Plasticiser sewage treatment technique

A technology for sewage treatment and plasticizer, which is applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. Achieve the effect of small process area, low operating cost, and reduced impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

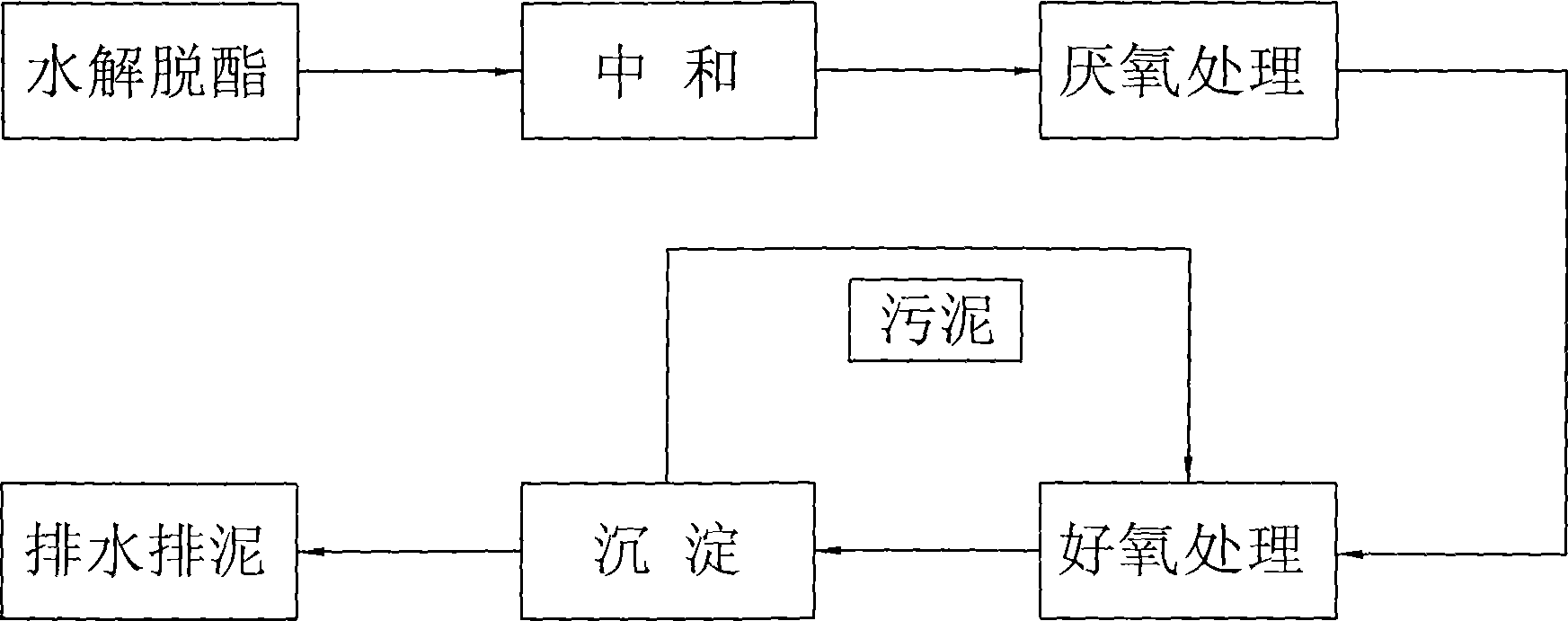

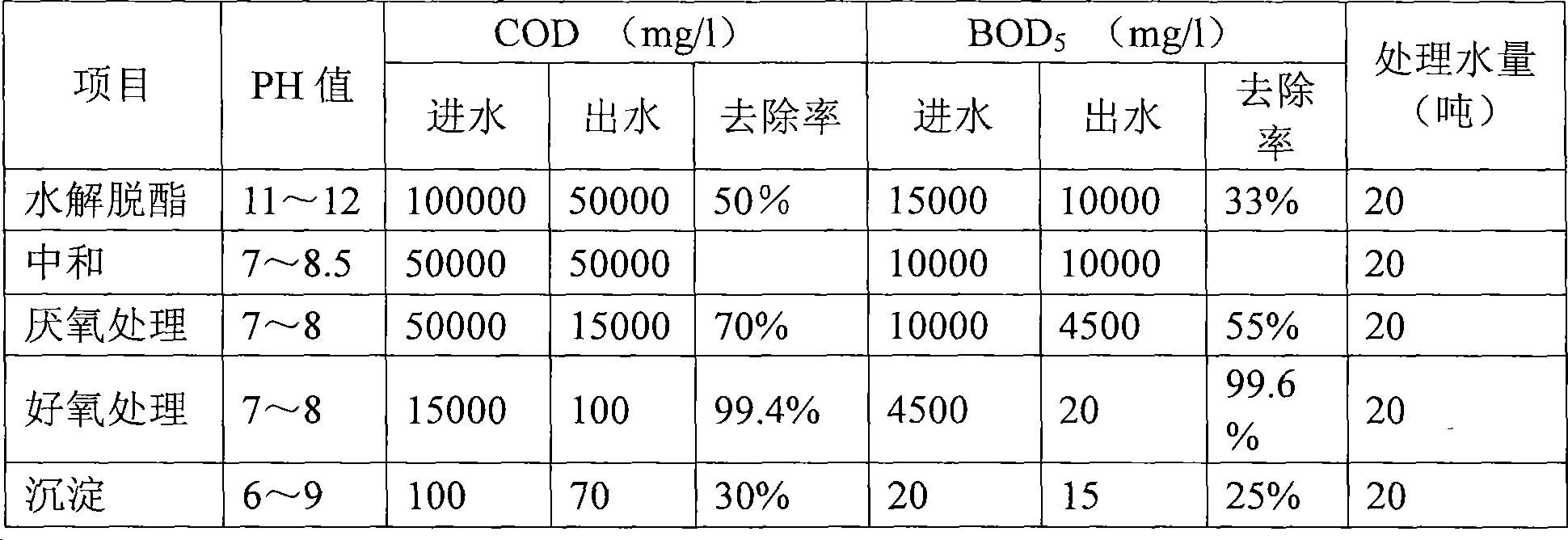

[0020] Such as figure 1 As shown, the sewage shall be treated in the following order:

[0021] (1) Hydrolysis and deesterification: Heat the wastewater to boiling, adjust the pH to about 11, hydrolyze for 2 hours, and heat the wastewater to boiling under alkaline conditions in the hydrolysis degreasing pool to make the esters hydrolyze; Lime, which allows benzene rings to react with calcium to form precipitates that can be removed from sewage; the alkali can be caustic soda, lime or other strong alkalis, and heating is generally done with steam;

[0022] (2) Neutralization: Add acid to the sewage in the neutralization tank to adjust the PH value of the wastewater to neutral, which is convenient for the next step of biochemical treatment; the acid can be sulfuric acid, hydrochloric acid or other acidic substances;

[0023] (3) Anaerobic treatment: Under anaerobic conditions, through the action of anaerobic bacteria, the refractory cyclic substances are opened, and the organic ...

Embodiment 2

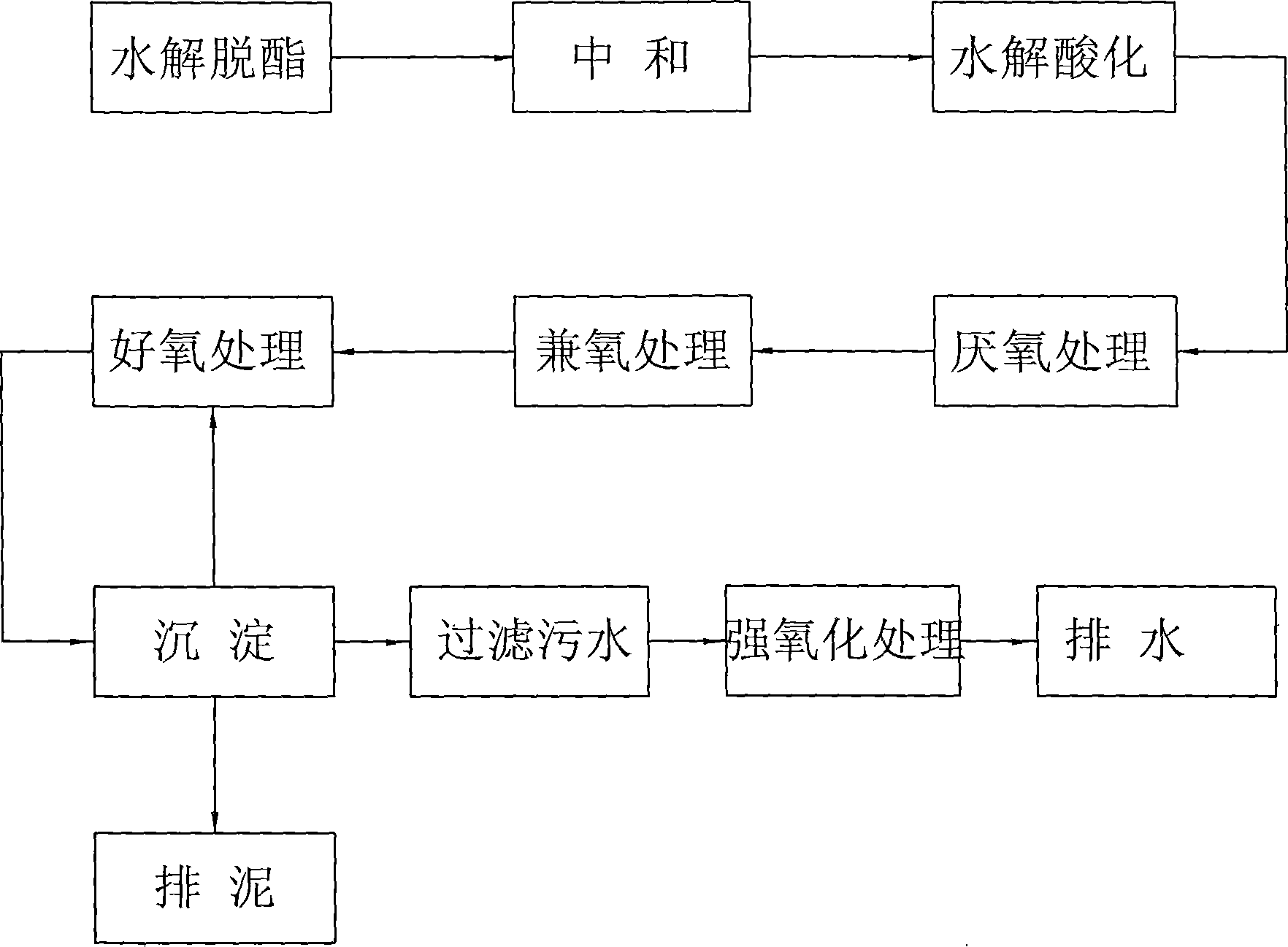

[0029] Such as figure 2 As shown, the sewage shall be treated in the following order:

[0030] (1) Hydrolysis and deesterification: Heat the wastewater to boiling, adjust the pH to about 11, hydrolyze for 2 hours, and heat the wastewater to boiling under alkaline conditions in the hydrolysis degreasing pool to make the esters hydrolyze; Lime, which allows benzene rings to react with calcium to form precipitates that can be removed from sewage; the alkali can be caustic soda, lime or other strong alkalis, and heating is generally done with steam;

[0031] (2) Neutralization: Add acid to the sewage in the neutralization tank to adjust the PH value of the wastewater to neutral, which is convenient for the next step of biochemical treatment; the acid can be sulfuric acid, hydrochloric acid or other acidic substances;

[0032] (3) The sewage is hydrolyzed and acidified between the neutralization and the anaerobic treatment, and the wastewater is pre-acidified, which can greatly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com