Fiber deep dyeing promoter

A technology of deepening agent and fiber, applied in fiber processing, textile and papermaking, etc., can solve the problem of insufficient performance, and achieve the effect of increasing absorption and reducing reflected light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] a. Synthesis of hydroxy-terminated amino silicone oil:

[0055] Calculated in parts by weight, 96 parts of octamethylcyclotetrasiloxane, 4 parts of -C 3 H 6 NHC 2 H 4 NH 2 The amino coupling agent was added to the reaction kettle, stirred and heated, heated to 90°C for holding at a stirring speed of 60 rpm, after holding for 2 hours, continued to heat to 130°C, and 0.2 parts of 50% NaOH aqueous solution was added as an alkaline catalyst. Increase the temperature to 140°C and keep it for 3 to 4 hours, adjust its viscosity to 1200-3000mPa.S, ammonia value 0.5, and cool to below 60°C to prepare the hydroxyl-terminated amino silicone oil of the following structural formula, and discharge it for later use.

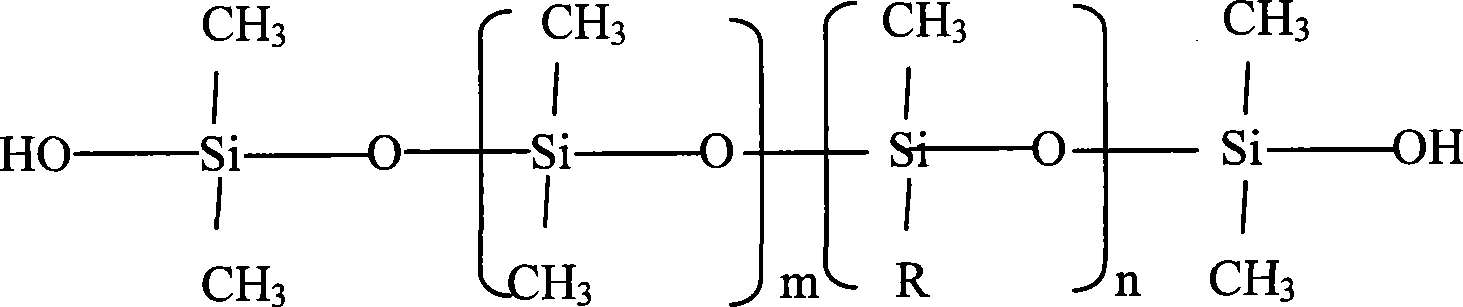

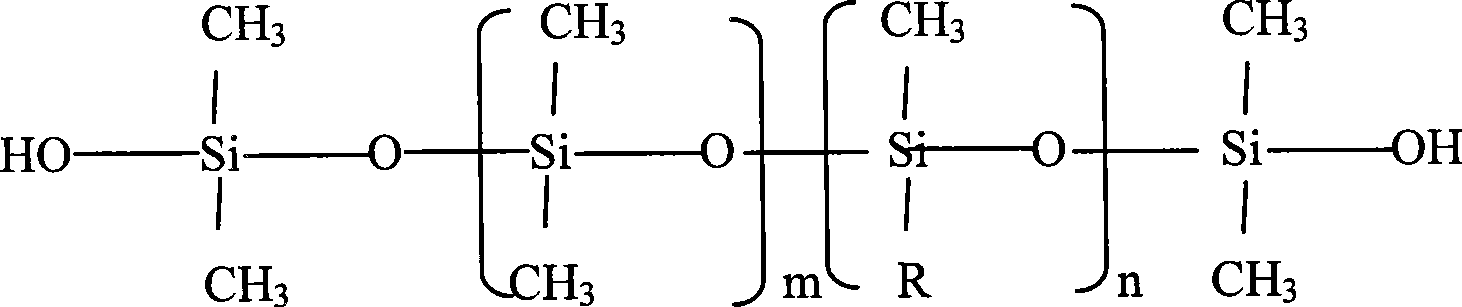

[0056] The structural formula of the hydroxyl-terminated amino silicone oil is as follows:

[0057]

[0058] Among them, R is: -C 3 H 6 NHC 2 H 4 NH 2 , M=100, n=25.

[0059] Synthesis of partial hydrolysate of methyltrimethoxysilane:

[0060] b. Calculated in parts by wei...

Embodiment 2

[0063] a. Synthesis of hydroxy-terminated amino silicone oil:

[0064] Calculated in parts by weight, 94 parts of octamethylcyclotetrasiloxane, 6 parts of -C 3 H 6 NH 2 Add amino coupling agent into the reaction kettle, stir and heat, heat up to 90°C for holding, stirring speed 60 rpm, after holding for 2 hours, continue to heat up to 130°C, add 0.2 parts of 50% potassium hydroxide aqueous solution to make alkaline The catalyst is heated to 140°C for 3 to 4 hours, adjusted its viscosity to 800-2000mPa.S, ammonia value is 0.5, and cooled to below 60°C to prepare a hydroxyl-terminated amino silicone oil of the following structural formula, which is discharged for use.

[0065] The structural formula of the hydroxyl-terminated amino silicone oil is as follows:

[0066]

[0067] Among them, R is: -C 3 H 6 NH 2 , M=210, n=30.

[0068] b. Synthesis of partial hydrolysate of methyltrimethoxysilane:

[0069] Calculated in parts by weight, 80 parts of methyltrimethoxysilane, 17 parts of ...

Embodiment 3

[0072] a. Synthesis of hydroxy-terminated amino silicone oil:

[0073] Calculated in parts by weight, 91 parts of octamethylcyclotetrasiloxane, 9 parts of —CH 3 Add the amino coupling agent to the reaction kettle, stir and heat, heat up to 90°C for holding at a stirring speed of 60 rpm, after holding for 2 hours, continue to heat up to 130°C, add 0.2 parts of 50% BaOH aqueous solution as a basic catalyst, Increase the temperature to 140°C and keep it for 3 to 4 hours, adjust its viscosity to 600-1500mPa.S, ammonia value 0.5, and cool to below 60°C to prepare hydroxyl-terminated amino silicone oil of the following structural formula, and discharge it for later use.

[0074] The structural formula of the hydroxyl-terminated amino silicone oil is as follows:

[0075]

[0076] Among them, R is: —CH 3 , M=310, n=50.

[0077] b. Synthesis of partial hydrolysate of methyltrimethoxysilane:

[0078] Calculated in parts by weight, 80 parts of methyltrimethoxysilane, 17 parts of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com