage, and maintaining stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] raw material:

[0039] Heavy alkylbenzene sulfonate 40kg, nonylphenol polyoxyethylene ether 8kg, sorbitol polyoxyethylene ether 10kg, sulfonate Gmini surfactant 10kg, n-butanol 2kg, water 30kg.

[0040] Preparation steps:

[0041] (1), under normal temperature and pressure, under normal temperature and pressure, add anionic sulfonate Gmini surfactant, nonionic surfactant and organic solvent into the reaction kettle, and fully stir for 3 hours;

[0042] (2), add 50% of the total water into the reaction kettle, stir for 2 hours, add the remaining water and all organic solvents, stir until uniform, and form an auxiliary agent;

[0043] (3) Finally, add the heavy alkylbenzene sulfonate into the reactor, and mix it evenly with the auxiliary agent to obtain the finished oil displacement agent.

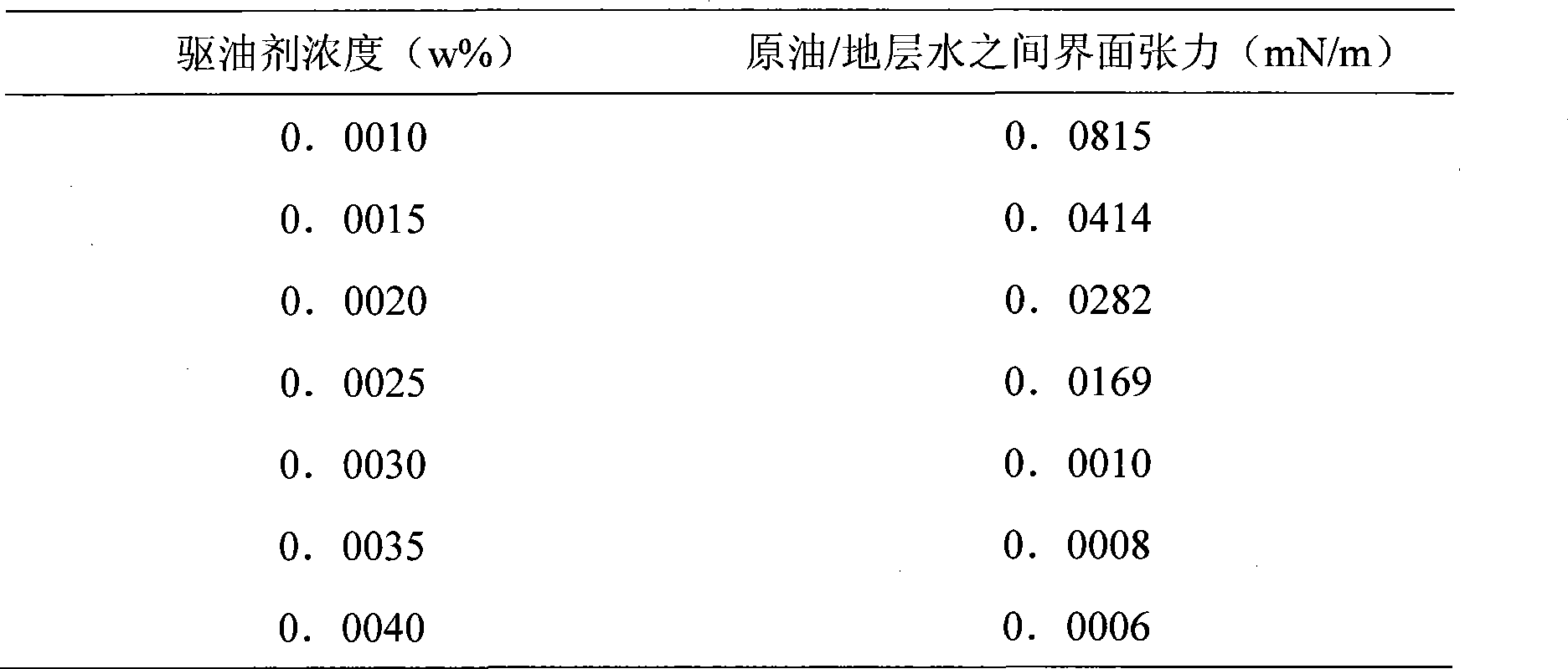

[0044] Test the product for interfacial tension

[0045] 1. Test instrument: 510 spinning drop interfacial tensiometer (SY / T5370-1999)

[0046] 2. Temperature: 50°C

[0047] 3. C...

Embodiment 2

[0053] raw material:

[0054]α-olefin sulfonate 40kg, nonylphenol polyoxyethylene ether 8kg, sorbitol polyoxyethylene ether 10kg, sulfonate Gmini surfactant 10kg, n-butanol 2kg, water 30kg.

[0055] Preparation steps:

[0056] (1), under normal temperature and pressure, under normal temperature and pressure, add anionic sulfonate Gmini surfactant, nonionic surfactant and organic solvent into the reaction kettle, and fully stir for 3 hours;

[0057] (2), add 50% of the total water into the reaction kettle, stir for 2 hours, add the remaining water and all organic solvents, stir until uniform, and form an auxiliary agent;

[0058] (3) Finally, add the α-olefin sulfonate into the reactor, and mix it evenly with the auxiliary agent to obtain the finished oil displacement agent.

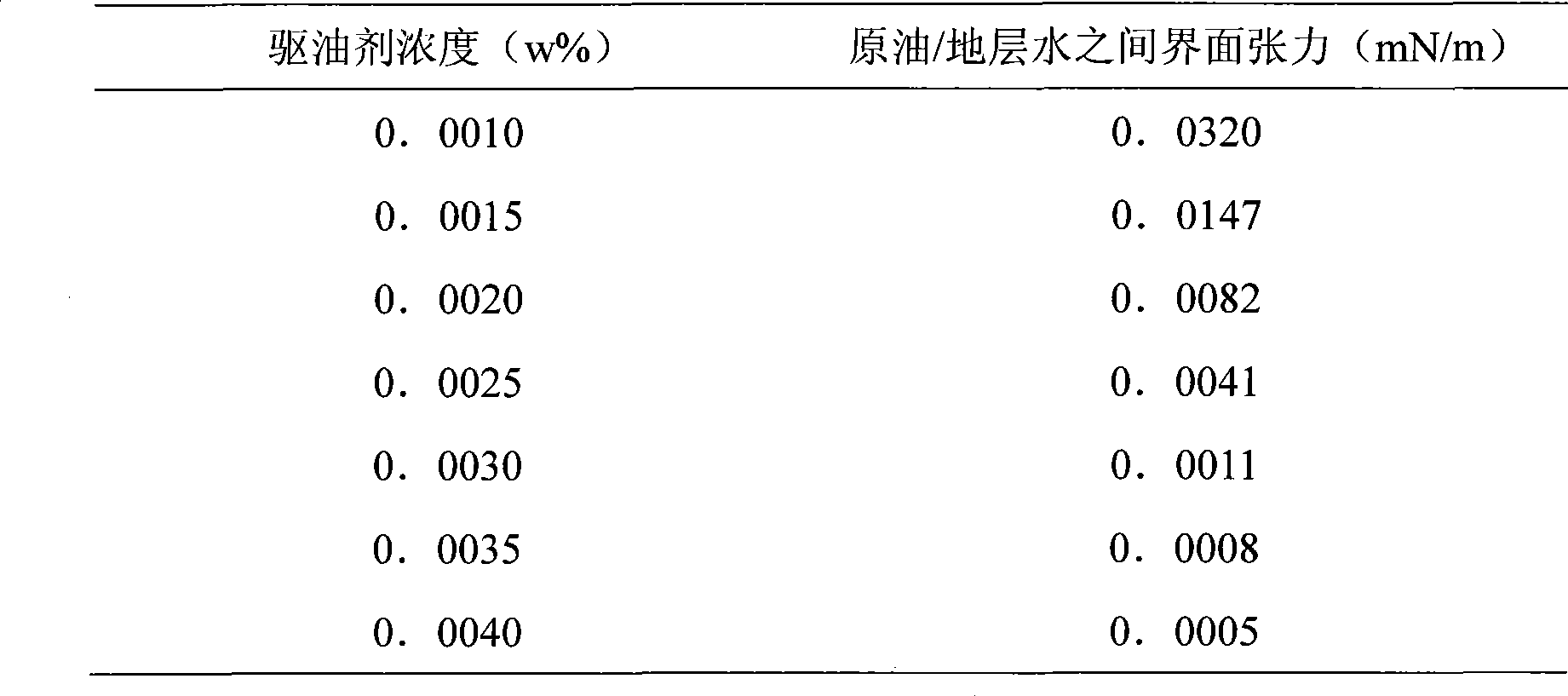

[0059] Test the product for interfacial tension

[0060] 1. Test instrument: 510 spinning drop interfacial tensiometer (SY / T5370-1999)

[0061] 2. Temperature: 80°C

[0062] 3. Crude oil: experimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com