Method for detecting high-strength steel fillet welding joint performance

A high-strength, fillet weld technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problem of no detection method, prevent the generation and expansion of micro-cracks, avoid multi-layer multi-pass welding, applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

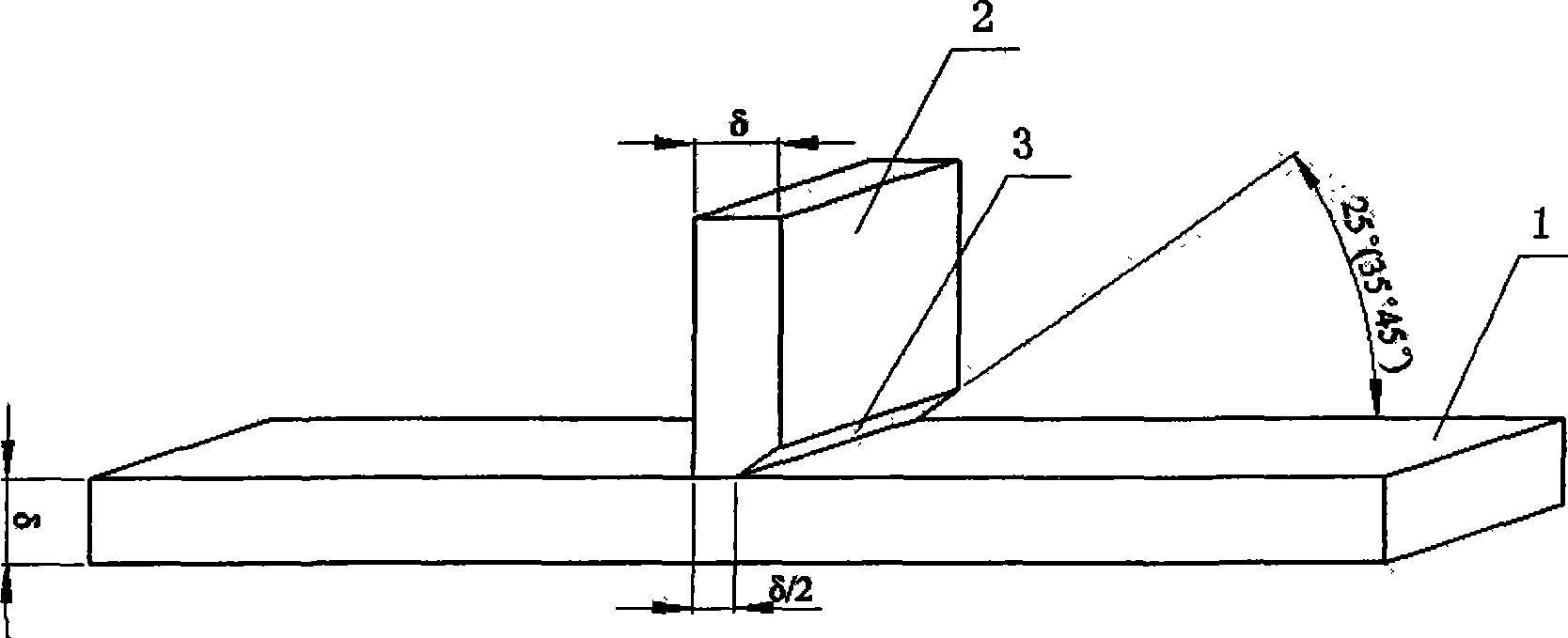

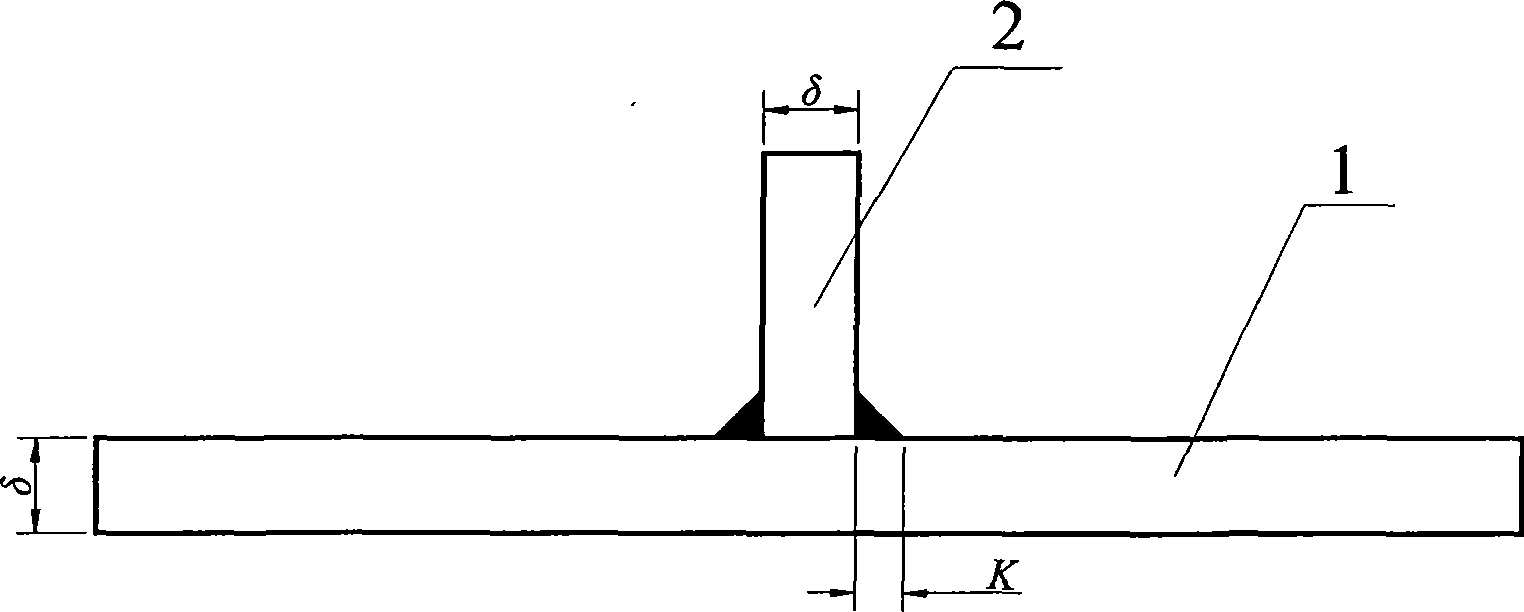

[0029] Base material: such as figure 1 As shown, Q550 low-alloy quenched and tempered high-strength steel with a thickness of 20mm is welded to a vertical plate 2 with a height of 45mm on three test plates 1 of 300mm×300mm to form a T-shaped structure. A single V-shaped groove 3 is made at the corner joint between the vertical plate 2 and the test plate 1, and the angles of the three grooves 3 are 25°, 35°, and 45° respectively.

[0030] Welding material: 600MPa gas shielded welding solid wire with a diameter of 1.2mm.

[0031] Welding method: Ar+CO 2 Mixed gas shielded welding, in which Ar and CO 2 The volume percentage is 80%:20%.

[0032] Welding process parameters: welding voltage 28V~29V, welding current 240V~270A, welding speed 0.4cm / s~0.5cm / s, welding heat input 13.4kJ / cm~19.6kJ / cm, shielding gas flow 15~20L / min; Number of welding layers: 3 layers, using multi-layer multi-pass welding; Number of welding passes: 8 passes when the groove angle is 25°, 16 passes when t...

Embodiment 2

[0037] Base material: such as figure 1 As shown, the HQ80 low-alloy high-strength steel with a thickness of 30mm, the vertical plates 2 of the three T-shaped joints are respectively opened with 25°, 35°, and 45° single V-shaped grooves 3, the size of the test plate 1 is 300mm×300mm, the vertical plate 2 The size is 300mm×60mm.

[0038] Welding material: 800MPa gas shielded welding solid wire with a diameter of 1.2mm.

[0039] Welding method: Ar+CO 2 Mixed gas shielded welding, in which Ar and CO 2 The volume percentage is 80%:20%.

[0040]Welding process parameters: welding voltage 27V~28V, welding current 230A~260A, welding speed 0.5cm / s, welding heat input 12.4kJ / cm~14.6kJ / cm, shielding gas flow 16~18L / min, number of welding layers: 3 Layer, using multi-layer multi-pass welding. Number of weld passes: 10 passes when the groove angle is 25°, 21 passes when the groove angle is 35°, and 35 passes when the groove angle is 45°.

[0041] Key points of welding technology: Wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com