Technological method of fine boring large-sized diesel engine cylinder porous series

A process method and cylinder block technology, applied in the direction of boring/drilling, boring bars, manufacturing tools, etc., can solve the problems of high size, shape and position accuracy, high surface roughness requirements, high cost, etc., and achieve high processing accuracy , meet the requirements of high-precision technology, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

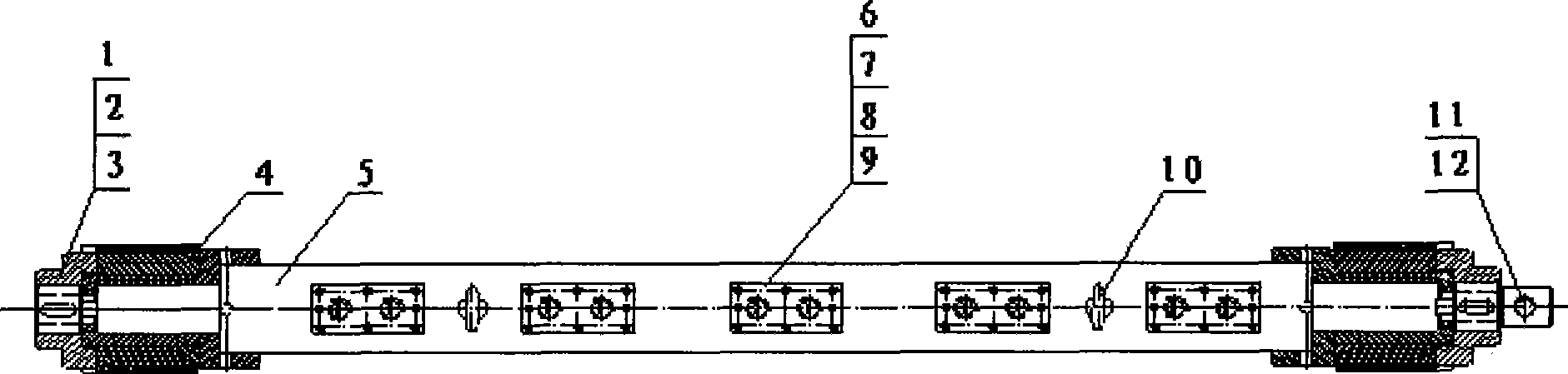

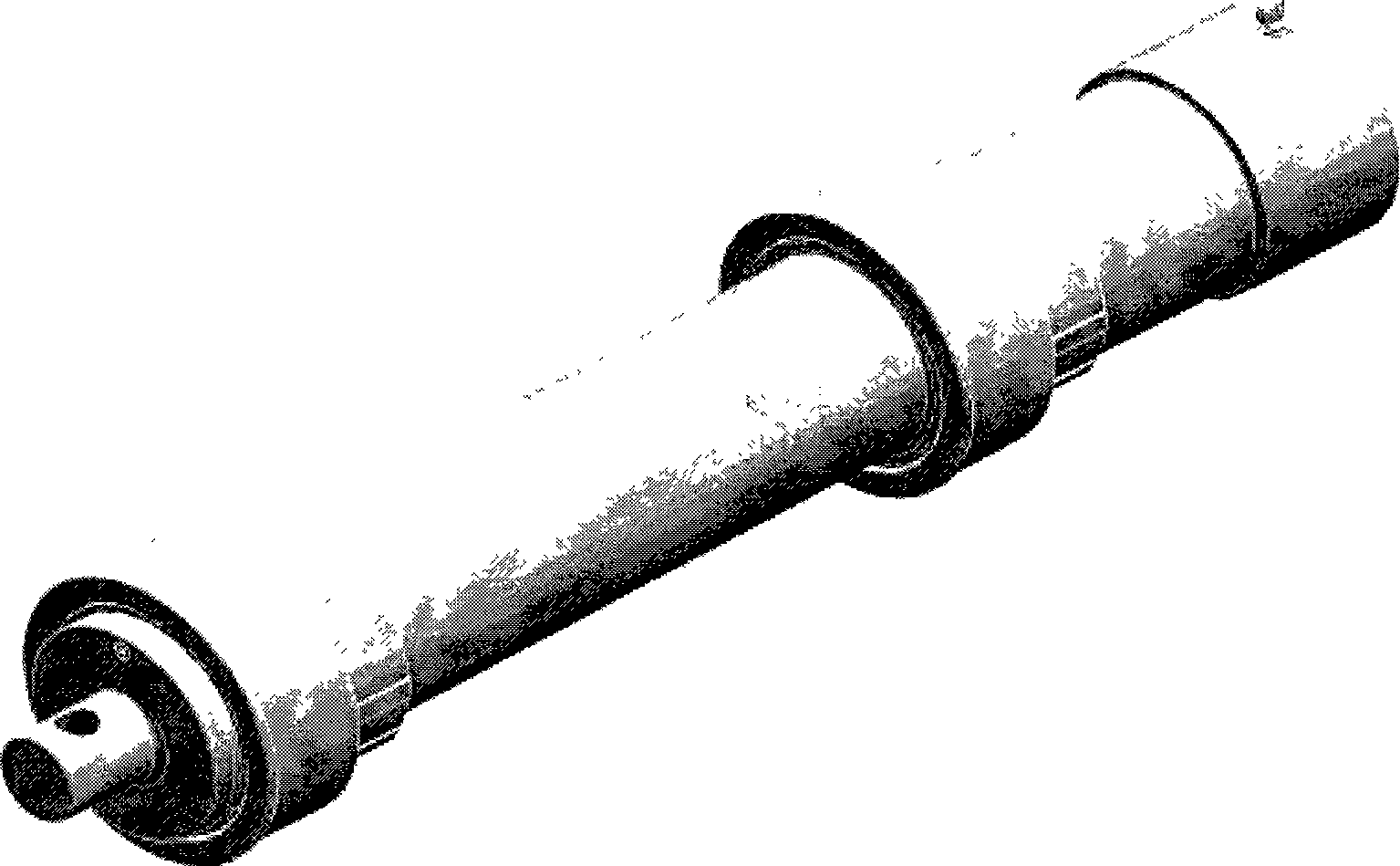

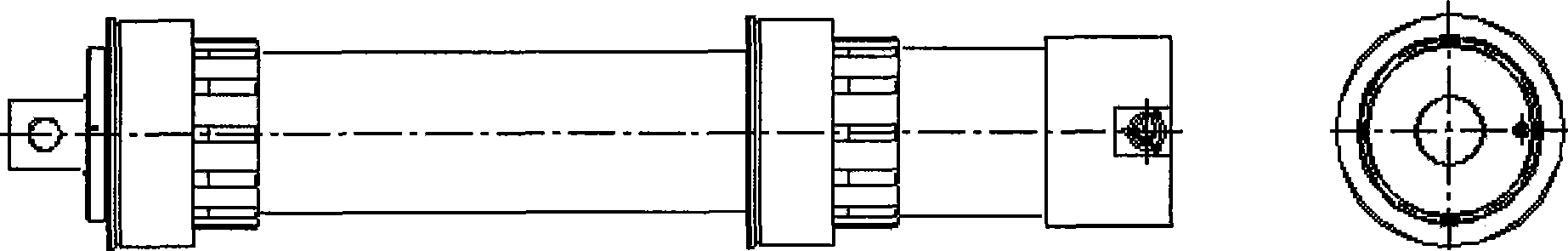

[0020] The specific implementation process will be described below by taking the method of finishing the main shaft hole of the cylinder block of a large diesel engine as an example.

[0021] (1) Processing on a horizontal boring machine

[0022] Taking the machining of the main shaft hole of the cylinder block of a 6-cylinder heavy-duty diesel engine (power exceeding 700KW) as an example, the first and seventh gear main shaft holes of the cylinder block are roughly and finely machined to the size and accuracy on a horizontal boring machine using conventional methods, and then disassembled. Remove the bearing caps of the 1st and 7th gear spindle holes, install the guide sleeve I4 on the 1st and 7th gear spindle holes, install the 1st and 7th gear main bearing caps according to the assembly requirements of the cylinder block-crankshaft cover, and then install the floating Boring bar (remove the ring screw 10), install and adjust the boring tool according to the rough machining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com