High-energy plasma igniter of gas turbine

A plasma point and gas turbine technology, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve problems such as life reduction, ignition energy limitation, and electrode ablation intensification, so as to improve cooling effect, prolong electrode life, and fully cool Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

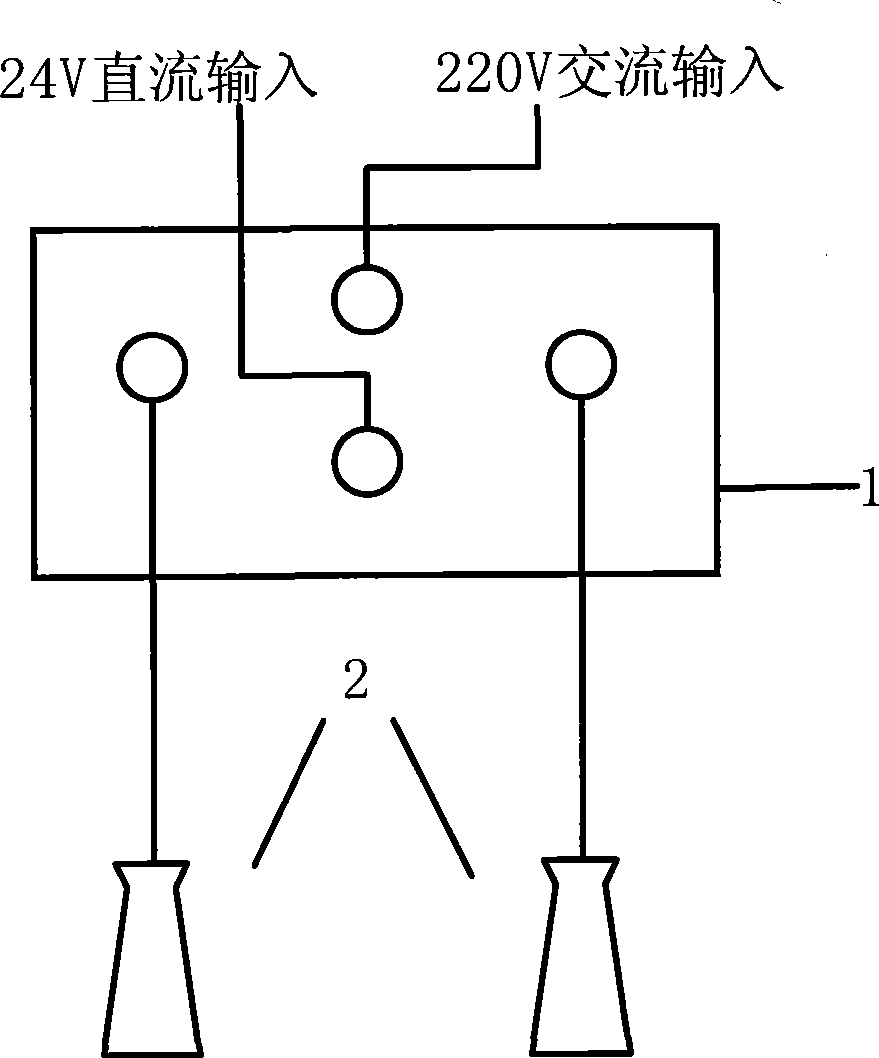

[0019] figure 1 It is the connection schematic diagram of the gas turbine high-energy plasma igniter of the present invention. The gas turbine high-energy plasma igniter of the present invention mainly includes: an ignition exciter 1, a matching plasma generator 2 and a high-voltage ignition cable. The number of ignition sources can be determined according to factors such as gas turbine power and fuel. The number of ignition sources is the number of plasma generators 2 . According to the number of 2 plasma generators, the ignition exciter 1 module can be expanded. For example, if one ignition exciter 1 is designed with 2 outputs, if 4 ignition sources are required, two ignition exciters 1 and 4 sets of plasma generators are equipped. 2 and high voltage ignition cable.

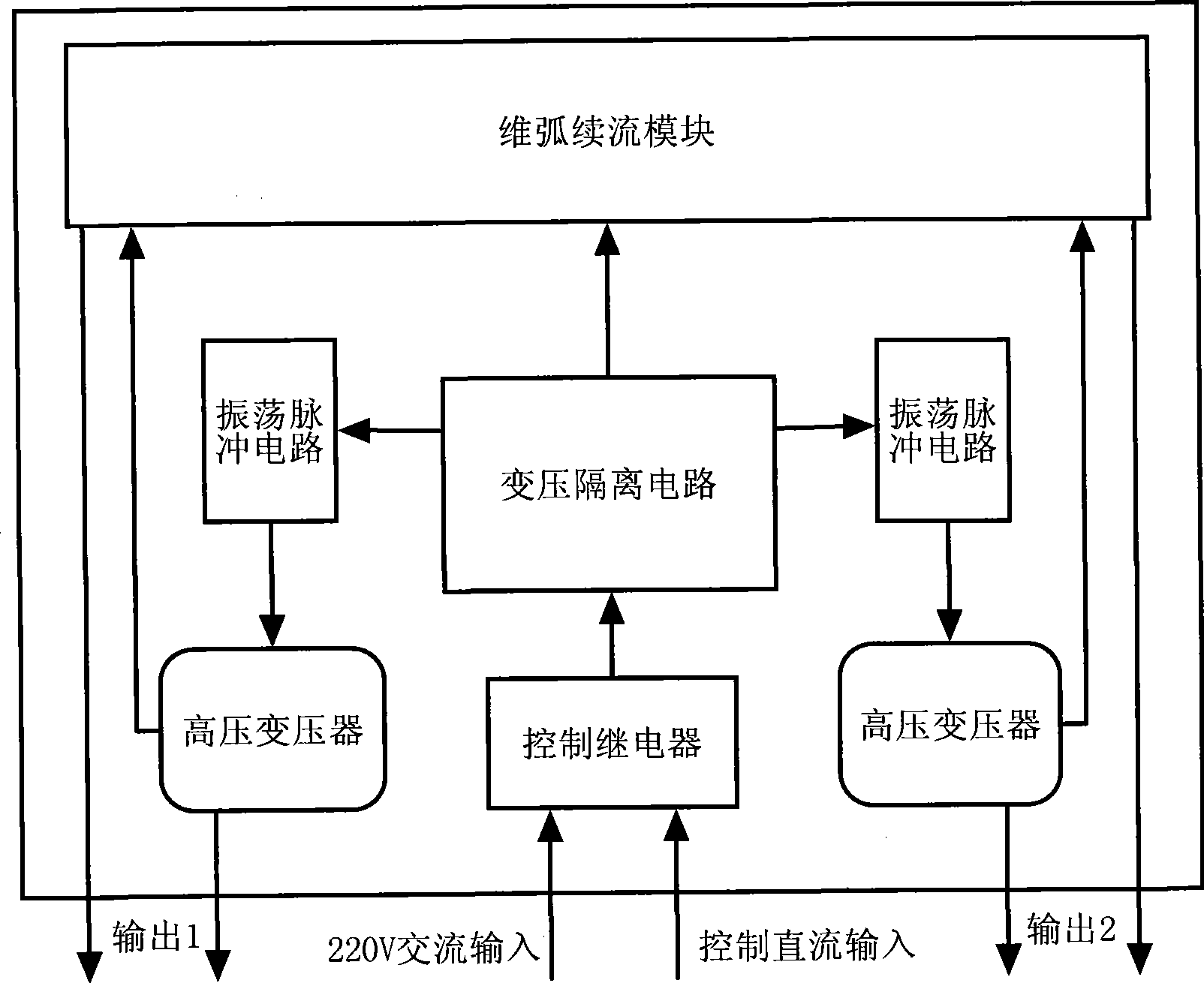

[0020] figure 2 It is a schematic diagram of the internal structure module of the ignitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com