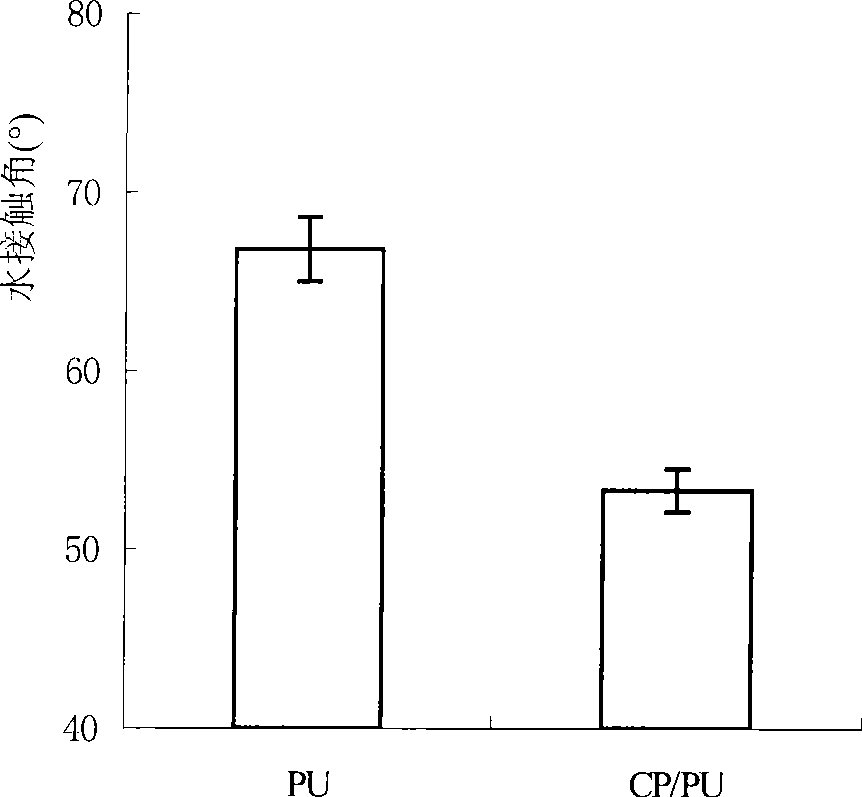

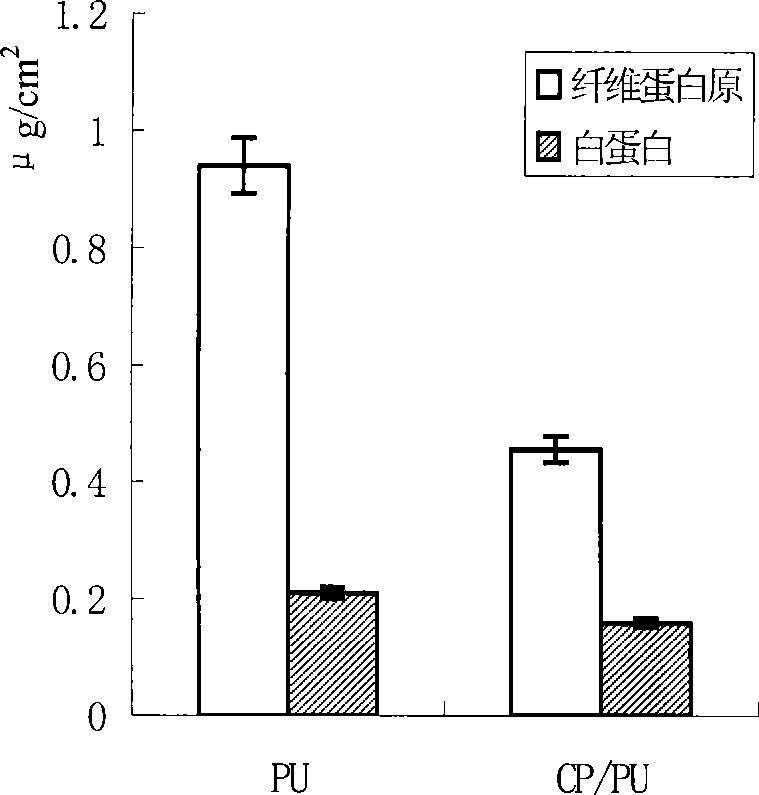

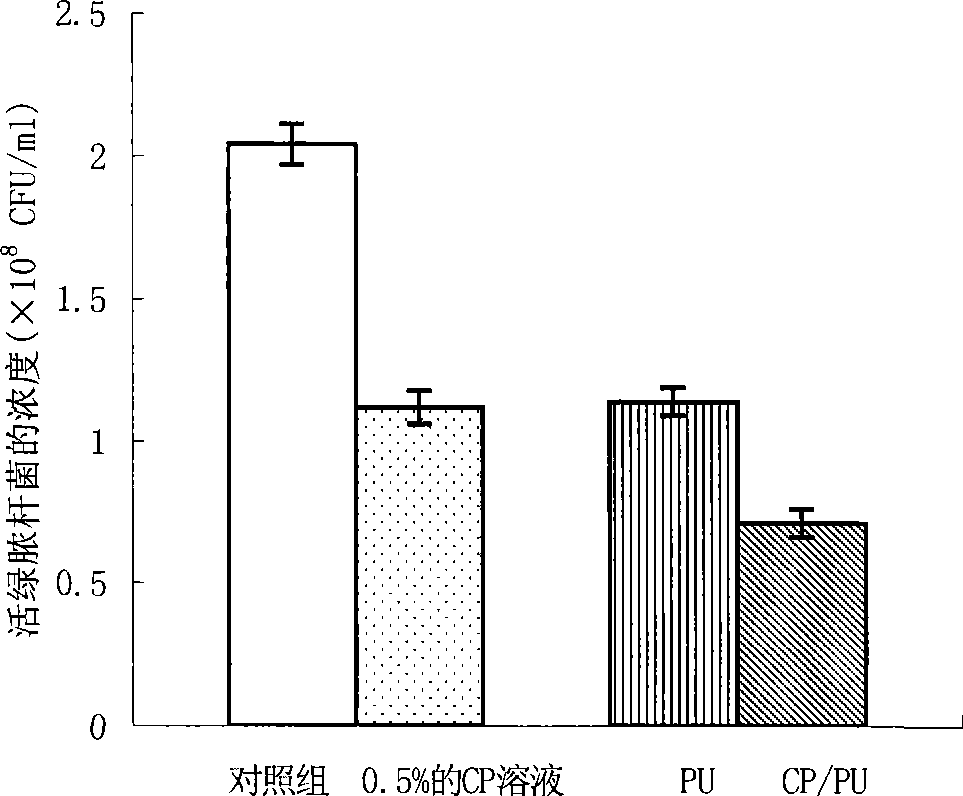

Polyurethane material with anti-protein adsorption and antibacterial functions

A polyurethane material and anti-protein adsorption technology, applied in the fields of biomedical materials and polymer chemistry, can solve problems such as necrosis and repeated infection of tissue, and achieve the effects of easy control, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] (1) Preparation of CP:

[0021] On an ice bath, first disperse 0.6-1.2g of Poria cocos sclerotia polysaccharide in 10-20mL of a mixture I consisting of 20% NaOH and 25-50mL of isopropanol by mass percentage, and stir for 3-4 hours to form a uniform suspension for reaction system. Then 5.25-10.50 g of chloroacetic acid was dissolved in 25-50 mL of isopropanol, and mixed with another 10-20 mL of 20% NaOH in a mass ratio to form a mixed solution II. Slowly add half of the above mixed solution II into the reaction system dropwise, stir and react at room temperature for 3-4 hours, then raise the temperature of the reaction solution to 60-65°C and continue stirring for 30-40 minutes. Then the other half of the mixture II was slowly added dropwise, and the reaction was continued for 40-60 min at 60-65°C. After stopping the reaction, cool to room temperature, and then adjust the pH value of the reaction solution to 6 with 0.3-0.5M HCl. The above reaction solution was dialyze...

Embodiment 1

[0033] On an ice bath, first disperse 0.6 g of Sclerotinia polysaccharide in 10 mL of a mixture I consisting of 20% NaOH and 25 mL of isopropanol, and stir for 3 hours to form a uniform suspension reaction system. Then 5.25 g of chloroacetic acid was dissolved in 25 mL of isopropanol, and mixed with another 10 mL of 20% NaOH in a mass ratio to form a mixed solution II. First half of the above mixed solution II was slowly added dropwise to the reaction system, stirred and reacted at room temperature for 3 hours, and then the reaction solution was heated to 60° C. and continued to stir for 40 minutes. Then the other half of the mixture II was slowly added dropwise, and the reaction was continued for 60 min at 60°C. After stopping the reaction, cool to room temperature, and then adjust the pH value of the reaction solution to 6 with 0.5M HCl. The above reaction solution was dialyzed with running water for 3 days and distilled water for 3 days, concentrated by rotary evaporation,...

Embodiment 2

[0036] On an ice bath, first disperse 1.2 g of Sclerotinia polysaccharide in 20 mL of a mixture I consisting of 20% NaOH and 50 mL of isopropanol by mass percentage, and stir for 4 hours to form a uniform suspension reaction system. Then 10.50 g of chloroacetic acid was dissolved in 50 mL of isopropanol, and mixed with another 20 mL of 20% NaOH in a mass ratio to form a mixed solution II. Slowly add half of the above mixed solution II into the reaction system dropwise, stir the reaction at room temperature for 3 hours, then raise the temperature of the reaction solution to 65° C. and continue stirring for 30 minutes. Then the other half of the mixture II was slowly added dropwise, and the reaction was continued for 40 min at 65°C. After stopping the reaction, cool to room temperature, and then adjust the pH value of the reaction solution to 6 with 0.3M HCl. The above reaction solution was dialyzed with running water for 4 days and distilled water for 3 days, concentrated by r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com