Process for comprensive treating waste water of paper making by grass pulp

A technology for comprehensive treatment of papermaking wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of straw pulp and papermaking wastewater polluting the environment, and achieve reduction of pollution load, Reduction of processing cost, effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

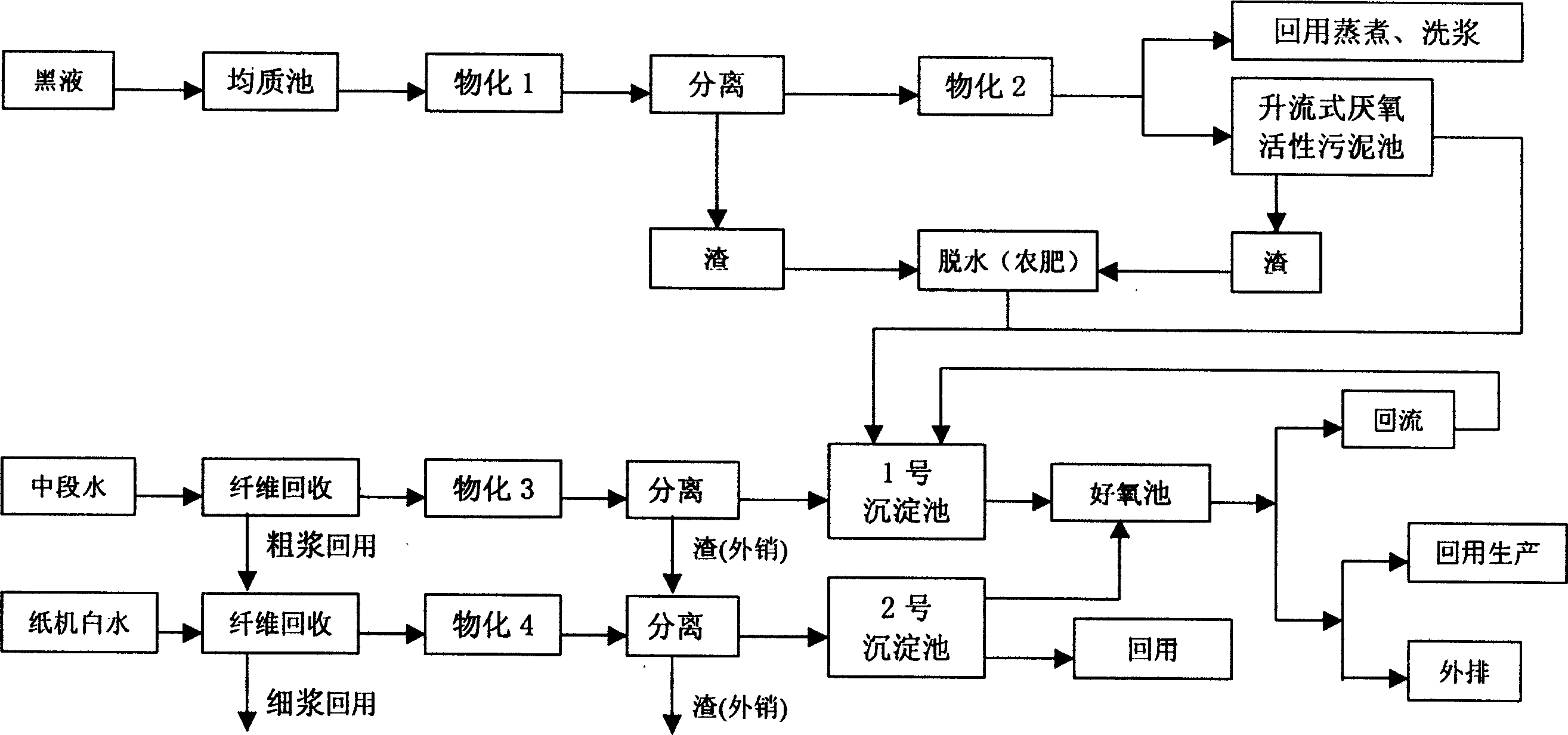

Image

Examples

Embodiment 1

[0076] 1. Process of black liquor treatment plan:

[0077] 1. Circulate the black liquor produced by presoaking low-temperature rapid cooking in the homogenization tank for 24 hours, so that the temperature is reduced to 35°C and the pH is about 12.

[0078] 2. Pump the thick black liquor in the homogeneous tank to the pipeline, add No. 1 agent, add No. 5 agent at an interval of about 10 seconds, and then add No. 2 agent at an interval of 10 seconds, enter the reaction tank, and then add No. 3 agent After 30 seconds, add agent No. 4 and adjust the pH to 14 for cooking.

[0079] 3. Pump the dilute black liquor in the homogeneous tank to the pipeline for treatment according to the agent and interval time for treating thick black liquor. At this time, the pH of the clear liquid reaches 4-5, and it is reused for pulp washing. After washing the pulp, adjust the pH to 6.5-8.5 and use a pump to enter the upflow anaerobic activated sludge tank. After full anaerobic digestion, it ente...

Embodiment 2

[0098] 1. Process of black liquor treatment plan:

[0099] 1. Circulate the black liquor produced by presoaking low-temperature rapid cooking in the homogenization tank for 30 hours, so that the temperature is reduced to 35°C and the pH is about 10.

[0100] 2. Pump the thick black liquor in the homogeneous tank to the pipeline, add No. 1 agent, add No. 5 agent at an interval of about 10 seconds, and then add No. 2 agent at an interval of 10 seconds, enter the reaction tank, and then add No. 3 agent After 30 seconds, add agent No. 4 and adjust the pH to 12 for cooking.

[0101] 3. The dilute black liquor in the homogeneous tank is pumped to the pipeline for treatment according to the agent and interval time for treating thick black liquor. At this time, the pH of the clear liquid reaches 4-5, and it is reused for pulp washing. After washing the pulp, adjust the pH to 6.5-8.5 and use a pump to enter the upflow anaerobic activated sludge tank. After full anaerobic digestion, it e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com