Three-effect catalyst for purifying exhaust of lean-burn automotive and preparation method thereof

A lean-burn engine, three-way catalyst technology, applied in combustion engines, internal combustion piston engines, physical/chemical process catalysts, etc. Good thermal stability, improved catalytic performance, and high low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

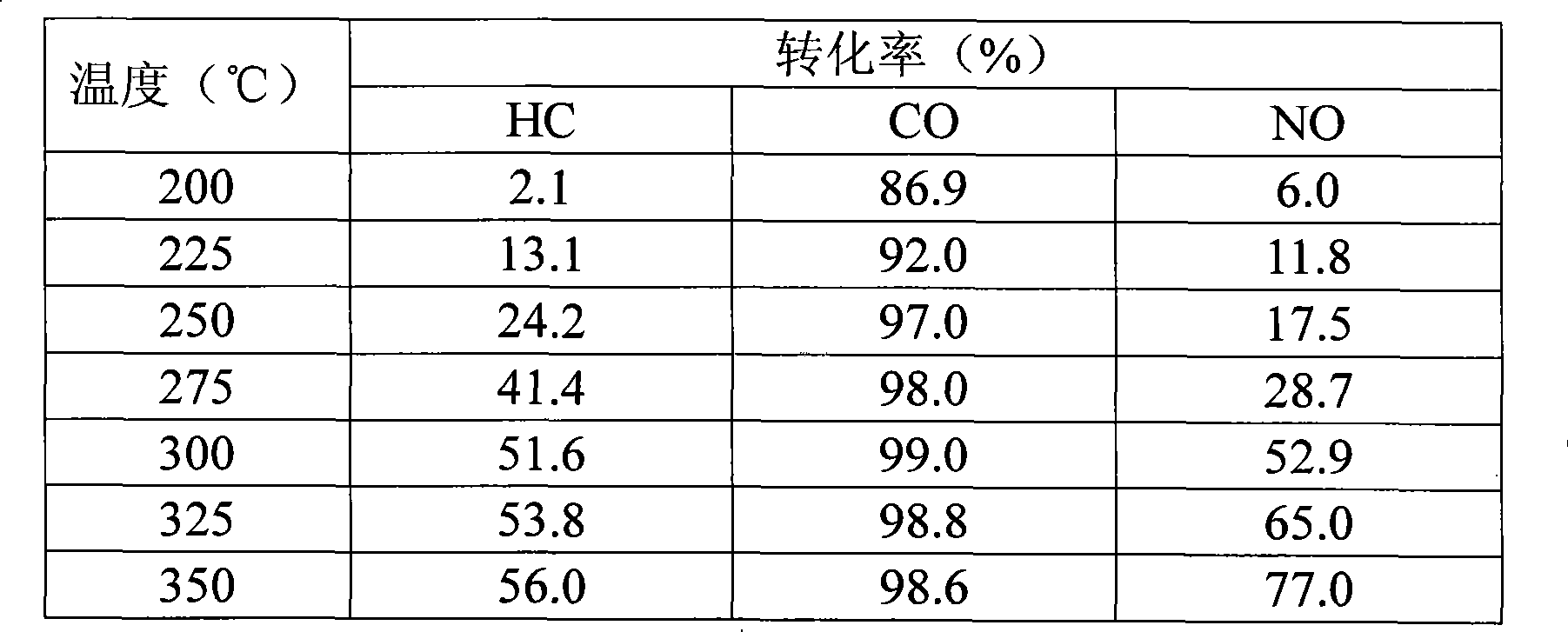

[0024] Embodiment 1: CeCuO 3-λ The catalytic effect of the catalyst

[0025] Ce(NO at a molar ratio of 1:1 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O is added to deionized water, under constant temperature conditions of 80°C, fully stirred, after completely dissolving, add citric acid to the solution, the molar ratio of citric acid to the sum of metal ions is 1.5: 1, and continue to stir at 80°C, After 30 minutes, 25 wt% ammonia water was added dropwise to the solution until the pH value was adjusted to 7. After the gel is formed, put the gel into an oven and dry it at 115°C for 48 hours. Then it is calcined at two stages of temperature: 500° C. for 4 hours, and 800° C. for 2.5 hours to prepare the oxide composition catalyst of cerium and copper.

[0026] Due to Ce 3+ The oxide is partially oxidized to Ce during the calcination process 4+ Oxide, Cu 2+ The oxide is partially reduced to Cu during the calcination process + Oxide, for the convenience of expression, the prep...

Embodiment 2

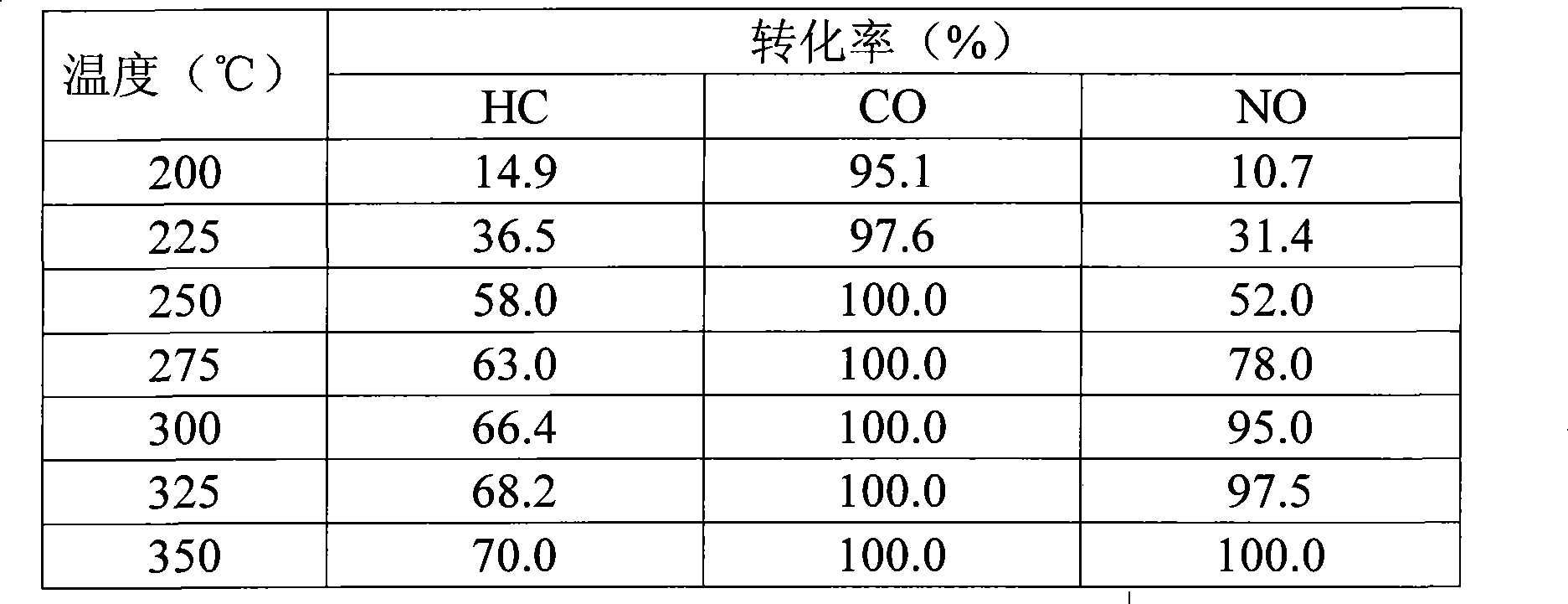

[0030] Embodiment two: Zr 0.6 Ce 0.4 CuO 3-λ The catalytic effect of the catalyst

[0031] Zr(NO 3 ) 4 ·5H 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O is added to deionized water, and Zr is obtained by the method of Example 1 0.6 Ce 0.4 CuO 3-λ Catalyst, and test activity under the activity evaluation condition of embodiment one. The conversion rates of HC, CO and NO on this catalyst are as follows:

[0032]

[0033] Visible, from the above Zr 0.6 Ce 0.4 CuO 3-λ Catalyst purification treatment simulates lean-burn motor vehicle exhaust. CO can be completely removed at 250-350°C, NO can be basically removed at 300-350°C, and HC removal effect exceeds 60%.

Embodiment 3

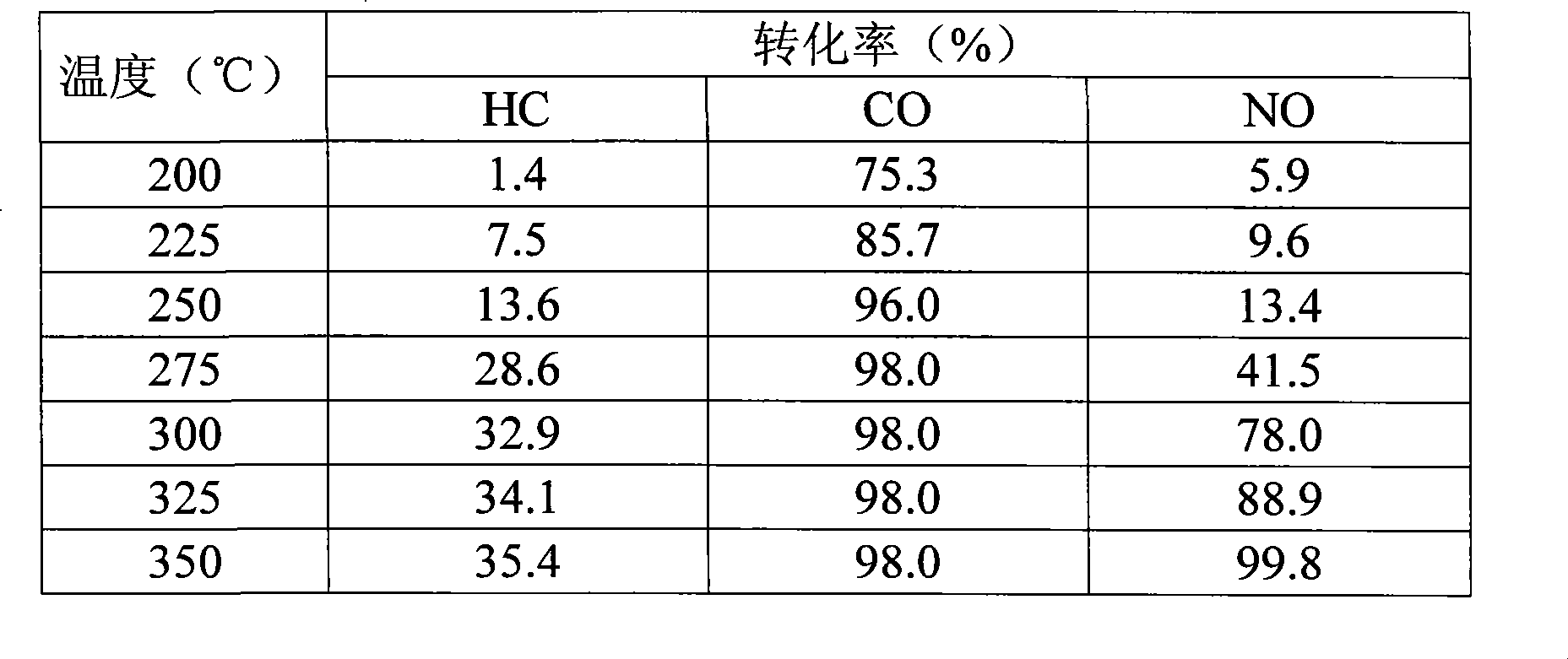

[0034] Embodiment three: Zr 0.8 Ce 0.2 CuO 3-λ The catalytic effect of the catalyst

[0035] Zr(NO 3 ) 4 ·5H 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O is added to deionized water, and Zr is obtained by the method of Example 1 0.8 Ce 0.2 CuO 3-λ Catalyst, and test activity under the activity evaluation condition of embodiment one. The conversion rates of HC, CO and NO on this catalyst are as follows:

[0036]

[0037] Visible, from the above Zr 0.8 Ce 0.2 CuO 3-λ Catalyst purification treatment simulates lean-burn motor vehicle exhaust, CO can be basically removed at 250-350°C, and NO can be removed by more than 78% at 300-350°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com