Injection type electrostatic sorting method and apparatus

An electrostatic separation and spray technology, applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve problems such as inability to effectively separate micron-sized fine-grained minerals, huge investment in industrial wastewater, and industrial wastewater pollution. To achieve the effect of good sorting effect, wide material source and clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

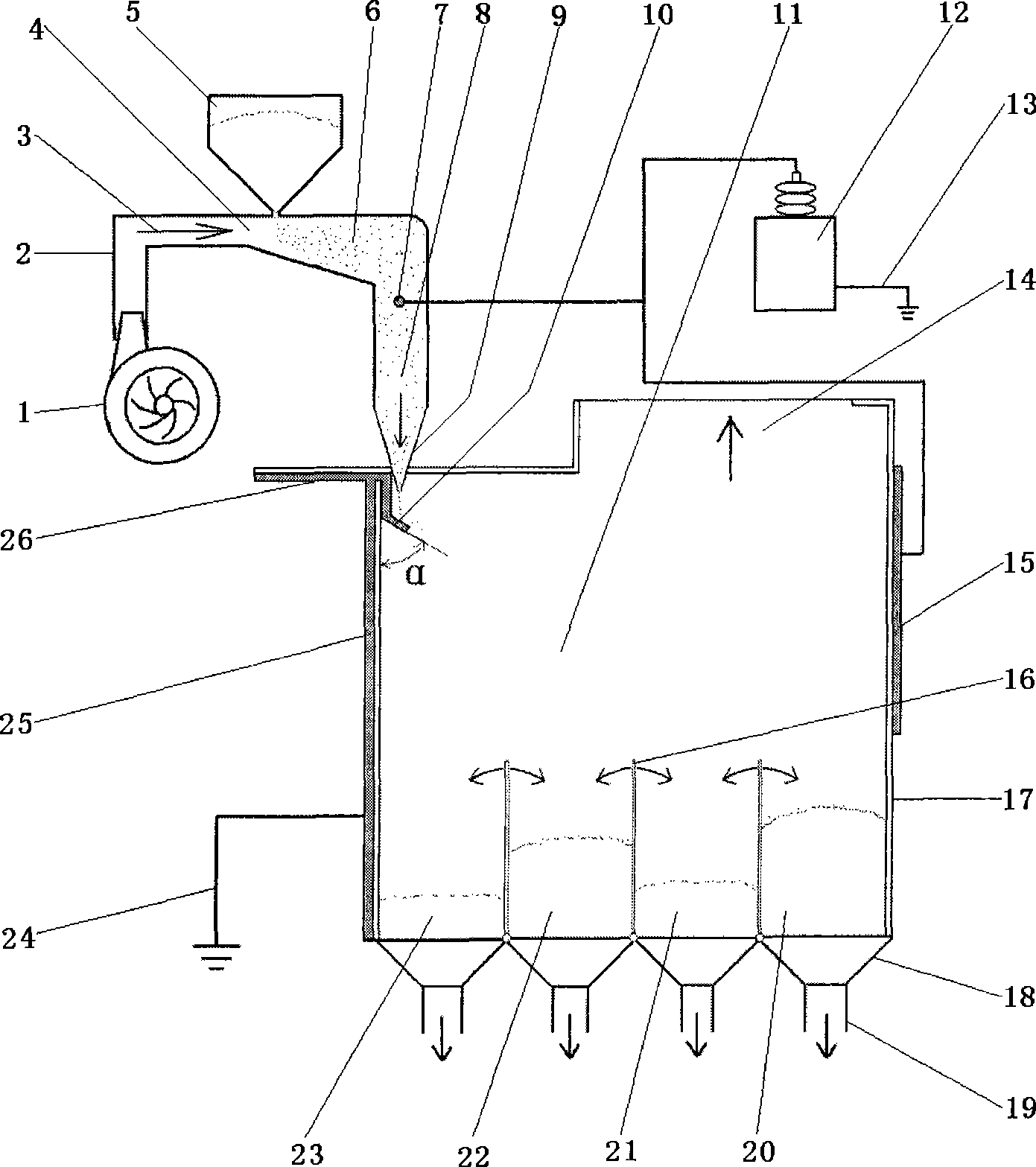

[0019] Embodiment 1: as figure 1 As shown, embodiment 1 uses a horizontal electric field to complete the sorting by falling by its own weight after spraying. The rutile concentrate produced by the rutile mine in Shangnan County, Shaanxi Province is sorted and purified by the present invention, and is sorted according to the mixed particle size of the original particle size components, and the grade T i o 2 86.31%, concentrate grade T i o 2 88.45%, good indicators of recovery rate 81.91%. In Example 1, although the concentrate grade is not greatly improved, the tailings have high impurities, less ore loss and high concentrate recovery. If you want to improve the concentrate grade, you can reuse embodiment 1 or refer to embodiment 2.

Embodiment 2

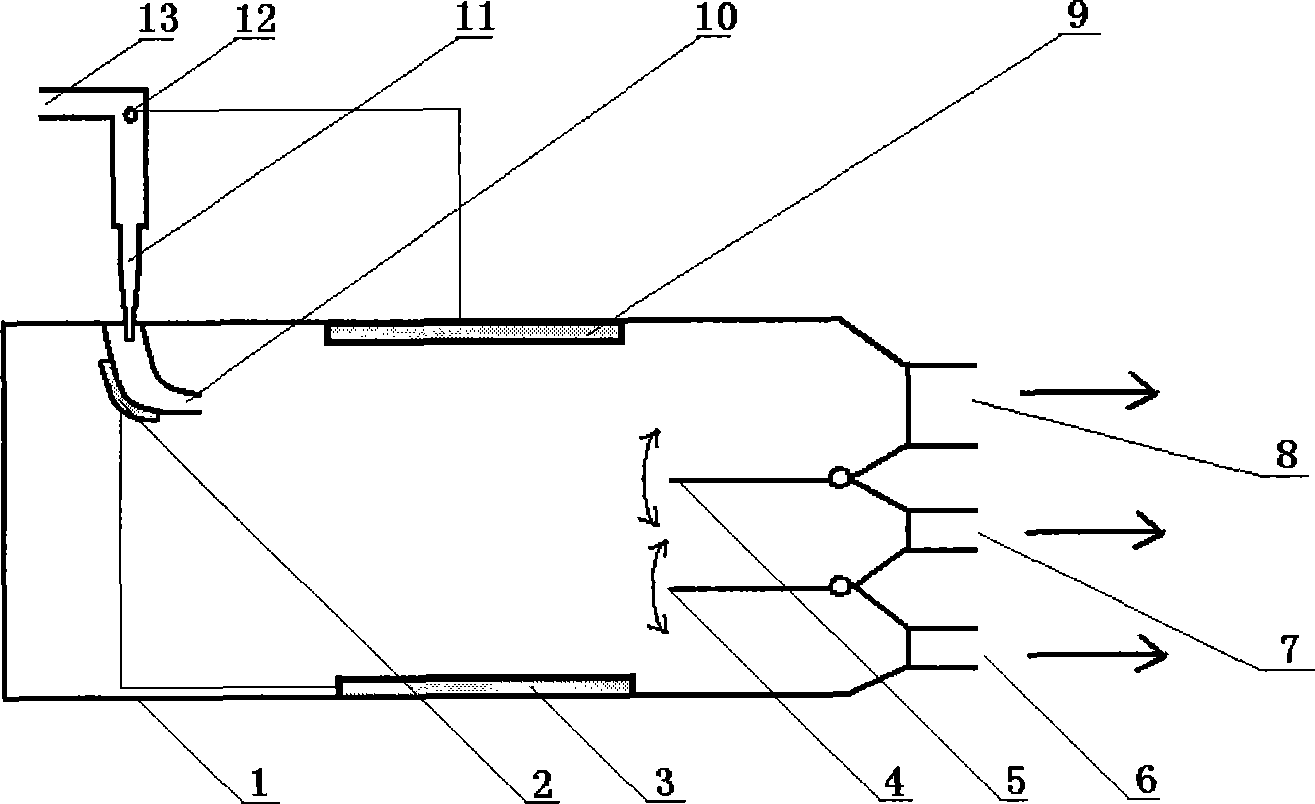

[0020] Embodiment 2: as figure 2 As shown, embodiment 2 uses vertical electric field after spraying to complete sorting by using spray inertia. The material enters from the feeding port 13, and after being negatively charged in the corona chamber, it is sprayed by the discharge nozzle 11 to the positive electrode 2 of the discharge plate for discharge, so as to achieve the effect that the conductor particles are completely discharged rather than the conductor particles are basically not discharged, and then sorted The nozzle 10 sprays horizontally into the sorting chamber 1, and the sorting is completed in the vertical electric field formed by the positive pole 3 of the sorting electrode and the negative pole 9 of the sorting pole. Although the recovery rate of concentrate ore in embodiment 2 has decreased, the grade of concentrate ore can be greatly improved, which is suitable for the production of high-grade concentrate ore. To improve the recovery rate of concentrate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com