Method for making battery positive plate and positive electrode slurry thereof

A technology of a battery positive electrode and a manufacturing method, which is applied to battery electrodes, alkaline battery electrodes, circuits, etc., can solve the problems of easy falling off, high internal resistance of batteries, falling off of pole piece powder, etc., so as to improve electrochemical performance and improve electrical conductivity. performance, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A method for making a nickel-hydrogen, nickel-cadmium battery positive plate, comprising the following steps:

[0036] 1) Making a cut-and-drawn steel mesh, processing the cold-rolled sheet into a cut-and-drawn steel mesh, and coating the outer surface of the cut-and-drawn steel mesh with a nickel layer.

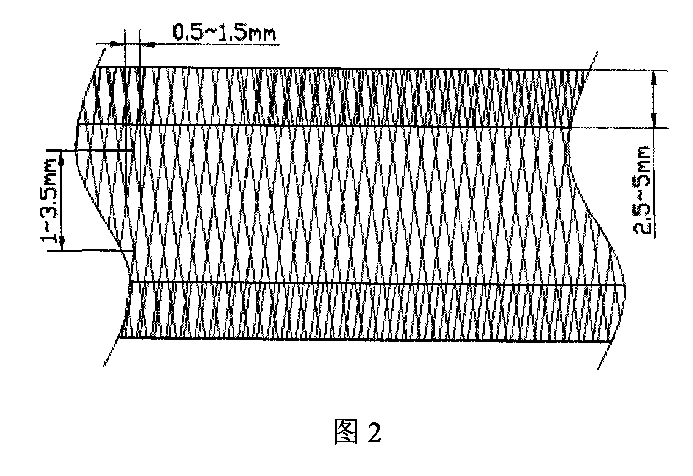

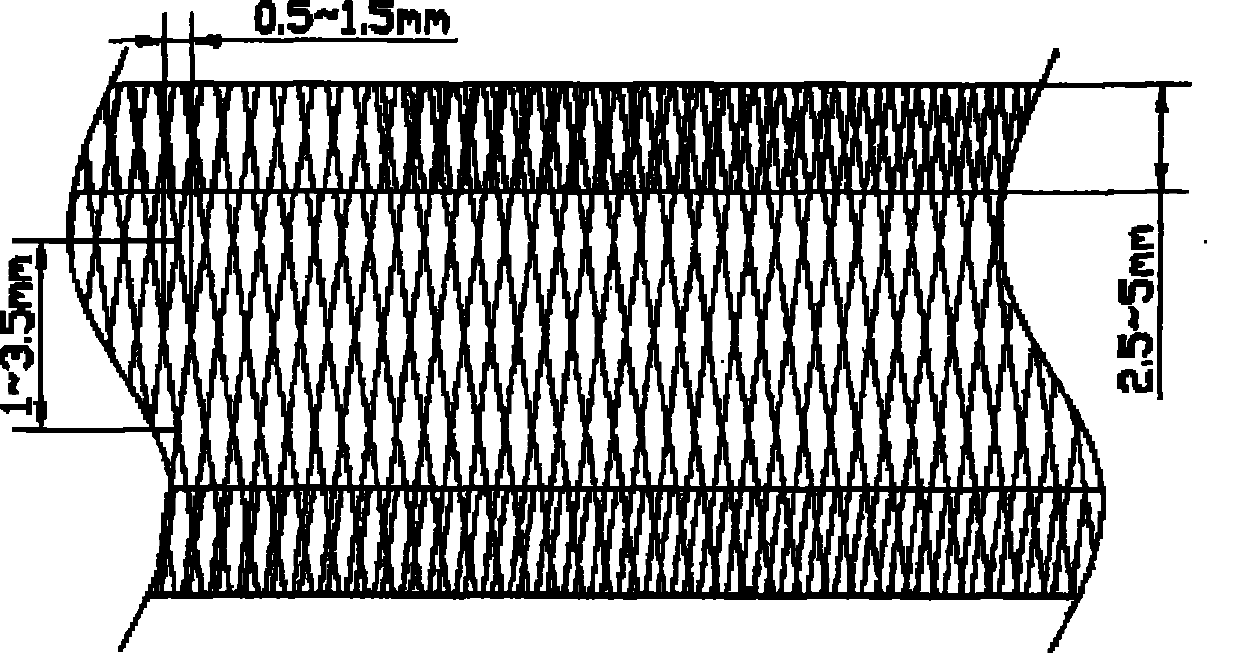

[0037] As shown in Figure 2, the cut-and-drawn steel mesh is used as the conductive framework of the positive electrode of the nickel-metal hydride and nickel-cadmium batteries. The maximum diagonal distance in the mesh is 1.0mm to 3.5mm, and the minimum diagonal distance is 0.5mm to 1.5mm. The thickness of the cut-and-drawn steel mesh is 0.15mm-0.40mm, and there are folded edges with a width of 2.5mm-5.0mm on both sides. The surface density of the cut-and-drawn steel mesh is 150g / m 2 ~240g / m 2 , and a nickel electroplating layer with a thickness of 0.001 mm to 0.005 mm is electroplated on its outer surface.

[0038]The special mesh structure of the stencil mesh h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com