Pineapple leaf fiber biochemical degumming technique

A pineapple leaf fiber and biochemical technology is applied in the chemical post-treatment of fibers, fiber treatment, textiles and papermaking, etc., which can solve the problems of high energy consumption, large fiber damage, serious chemical pollution, etc. requirements, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

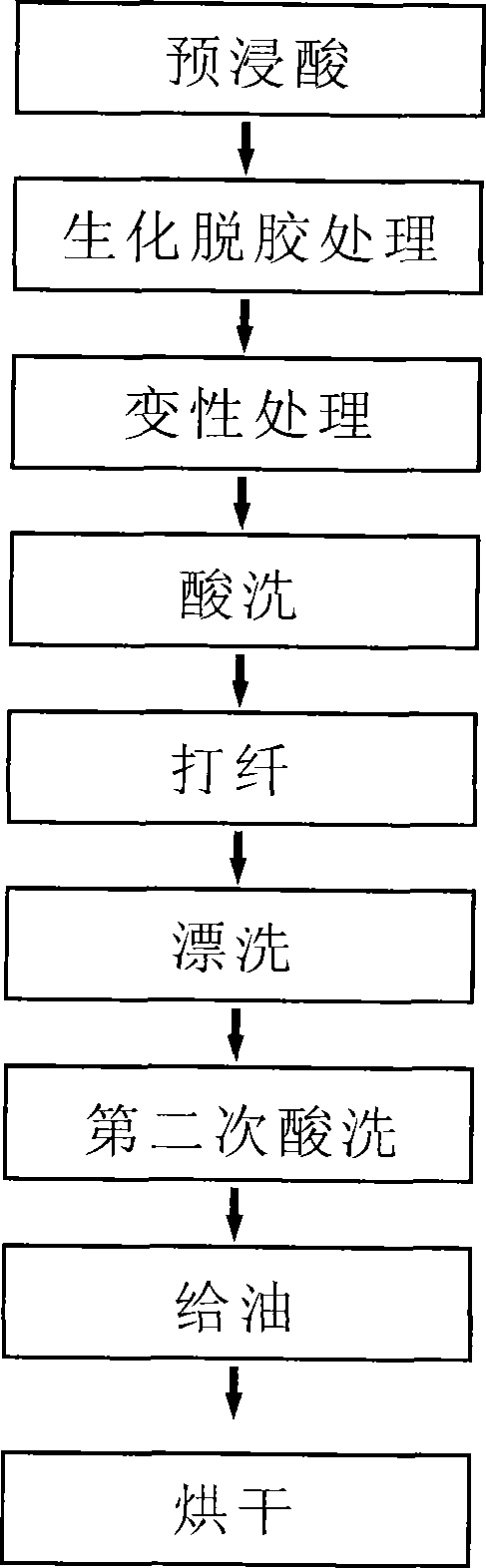

[0022] Such as figure 1 Shown, pineapple leaf fiber biochemical degumming process, it comprises the following steps:

[0023] (1) Pre-dipping acid: the fibrils are put into 16 times their weight containing H 2 SO 4 and chlorine dioxide activator solution, soak at room temperature for 40 minutes, take it out and wash it with water; in the solution, H 2 SO 4 The content is 1.6g / L, and the content of chlorine dioxide activator is 1.4g / L.

[0024] (2) Biochemical degumming treatment: put the fibrils into the treatment solution with an enzyme preparation concentration of 3g / L, the bath ratio is 1:16, the temperature is 45°C, and the treatment time is 12h, and the raw hemp is taken out.

[0025] (3) Denaturation treatment: the fibrils are put into a solution prepared by mixing 30% liquid caustic soda and soda ash with a concentration of 16 times of its weight, soaked at normal temperature for 20 minutes to take out the former hemp; in the described solution, the liquid caustic s...

Embodiment 2

[0034] Pineapple leaf fiber biochemical degumming process, it comprises the following steps:

[0035] (1) Pre-soaking acid: the fibrils are put into 15 times their weight containing H 2 SO 4 and chlorine dioxide activator solution, soak at room temperature for 40 minutes, take it out and wash it with water; in the solution, H 2 SO 4 The content is 1.4g / L, and the content of chlorine dioxide activator is 1.2g / L.

[0036] (2) Biochemical degumming treatment: put the fibrils into the treatment solution with an enzyme preparation concentration of 2.5g / L, the bath ratio is 1:15, the temperature is 40°C, and the treatment time is 12h, and the raw hemp is taken out.

[0037] (3) Denaturation treatment: the fibrils are put into a solution prepared by mixing 30% liquid caustic soda and soda ash with a concentration of 15 times of its weight, soaked at room temperature for 20 minutes to take out the former hemp; in the described solution, the liquid caustic soda The content is 115g / ...

Embodiment 3

[0046] Pineapple leaf fiber biochemical degumming process, it comprises the following steps:

[0047] (1) Pre-dipping acid: the fibrils are put into 17 times their weight containing H 2 SO 4 and chlorine dioxide activator solution, soak at room temperature for 40 minutes, take it out and wash it with water; in the solution, H 2 SO 4 The content is 1.8g / L, and the content of chlorine dioxide activator is 1.6g / L.

[0048] (2) Biochemical degumming treatment: Put the fibrils into the treatment solution with an enzyme preparation concentration of 3.5g / L, the bath ratio is 1:17, the temperature is 50°C, and the treatment time is 12h, and the raw hemp is taken out.

[0049] (3) Denaturation treatment: the fibrils are put into a solution prepared by mixing 30% liquid caustic soda and soda ash with a concentration of 17 times of its weight, soaked at room temperature for 20 minutes to take out the former hemp; in the described solution, the liquid caustic soda The content is 125g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com