High temperature and high sensitivity piezoelectric ceramic material and preparation method thereof

A high-sensitivity, piezoelectric ceramic technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of low sensitivity of piezoelectric transducers, lack of piezoelectric ceramic materials, and poor performance. Stability and other issues, to achieve the effect of high operating temperature, excellent comprehensive performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] with Pb 3 o 4 (industrial pure), ZrO 2 (industrial pure), TiO 2 (industrial pure), SrCO 3 (industrial pure), Nb 2 o 5 (industrial pure), La 2 o 3 (chemically pure), Cr 2 o 3 (chemically pure), SiO 2 (chemically pure) as raw material, according to 0.53PbZrO 3 +0.38PbTiO 3 +0.01PbNbO 3 +0.05SrTiO 3 +0.03LaTiO 3 +0.05wt.% SiO 2 +0.04wt.%Cr 2 o 3 +0.03wt.%Nb 2 o 5 Stoichiometric weighing, with deionized water and agate balls as the medium, after barrel milling for 8 hours, after discharging and drying, perform the first stage of briquette synthesis at 650°C / 2h, and then carry out the second stage at 850°C / 2h Synthesis, after crushing, barrel milling for 24 hours, discharge drying, adding binder, molding (molding pressure is 150MPa), plastic discharge (800°C / 1h), sintering (1300°C / 2), cold processing, ultrasonic cleaning, Oxidation treatment, upper electrode, polarization (180°C, 3.5kv / mm, 30min), aging treatment (200°C / 2h) and other processes, and finall...

Embodiment 2

[0016] with Pb 3 o 4 (industrial pure), ZrO 2 (industrial pure), TiO 2 (industrial pure), SrCO 3 (industrial pure), Nb 2 o 5 (industrial pure), La 2 o 3 (chemically pure), Cr 2 o 3 (chemically pure), SiO 2 (chemically pure) is raw material, and preparation technology is with embodiment 1, according to 0.53PbZrO 3 +0.40PbTiO 3 +0.01PbNbO 3 +0.03SrTiO 3 +0.03LaTiO 3 +0.04wt.%SiO 2 +0.05wt.%Cr 2 o 3 +0.04wt.% La 2 o 3 chemical formulations for preparation. The main properties of the obtained material standard sheet are: d 33 =492pC / N, ε 33 T / ε o =1824, g 33 =30.5, tgδ=1.7, Kp=0.615, Qm=63, Tc=348°C, ρ v (200°C)=4.7×10 8 Ω cm;

Embodiment 3

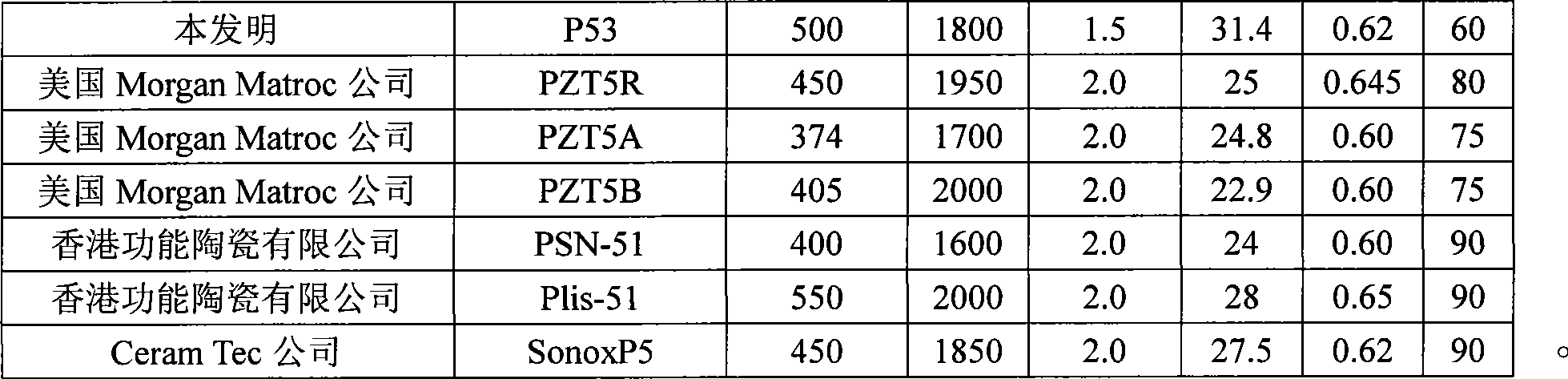

[0018] with Pb 3 o 4 (industrial pure), ZrO 2 (industrial pure), TiO 2 (industrial pure), SrCO 3 (industrial pure), Nb 2 o 5 (industrial pure), La 2 o 3 (chemically pure), SiO 2(chemically pure) is raw material, and preparation technology is with embodiment 1, according to 0.53PbZrO 3 +0.425PbTiO 3 +0.005PbNbO 3 +0.01SrTiO 3 +0.03LaTiO 3 +0.05wt.% SiO 2 +0.04wt.%Nb 2 o 5 +0.05wt.%La 2 o 3 chemical formulations for preparation. The main properties of material standard sheets are: d 33 =500pC / N, ε 33 T / ε o =1800, g 33 =31.4, tgδ=1.5, Kp=0.62, Qm=60, Tc=352°C, ρ v (200°C)=7.8×10 8 Ω cm;

[0019] Table 1 The present invention compares with prior art

[0020]

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com