Environment protection hydrogen preparing and supplying method for vehicle and hydrogen engine

A supply method, hydrogen technology, applied in the direction of engine components, machines/engines, container filling methods, etc., can solve the problems of low toxicity, etc., achieve the effects of fewer production and processing procedures, high thermal efficiency, and good environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is characterized in that carrying out according to the following steps:

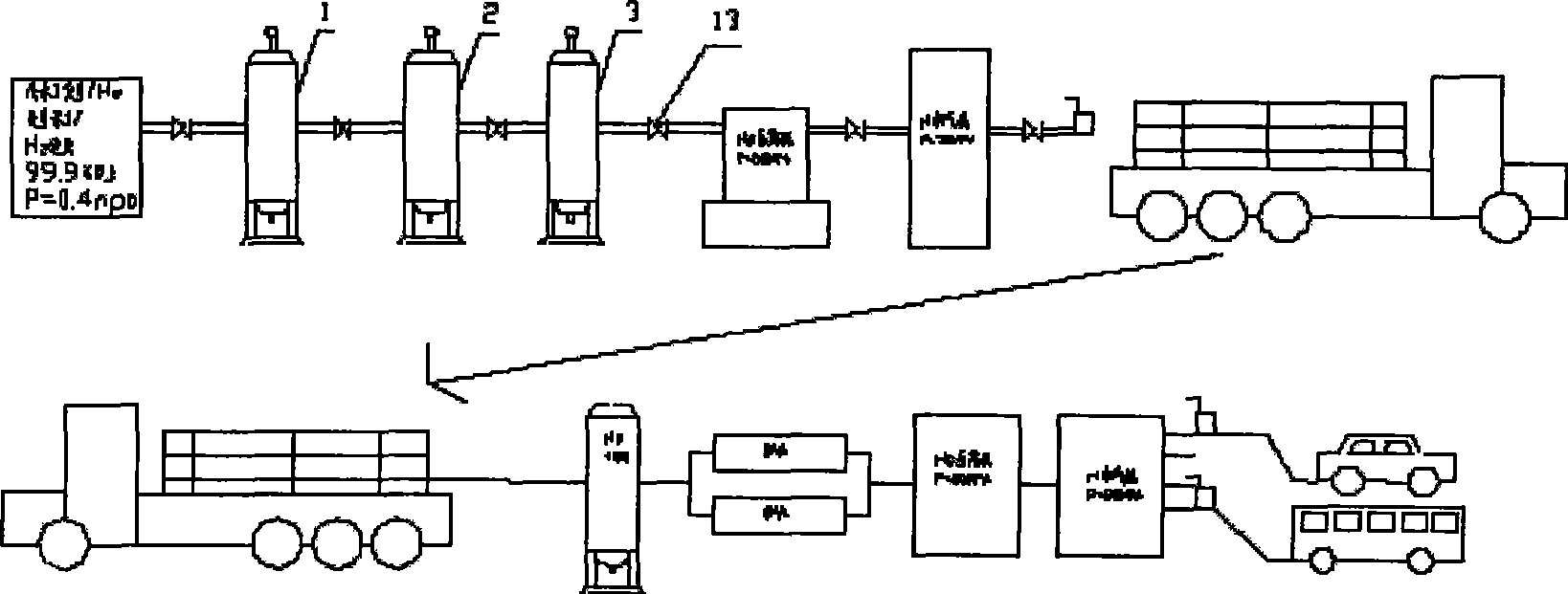

[0018] (1) Produce H with a purity of more than 99.9% and P=0.4Mpa from pure water 2 , and then pass through the first gas storage tank, the second gas storage tank, and the third gas storage tank in turn, and then the H that can produce P=30Mpa 2 compressed by the compressor, and finally through the H that can P=30Mpa 2 The gas filling machine is sent into the gas storage tank of the transport vehicle;

[0019] (2) Transport the gas storage tank to the gas filling station, and connect the gas outlet of the gas storage tank to the gas pipeline, H 2 Through the gas pipeline first through H 2 desiccator to remove H 2 The moisture in the gas enters the gas storage tank, and then enters the H with P=30Mpa from the output port of the gas storage tank. 2 Compressed by the compressor, and finally fed into H with P=30Mpa 2 Gas filling machine, add H to the fuel tank of the vehi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com