Method for preparing melamine phosphonate flame-retardant-anti-crease integrated dressing agent for cotton

A technology of melamine and phosphonate, which is applied in fiber processing, textile and papermaking, plant fiber and other directions, can solve the problems of unfriendly environment, low bond energy, etc. The effect of facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

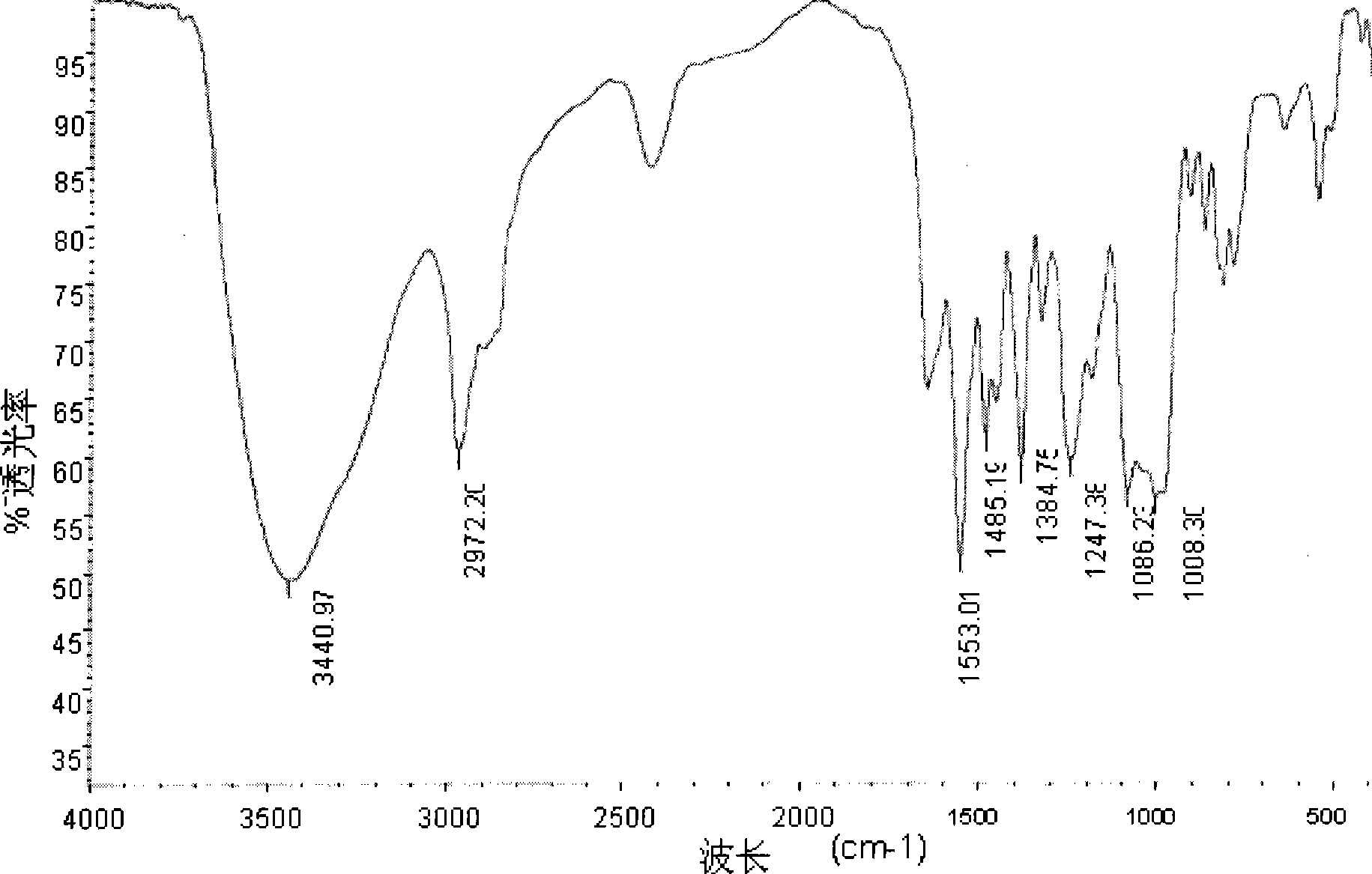

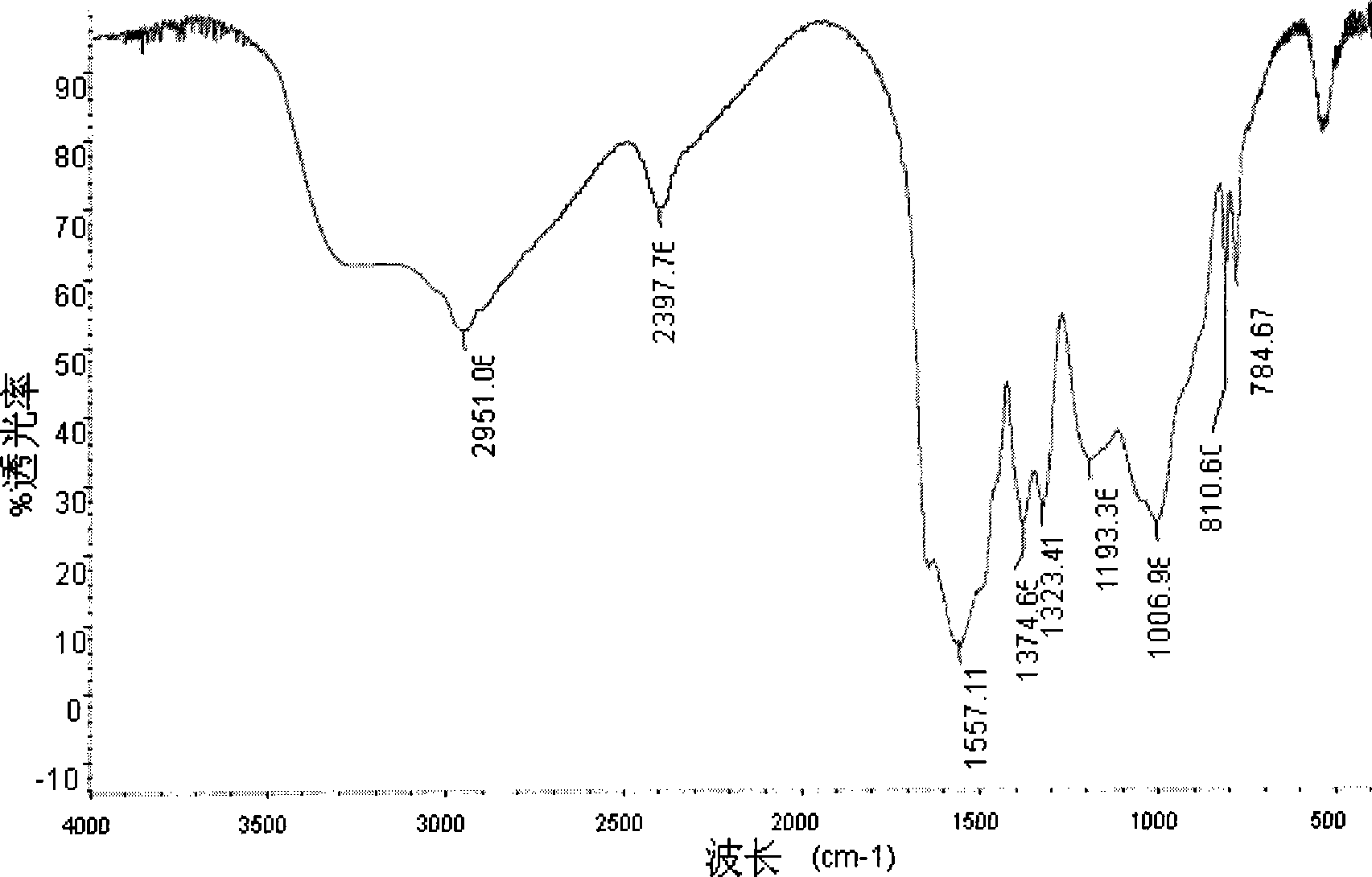

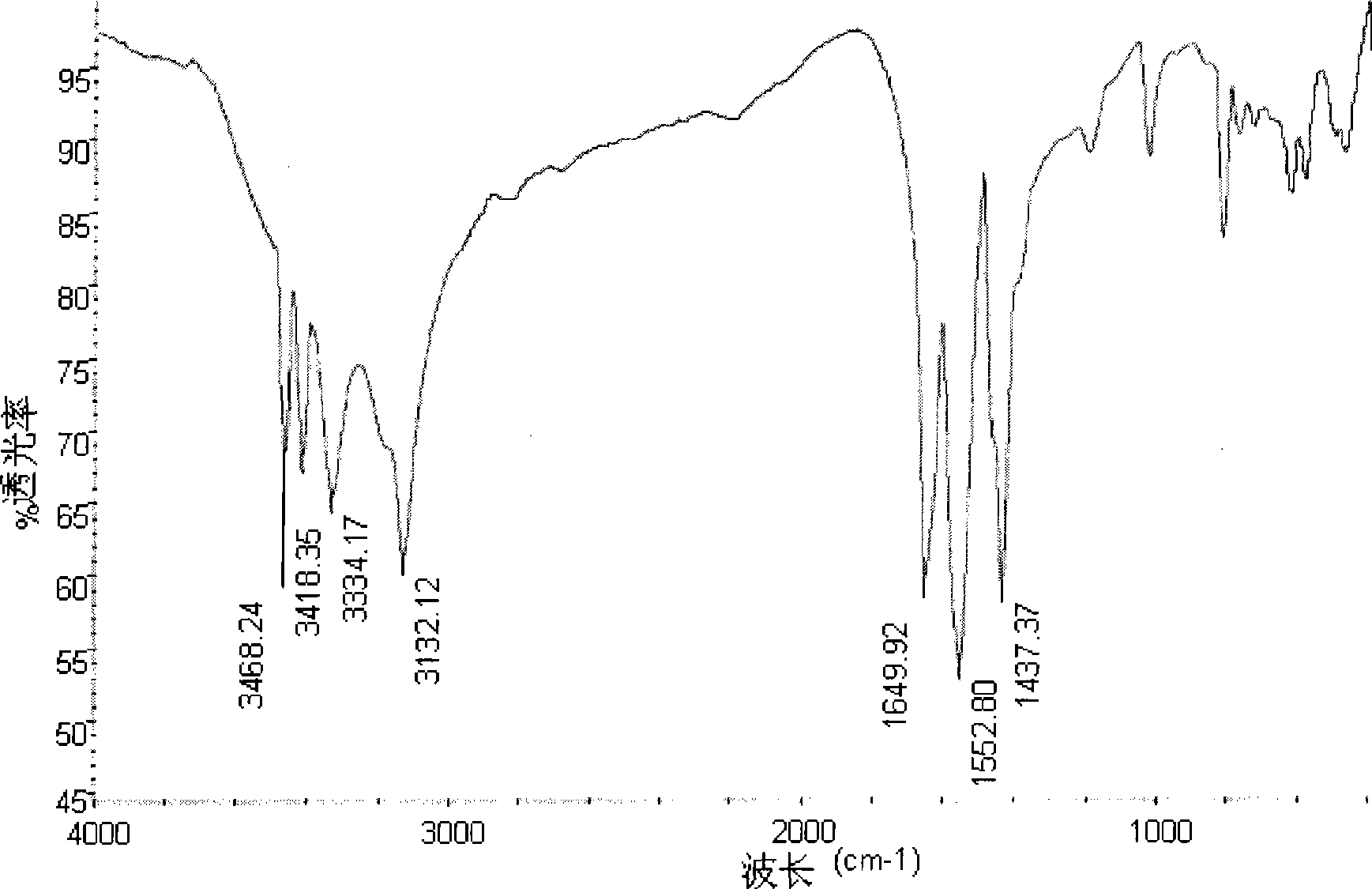

Image

Examples

Embodiment 1

[0030] (1) Preparation of reactive melamine phosphonate flame retardant-anti-wrinkle integrated finishing agent FR15 for cotton

[0031] Take 76.1g of 37% formaldehyde, 12.1g of water, stir, adjust the pH=9.0 with 10% NaOH solution, put in 11.8g of melamine, raise the temperature, control the exothermic reaction, keep it warm at 70°C-100°C until the crystals are precipitated, then let it stand Cool down after 3-4 hours of heat preservation, separate waste water and free formaldehyde, and dry at 55°C to obtain product (I) with a water content of <15%.

[0032] Put 64.6g of methanol into the reactor, adjust the pH to 2.0 with hydrochloric acid, add 32.7g of the product (I), continue to keep warm for 15-30min after the product (I) is completely dissolved, adjust the pH to 9.0 with NaOH, filter to remove salt, and vacuum The product (II) was obtained by filtering the excess methanol.

[0033] Add 106.34g of product (II) and 67.38g of dimethyl phosphite into a four-necked flask, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com