Electrostatic chuck and substrate temperature adjusting-fixing device

An electrostatic chuck and substrate technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of increased cost, disturbance of the temperature uniformity of the substrate 107, and complicated structure of the substrate 106, and achieves the realization of temperature uniformity, Achieving the effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

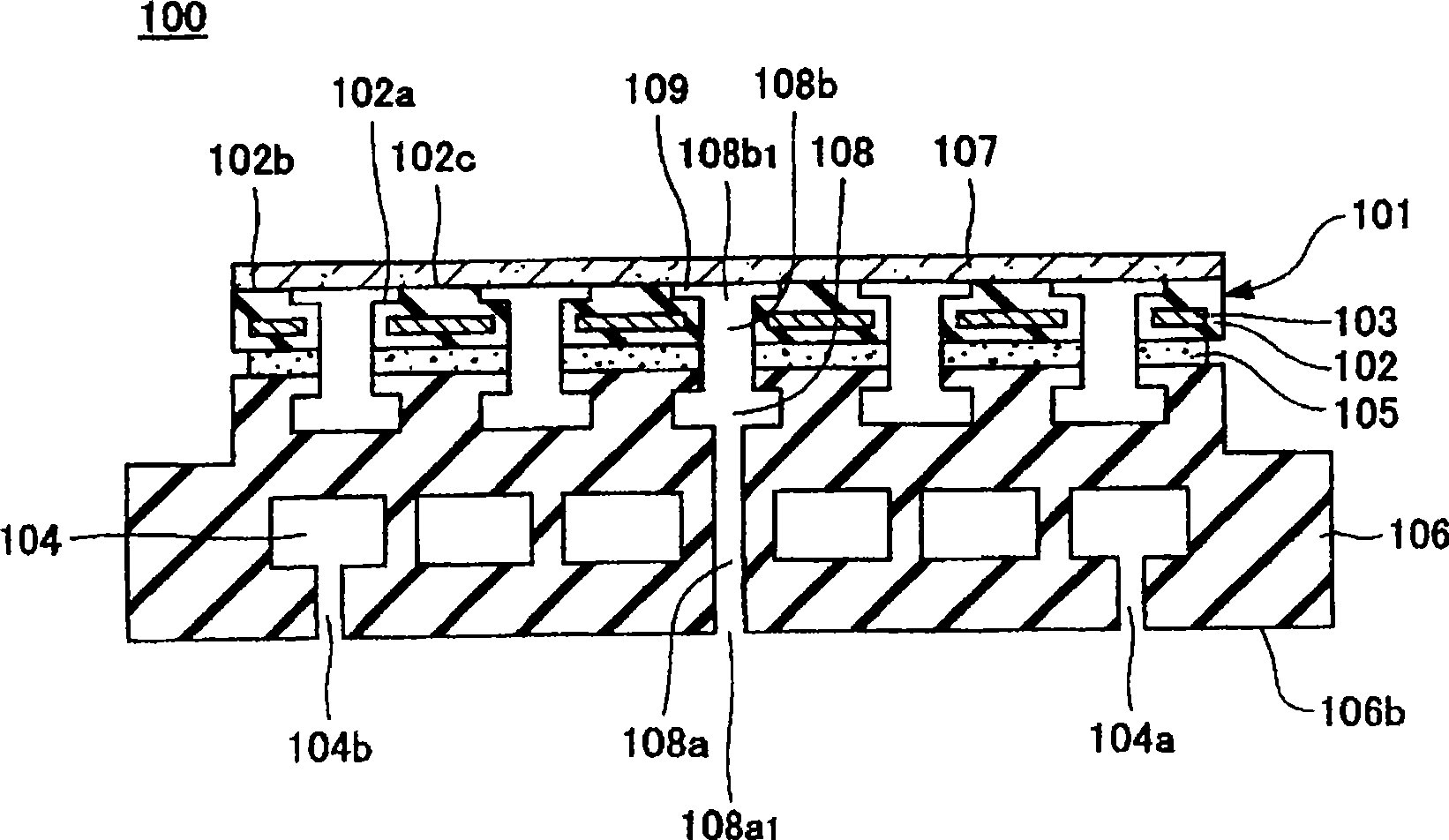

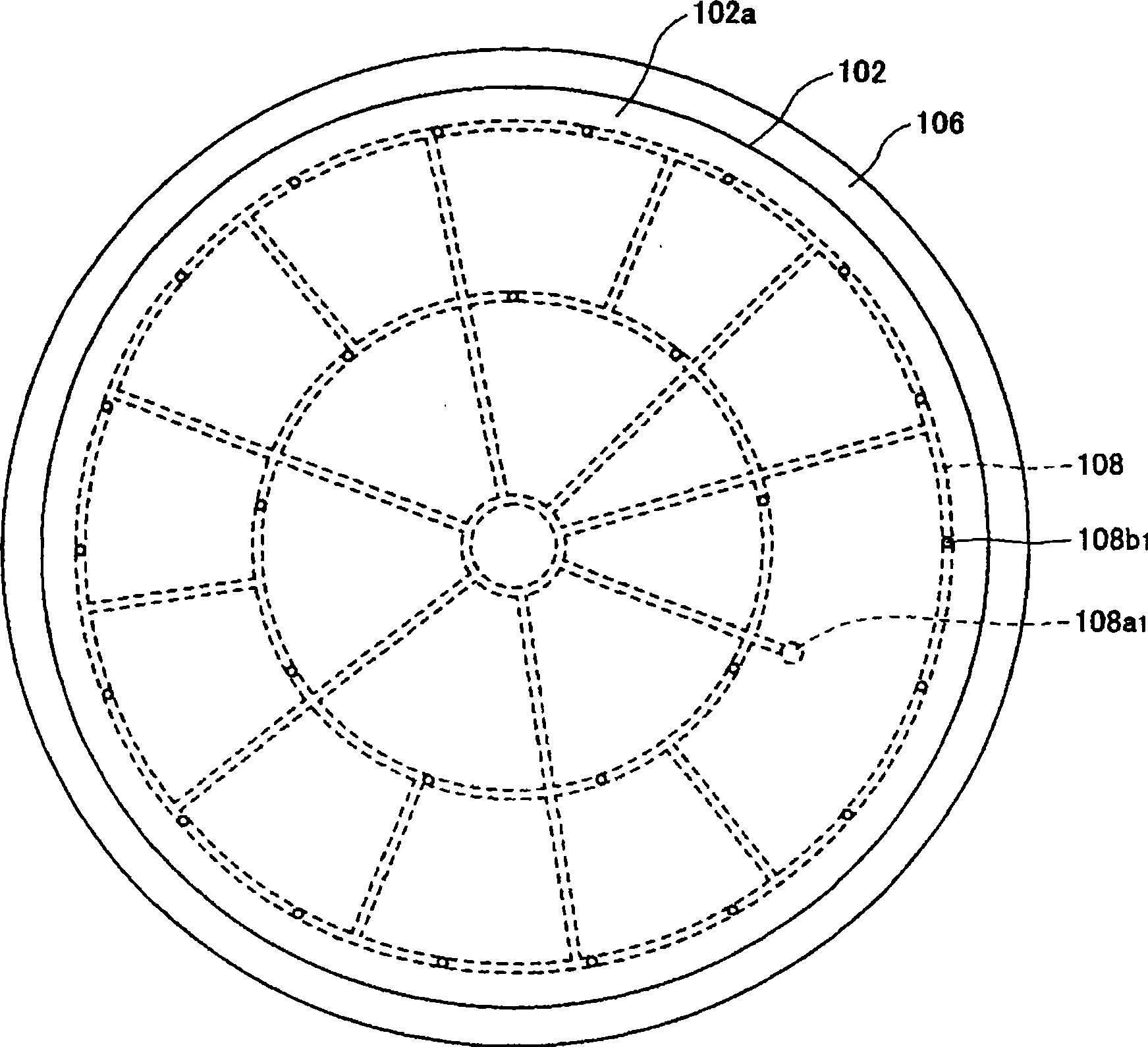

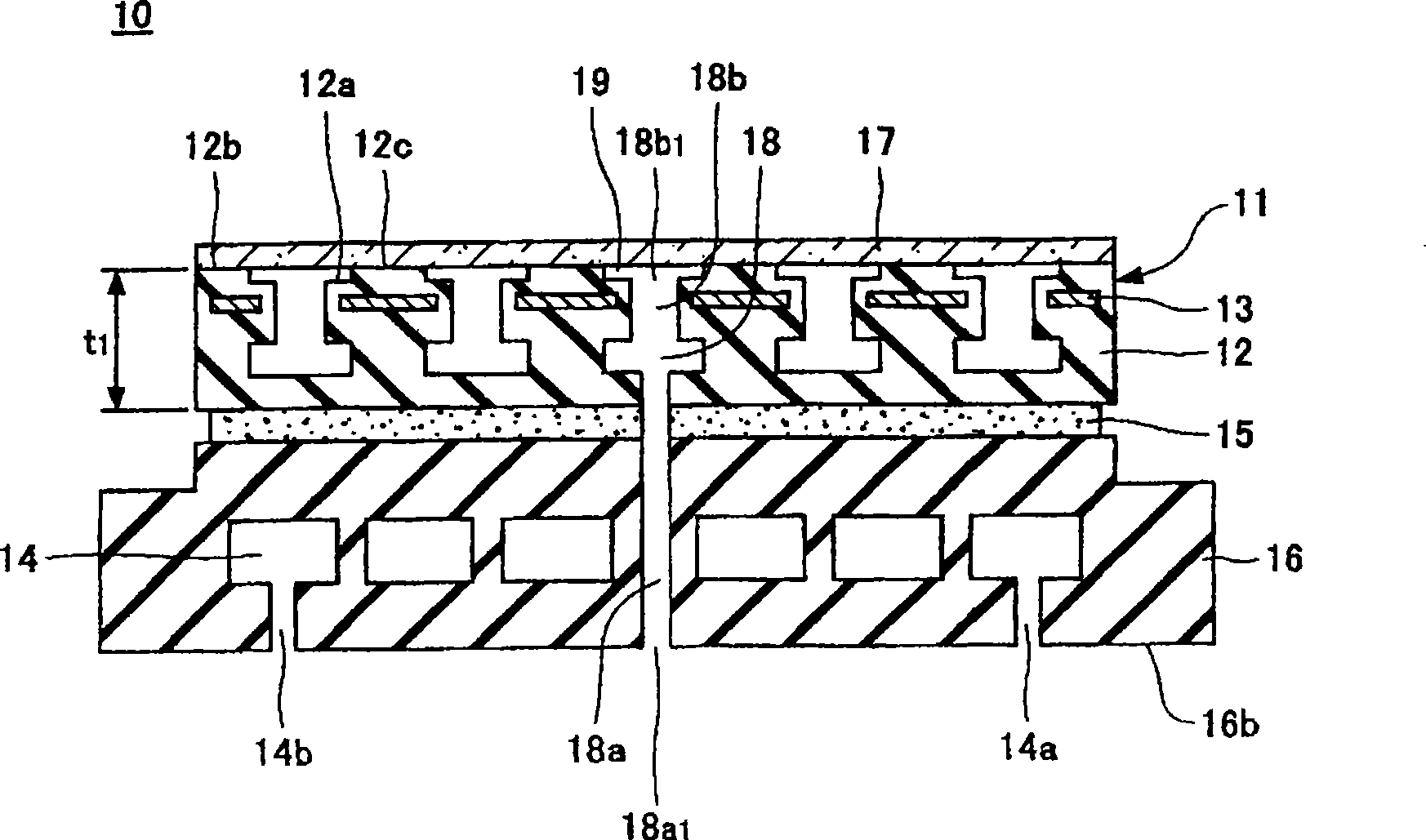

[0062] image 3 is a cross-sectional view showing a simplified example of the substrate temperature adjustment fixing device 10 according to the first embodiment of the present invention. like image 3 As shown, the substrate temperature regulation fixture 10 includes an electrostatic chuck 11 , an adhesive layer 15 , and a substrate 16 . Reference numeral 17 denotes a substrate held by the electrostatic chuck 11 in a suction state. For example, the substrate 17 is made of a silicon wafer or the like.

[0063] The electrostatic chuck 11 is a Coulomb force electrostatic chuck having a base 12 and an electrostatic electrode 13 . The base body 12 is a dielectric and is fixed on a substrate 16 by an adhesive layer 15 . For example, mainly by A1 2 o 3 Or ceramics composed of AlN can be used as the base body 12 .

[0064] For example, the thickness t of the substrate 12 1 is 2mm or more, for example, the specific permittivity (1KHz) of the substrate 12 is in the range of 9 t...

no. 2 example

[0090] In the substrate temperature adjustment fixing device 10 according to the first embodiment of the present invention, for example, in the case where the substrate 17 is made of a silicon wafer, when etching the substrate 17 which is a silicon wafer, RF (high frequency) can be applied to the substrate 16. When RF (high frequency) may be applied to the substrate 16 , a potential difference is generated in the gas path 18 , thereby generating an arc (abnormal discharge) in the gas path 18 in some cases.

[0091] In order to prevent an arc from being generated in the gas path 18, it is effective to perform a process that makes it difficult to generate a potential difference in the gas path 18. In the second embodiment, in order to prevent arcing in the gas path 18 , an example of a substrate temperature adjustment fixture having an electrostatic chuck subjected to a process that makes it difficult to generate a potential difference is shown here.

[0092] Also, in the subst...

no. 3 example

[0101] In the third embodiment of the present invention, in order to prevent arcing in the annular gas path 18, a substrate temperature adjustment fixture having an electrostatic chuck that has undergone a process that makes it difficult to generate a potential difference in the annular gas path 18 is shown here Another example of .

[0102] Figure 7is a cross-sectional view showing a simplified example of a substrate temperature adjustment fixing device 30 according to a third embodiment of the present invention. In the same drawings, the same reference numerals are given to the same components as in the substrate temperature adjustment fixing device 10 according to the first embodiment of the present invention, and descriptions thereof are omitted. like Figure 7 As shown, the substrate temperature adjustment fixture 30 includes an electrostatic chuck 31 , an adhesive layer 15 , and a substrate 16 .

[0103] The electrostatic chuck 31 is a Coulomb force electrostatic chu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com