Photometry apparatus of luminophor

A light-emitting element and light-splitting technology, which can be used in measuring devices, photometry, optical instrument testing, etc., can solve the problems of lack of reliability in precision, inability to correctly determine the amount of light, and inability to detect intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

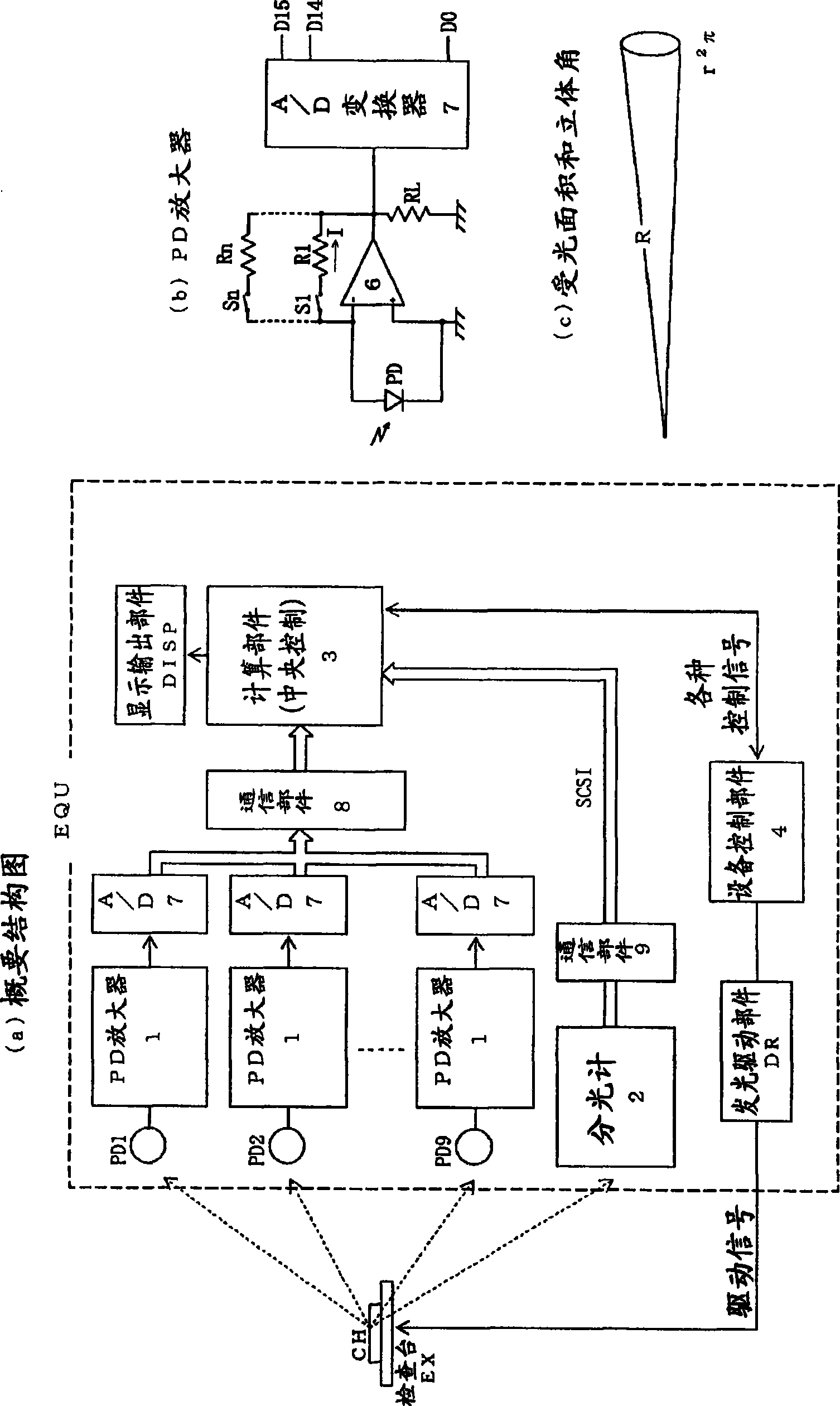

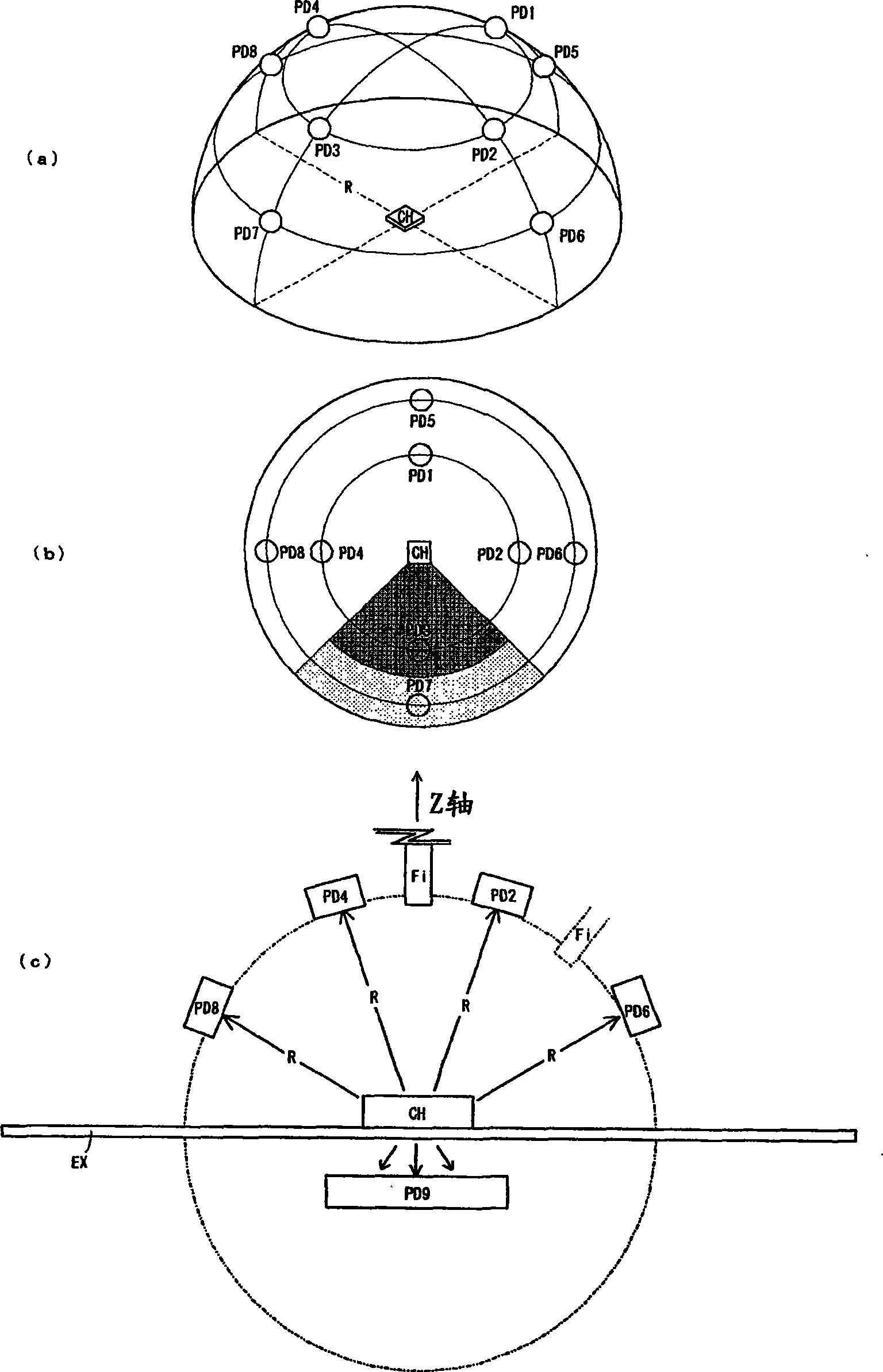

[0032] Hereinafter, the present invention will be described in more detail based on examples. figure 1 (a) is a circuit block diagram showing a schematic configuration of the photometry device EQU of the embodiment. In this photometry device EQU, a light-emitting element chip CH to be inspected is placed on an inspection table EX made of translucent glass, and is driven to turn on. Then, through the light metering device EQU, automatically calculate its luminous characteristics and output.

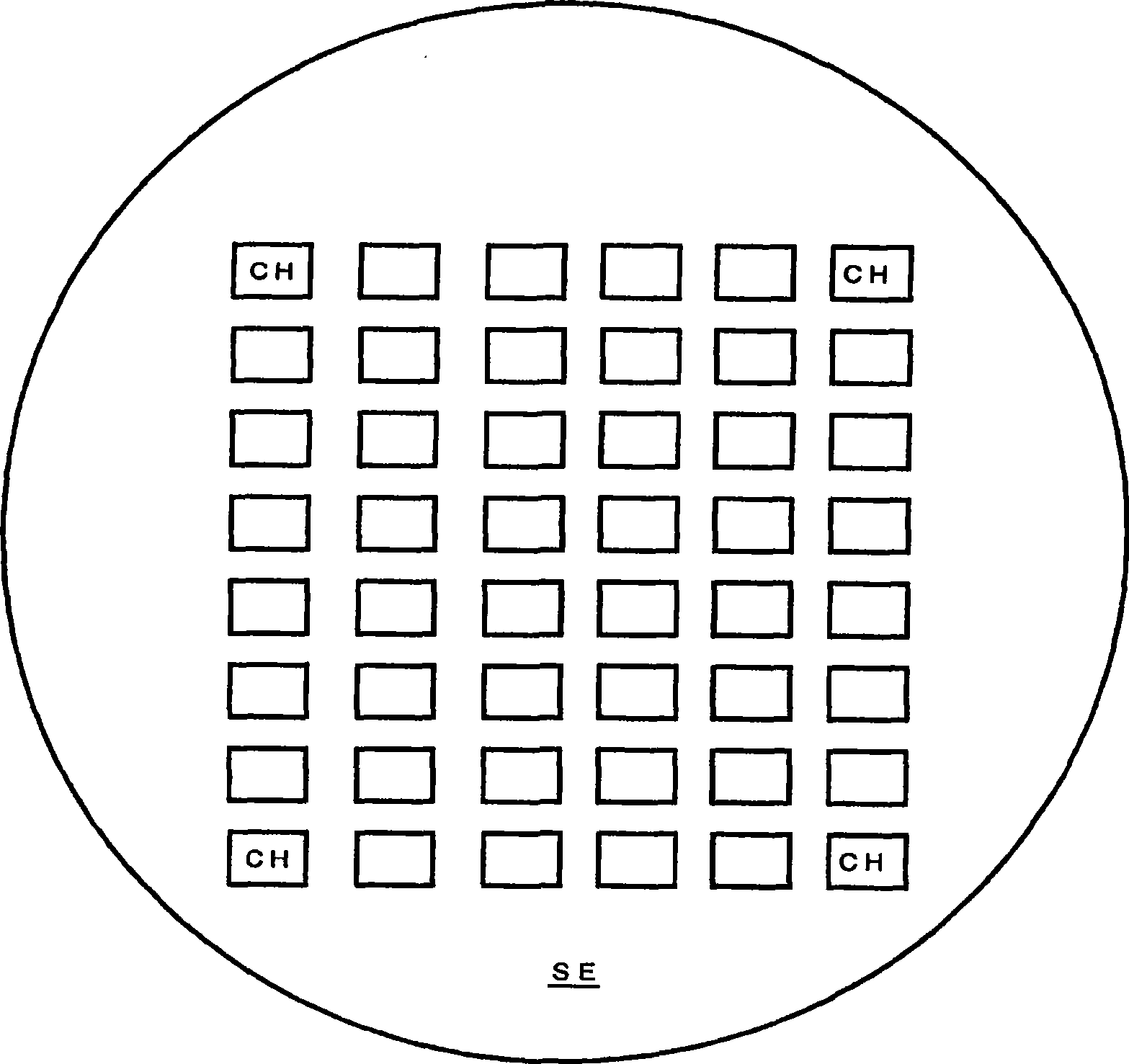

[0033] The light emitting element chip CH is, for example, a semiconductor chip constituting a light emitting diode. In addition, the plurality of light-emitting element chips CH...CH cut out by cutting the semiconductor wafer are held on the adhesive sheet SE and stand by ( image 3 ). In addition, a robot hand takes out the light-emitting element chips CH in the standby state one by one, and places them on the inspection table EX.

[0034] The light-emitting element chip has a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com