Annular region smelting furnace

A ring-shaped area and melting furnace technology, applied in self-area melting methods, furnaces, crucible furnaces, etc., can solve the problems that the purification results cannot be close to the limit distribution, low yield and output, etc., so as to improve the purification efficiency and product output, Produce efficient, compact and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

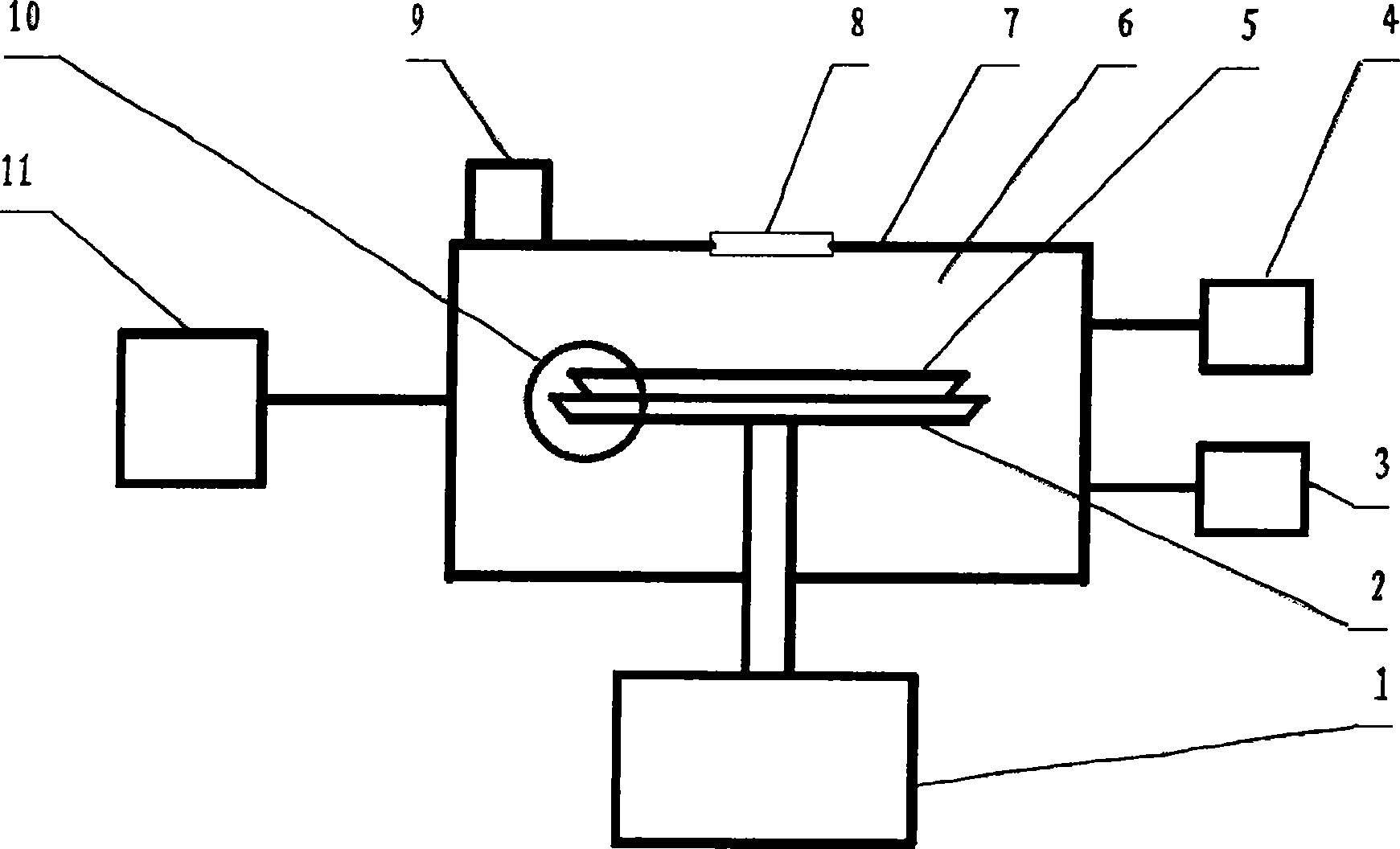

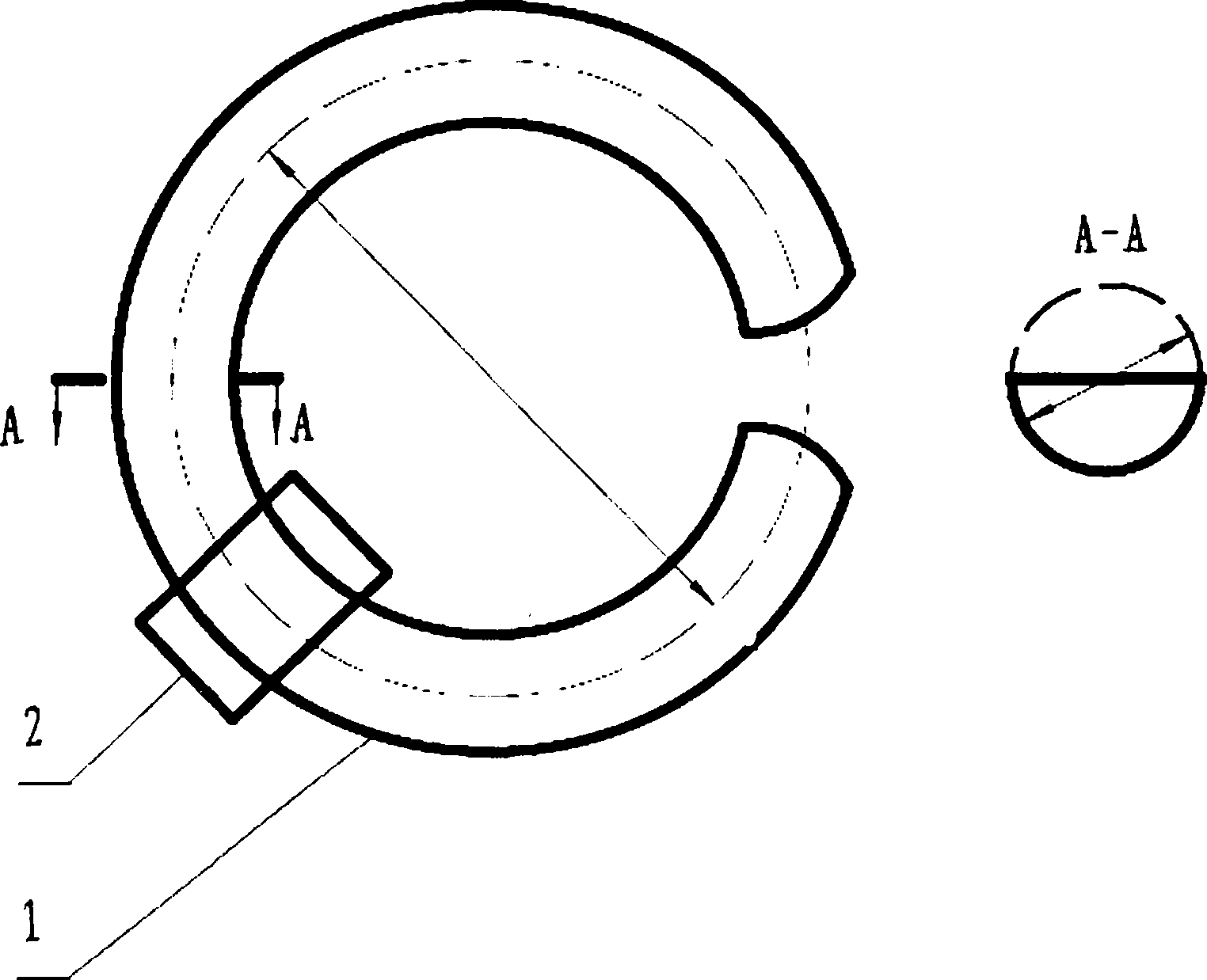

[0022] Such as figure 1 Shown is a schematic diagram of the structure of the annular zone smelting furnace of the present invention. The ring-shaped area melting furnace includes: furnace cover 7, vacuum chamber 6, quartz ring-shaped area melting boat 5, heating coil 10, high-frequency power supply 11, vacuum system 4, protective gas input device 3, supporting steel ring 2, temperature measurement With temperature control system 9 and rotating drive system 1. The quartz ring zone melting boat 5 has a ring structure and is made of quartz or graphite materials. It is placed in a support steel ring 2 with a similar appearance. The rotating drive system 1 includes a drive motor, a reducer and a transmission link connected to it. , The supporting steel ring 2 is connected with the transmission connecting rod in the rotating drive system 1, and the speed is continuously adjustable. The center line of the heating coil 10 is turned to a horizontal position, the heating coil 10 is fixed, ...

Embodiment 2

[0026] Others are the same as Embodiment 1, except that: the quartz ring zone melting boat 5 of the present invention is replaced with an upright melting crucible, and a corresponding mold can be set under the melting crucible according to the required shape and size; and the heating coil is installed On a bracket that can adjust the angle of 360°, the position of the heating coil can be rotated to heat the upright smelting crucible for smelting and casting operations. Since the heating coil is connected to the high-frequency power supply, the heating coil induction heating ensures the heat required for smelting the material, increases the heating speed, accelerates the melting speed, and effectively reduces the energy consumption. After the materials in the smelting crucible are melted by induction, pour the melt in the smelting crucible into the mold to cool, and the casting operation can be completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com