Tape base and adhesive tape

A base material, aromatic vinyl technology, applied in adhesives, adhesive types, transportation and packaging, etc., can solve the problems of low oil resistance, softness, hand tearing and abrasion resistance of adhesive tapes, etc. problem, to achieve the effect of excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Hereinafter, the present invention will be described in more detail based on examples, but the explanation of the present invention is not limited to these examples. It should be noted that units such as "part" and "%" are expressed on a mass basis unless otherwise specified.

[0089] The analysis of the copolymer obtained in the Example was implemented by the following method.

[0090] .

[0091] Using α-500 manufactured by JEOL Ltd., the measurement was performed based on TMS using a heavy 1,1,2,2-tetrachloroethane solvent. The TMS-based measurement referred to here refers to the measurement described below. First, the shift value of the central peak of the triplet 13C-NMR peak of heavy 1,1,2,2-tetrachloroethane was determined based on TMS.

[0092] Next, dissolve the copolymer in heavy 1,1,2,2-tetrachloroethane, measure 13C-NMR, and calculate based on the triplet central peak of heavy 1,1,2,2-tetrachloroethane Each peak displacement value. The shift value of the...

Synthetic example 1

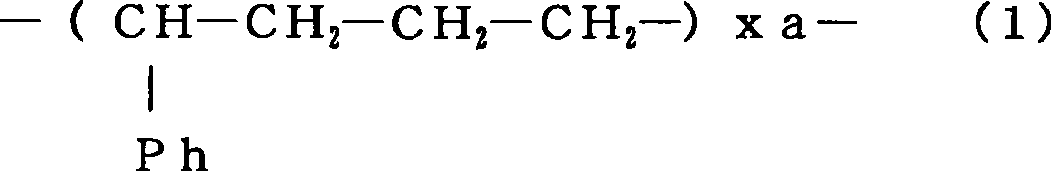

[0132] (Synthesis of ethylene-aromatic vinyl compound copolymer with isotactic stereoregularity)

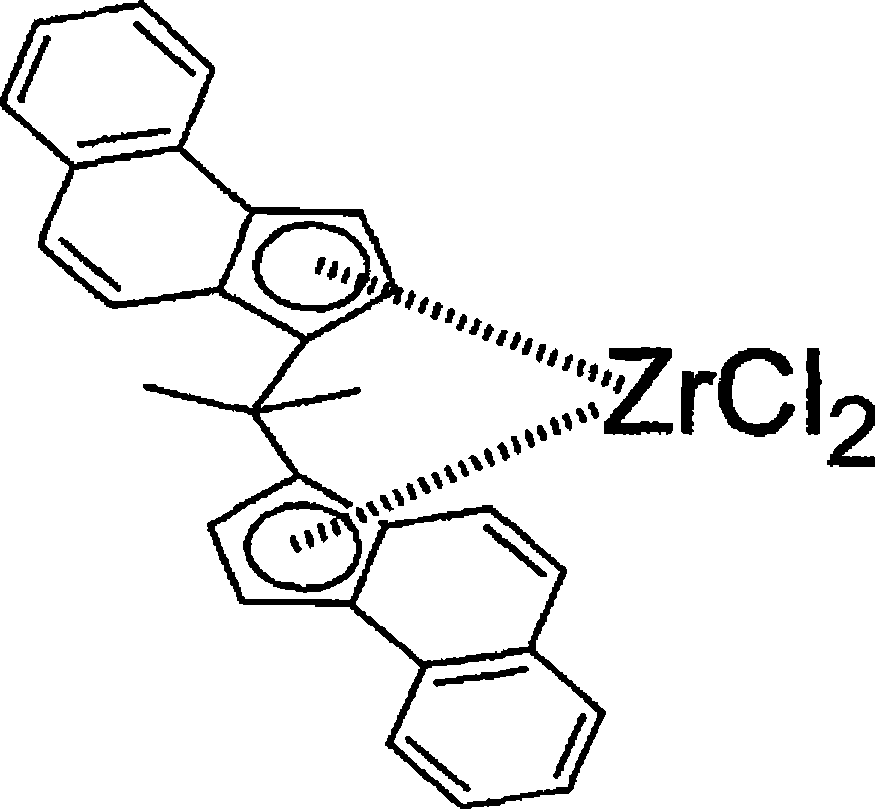

[0133] As a catalyst, use figure 1 The indicated rac-dimethylmethylenebis(4,5-benzo-1-indenyl)zirconium dichloride was carried out as described below.

[0134] Polymerization was carried out using an autoclave having a capacity of 10 L and equipped with a stirrer and a jacket for heating and cooling. Put 1900ml of styrene and 2900ml of cyclohexane into the autoclave, heat and stir until the inner temperature is 60°C. Then, about 100 L of nitrogen was bubbled to purify the inside of the system and the polymerization solution. Then, 8.4mmol of triisobutylaluminum and 16.8mmol of methylalumoxane (manufactured by TOSOHFINECHEM Co., Ltd., MMAO-3A) based on Al were added, and ethylene was immediately introduced to stabilize at a pressure of 0.98MPa (10Kg / cm2G). , 8.4 μmol of rac-dimethylmethylene bis(4,5-benzo-1-indenyl) zirconium dichloride, dissolved in triisobutyl The toluene so...

Synthetic example 2

[0137] The styrene used was changed to 2400 ml, the cyclohexane was changed to 3600 ml, the ethylene pressure was changed to 0.6 MPa, the amount of catalyst was changed to 16.8 μmol, and the polymerization was changed to 1 hour and 50 minutes, in the same manner as in Synthesis Example 1 Carried out to obtain 920 g of polymer B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com