Production method of ultralong welding rail and production chain

A production method and technology of a production line, applied in the field of production methods and equipment for super-long welded rails, can solve the problems of increased time consumption and related costs, increased complexity of rails, and reduced fracture toughness of rails, so as to improve service life and modify parameters Convenience and the effect of reducing the number of track changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

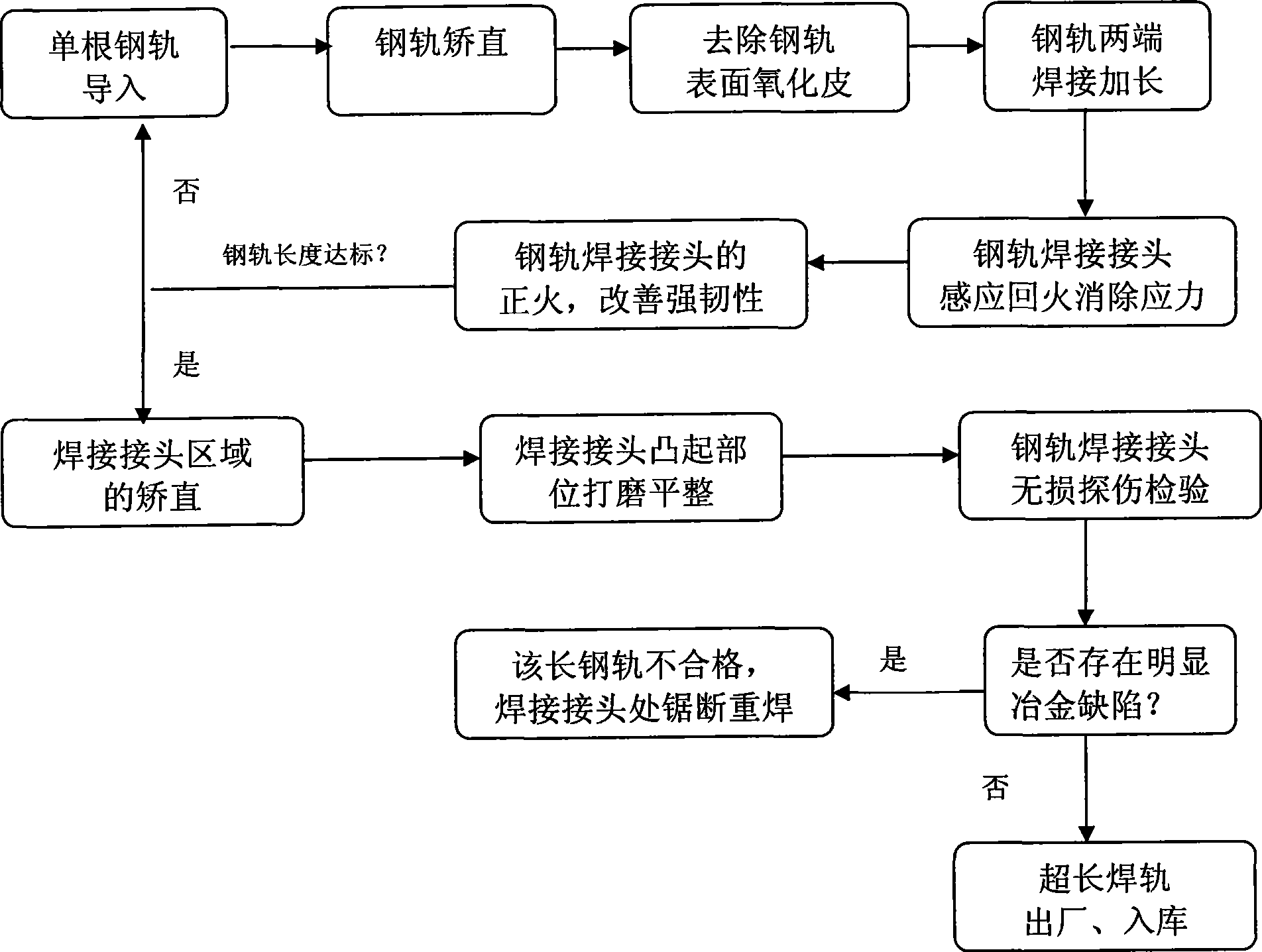

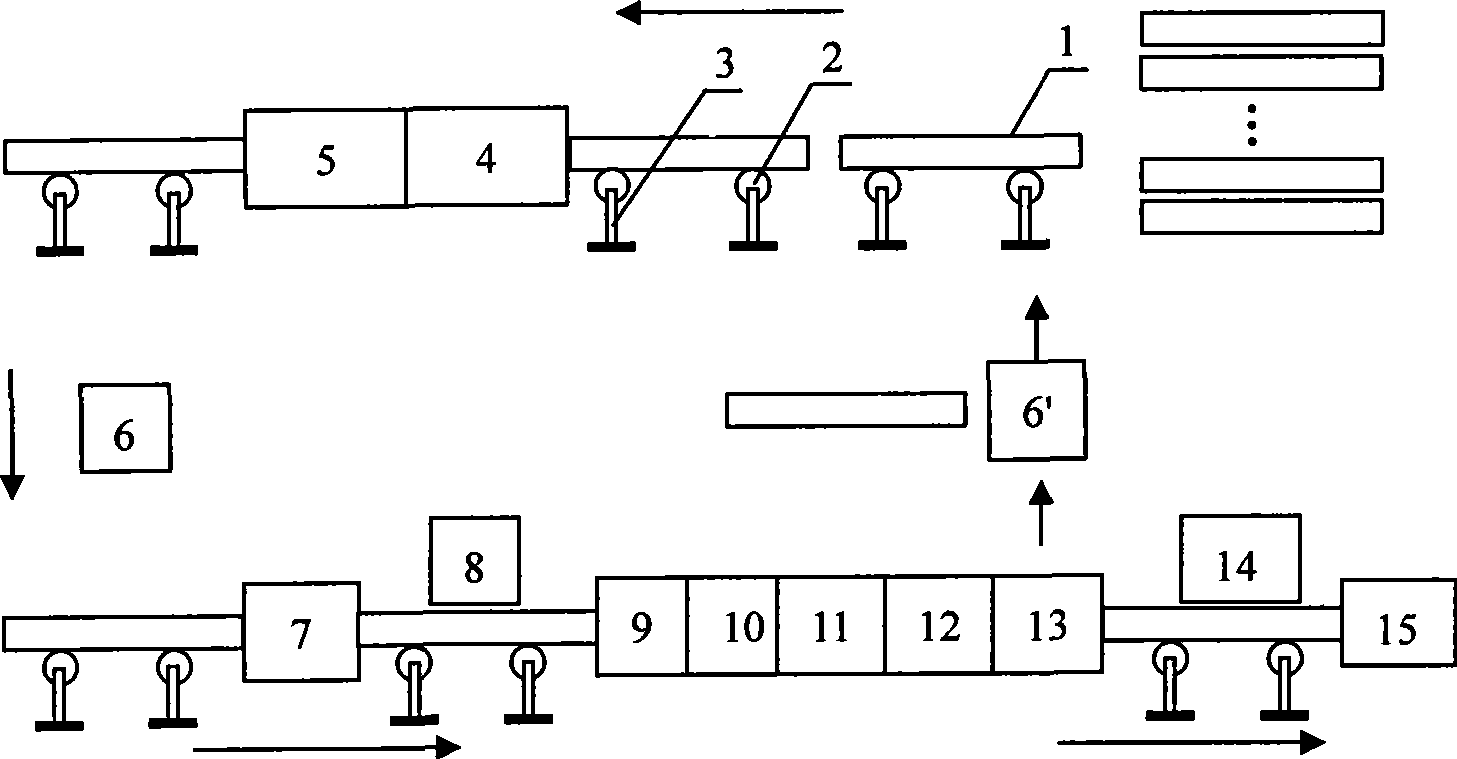

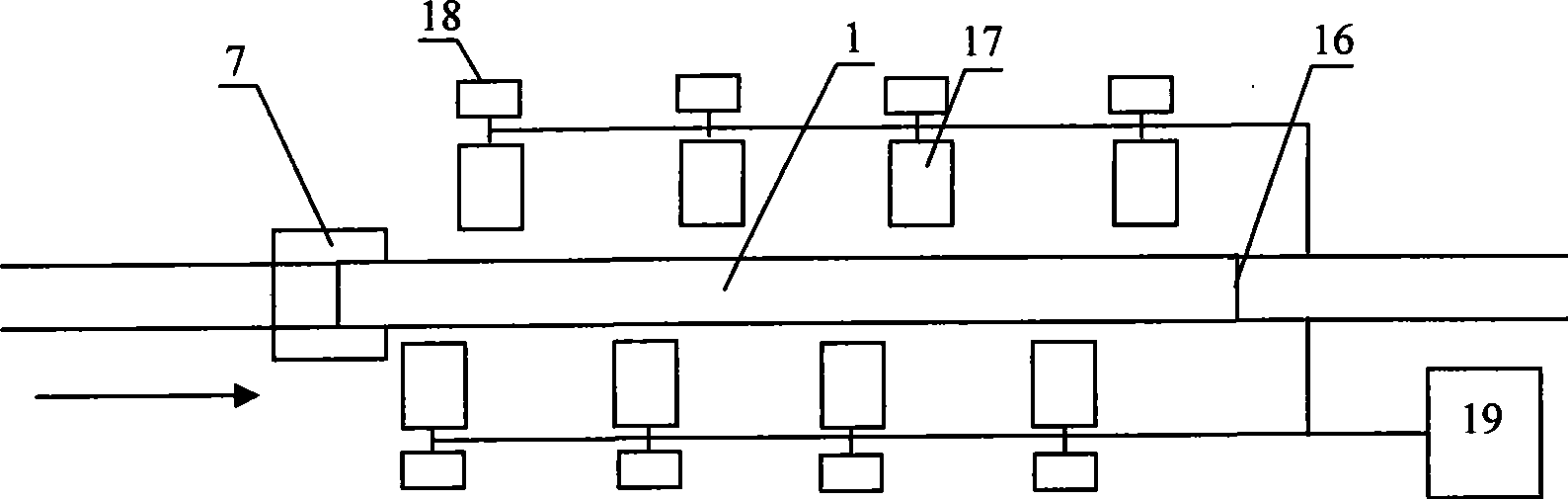

[0029] The production methods of the existing ultra-long welding rails at home and abroad usually include straightening, descaling, welding, tempering and normalizing, weld straightening, smoothing and non-destructive testing procedures. After the process, the steel rail is subjected to laser surface toughening treatment. In principle, the laser surface toughening treatment process is carried out after any process of the entire production process, but in order to make reasonable use of the workshop space of the existing ultra-long welded rail production line without reducing the production cycle and efficiency of the existing ultra-long welded rail production line , and finally proceed in the following two ways:

[0030] One is: the laser surface toughening treatment is carried out in two stages. The first stage is to perform laser surface toughening treatment on the part except the welded joint area at the same time as the rail is welded. Finally, the laser surface toughenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com