Method for preparing transparent low resistance/high resistance composite membrane used for thin-film solar cell

A technology of solar cells and composite films, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as complex processes, and achieve the effects of reducing production costs, shortening production cycles, and reducing production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

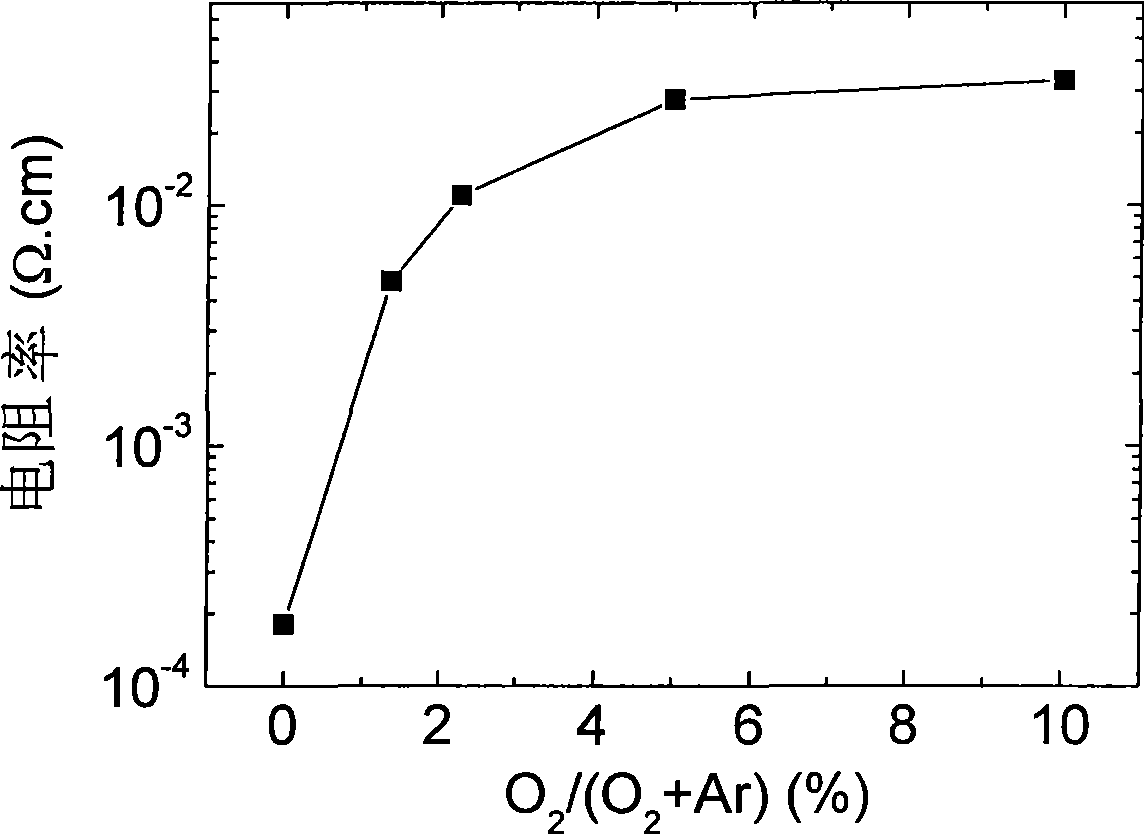

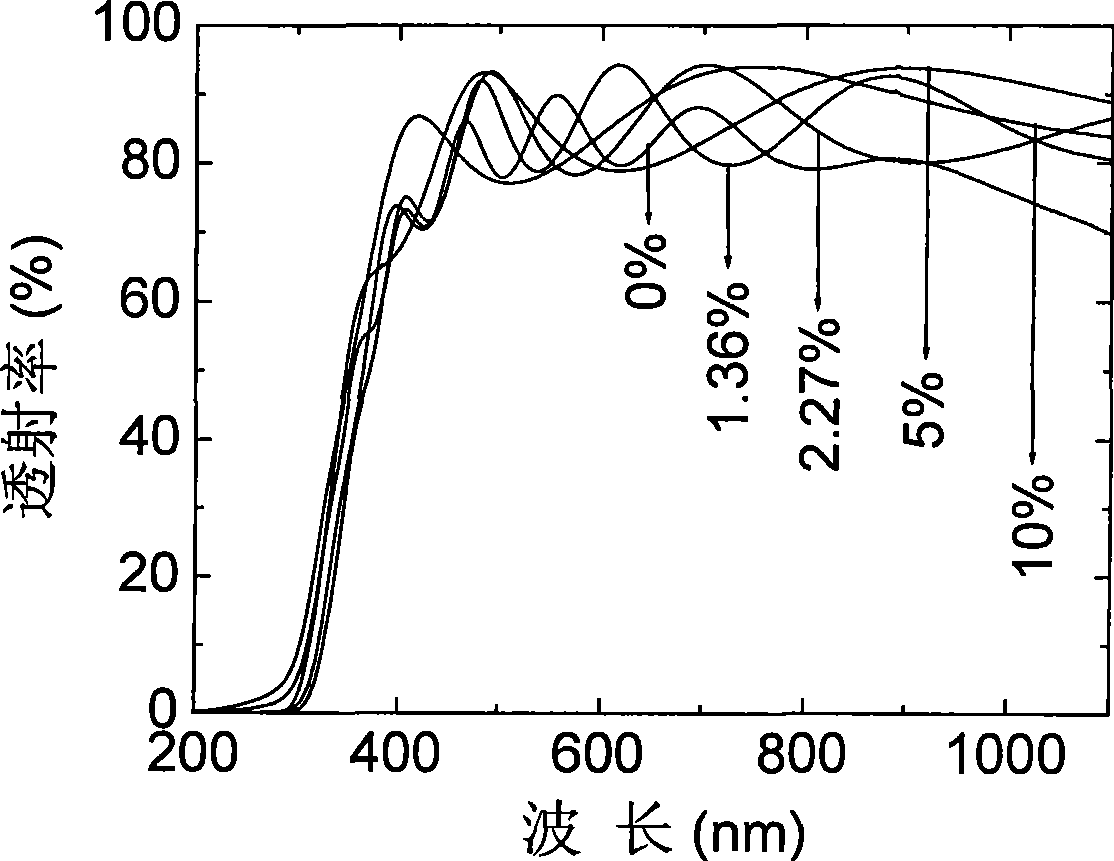

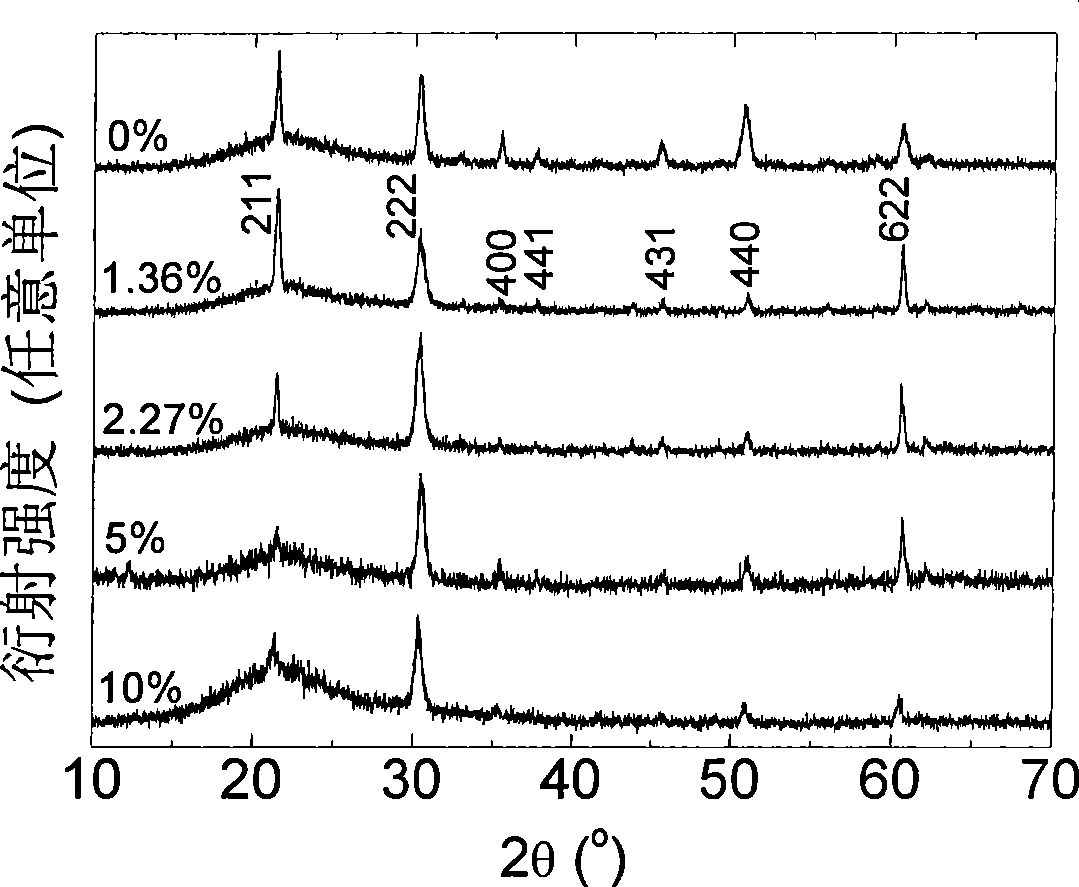

[0028] For the In of the upper layer configuration of the solar cell 2 o 3 : Sn transparent low-resistance / high-resistance composite film growth as an example, using radio frequency magnetron sputtering technology, the quartz glass substrate and In 2 o 3 : Sn sputtering target placed in the vacuum chamber of magnetron sputtering equipment, In2 o 3 : Sn target contains 10wt% SnO 2 , using mechanical pump and molecular pump to pump the vacuum chamber to 6×10 -4 Pa background vacuum.

[0029] Sputtering parameter setting: the sputtering power is 60W, the sputtering pressure is 1.6Pa, and the substrate temperature is 350°C.

[0030] Growth of transparent low-resistance / high-resistance composite films

[0031] On a transparent quartz glass substrate, a transparent low-resistance film was grown by sputtering under pure Ar sputtering gas for 55 min, and then on the transparent low-resistance film in O 2 10% Ar, O 2 Under the mixed sputtering gas, the transparent high-resistan...

Embodiment 2

[0034] Taking the growth of ZnO:Al transparent low-resistance / high-resistance composite film used for solar cells on the upper layer as an example, using radio frequency magnetron sputtering technology, the quartz glass substrate and ZnO:Al sputtering target are placed in the magnetron sputtering equipment In the vacuum chamber, the ZnO:Al target contains 2wt% Al 2 o 3 , using mechanical pump and molecular pump to pump the vacuum chamber to 6×10 -4 Pa background vacuum.

[0035] Sputtering parameter setting: the sputtering power is 80W, the sputtering pressure is 1.6Pa, and the substrate temperature is 420°C.

[0036] Growth of transparent low-resistance / high-resistance composite films

[0037] On a transparent quartz glass substrate, a transparent low-resistance film was grown by sputtering under pure Ar sputtering gas, and the sputtering time was 50 min, and then on the transparent low-resistance film, in O 2 5% Ar, O 2 Under the mixed sputtering gas, the transparent hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com