Method of testing vehicle electric appliance system reliability

A technology of automotive electrical appliances and test methods, applied in vehicle testing, machine/structural component testing, instruments, etc., can solve the problems of high test cost, long cycle, unfavorable design improvement and product quality control, etc., to ensure reliability. and consistency, workload reduction, retrospective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The automotive electrical system reliability test method in the present embodiment is:

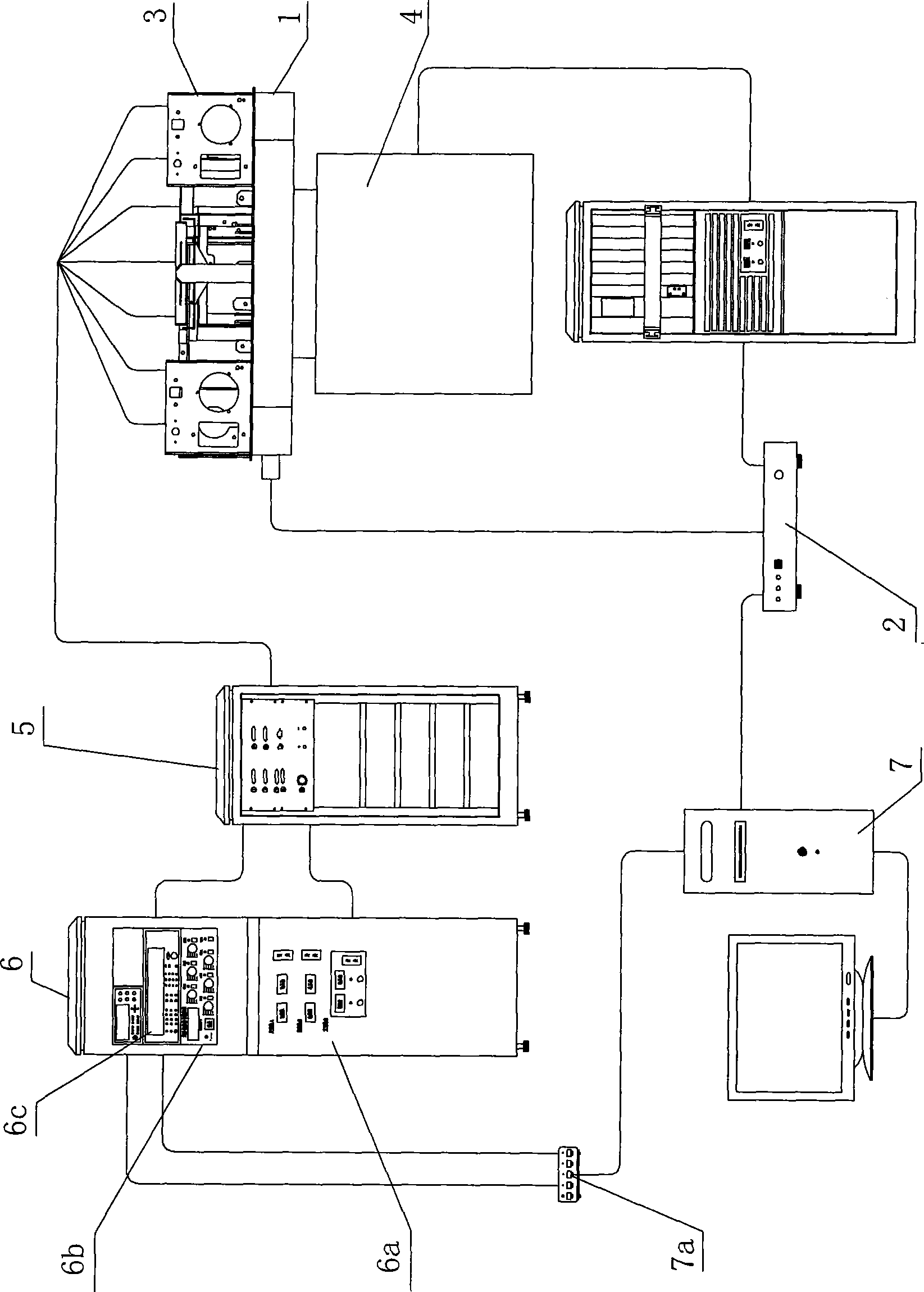

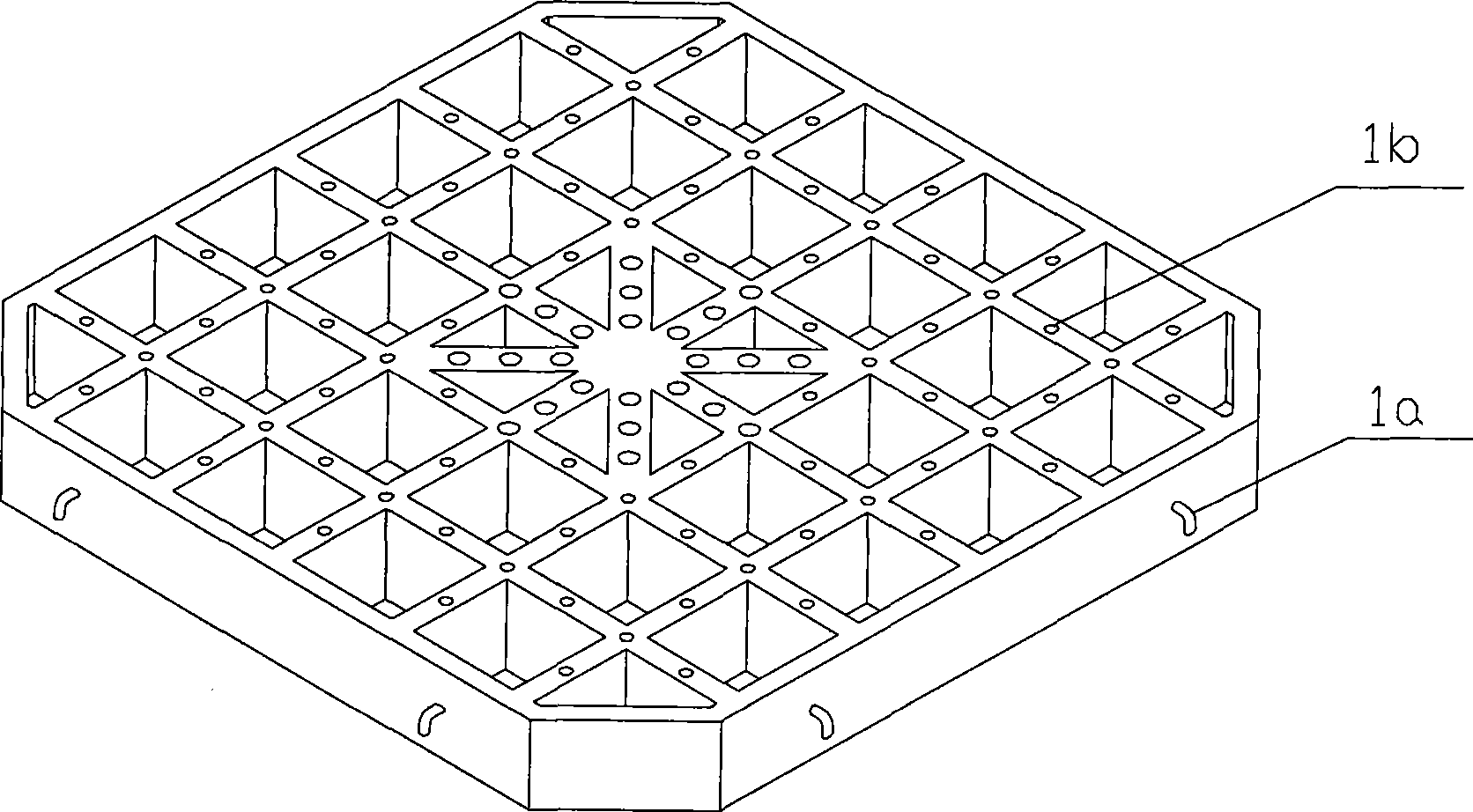

[0030] see figure 2 On the test bench 1, connect the automotive electrical appliances and the wiring harness used by the original car according to the actual use state, and connect the test power supply 6a and the synchronous output signal of the signal simulator 6b through the test auxiliary cable in the cable cabinet 5 to form a synchronous output signal that can make the car The electric system of the automobile under test whose electrical appliances work in the state of the real vehicle on the test bench 1, and this system is used as the test object;

[0031] figure 2 As shown, the power supply system used to provide the test power supply 6a is built in the lower layer of the instrument cabinet 6, providing 220V AC power supply for the system instruments, and simultaneously providing 0-30V continuously adjustable DC power output to apply electrical stress to the test object. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com