Copper zincium tin sulfur compound semiconductor thin-film solar cell and manufacturing method

A solar cell, copper-zinc-tin-sulfur technology, applied in the direction of semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems that limit the development of CIGS thin-film solar cells and the content is poor, and achieve the effect of environmental friendliness and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

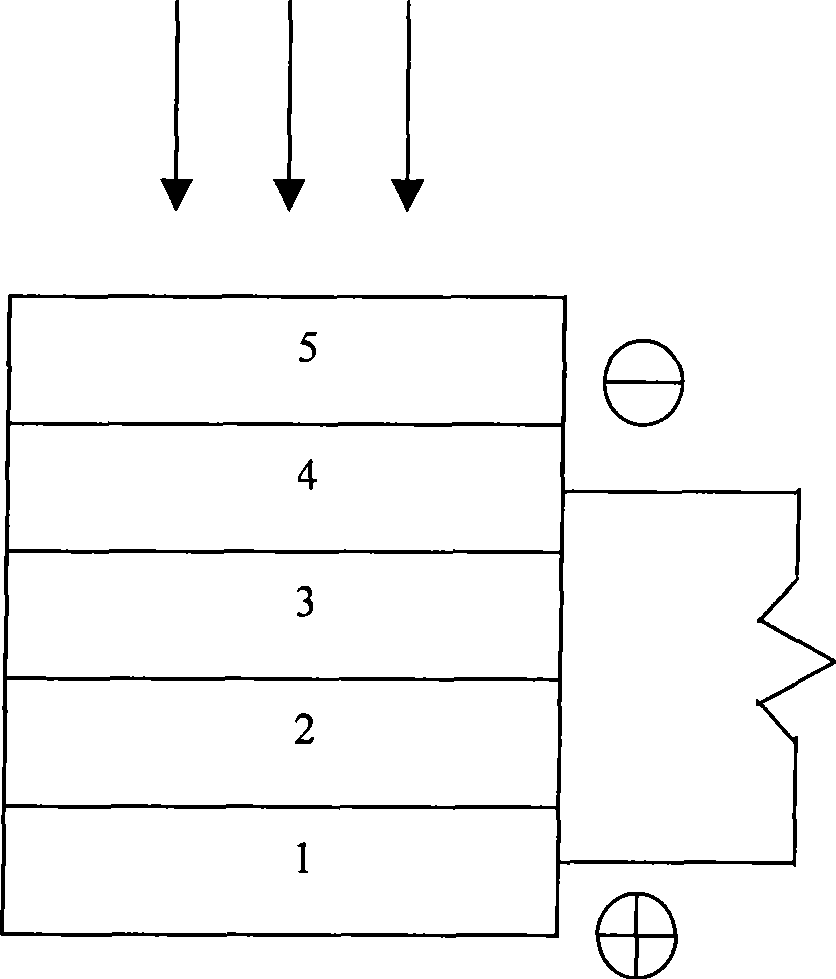

[0024] See figure 1 , the thin-film solar cell of the present invention comprises: a glass substrate 1, on which a metal back electrode layer 2 is sequentially deposited, and a P-type Cu 2 ZnSnS 4 Absorbing layer 3, n-type CdS buffer layer 4, transparent conductive oxide film window layer 5.

[0025] The preparation process of the present embodiment is as follows:

[0026] 1. Deposit a metal gold back electrode layer 2 on the surface of the glass substrate 1 by magnetron sputtering. Then deposit P-type Cu on the back electrode layer 2 ZnSnS 4 The absorption layer 3 has a thickness of 2000 nanometers.

[0027] 2. Then for P-type Cu 2 ZnSnS 4 The absorption layer 3 is post-treated, and the specific steps of the post-treatment are as follows:

[0028] 2A.Cu 2 ZnSnS 4 The post-sulfurization treatment of the absorber layer 3 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com