Preparation method of 1,1-cyclohexanediacetic acid

A kind of technology of cyclohexyl diacetic acid and cyclohexyl diacetic acid crude product, applied in 1 field, can solve the problems such as low product yield, environmental pollution, and three wastes are difficult to handle, and achieve high product yield, save equipment investment, and reduce production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

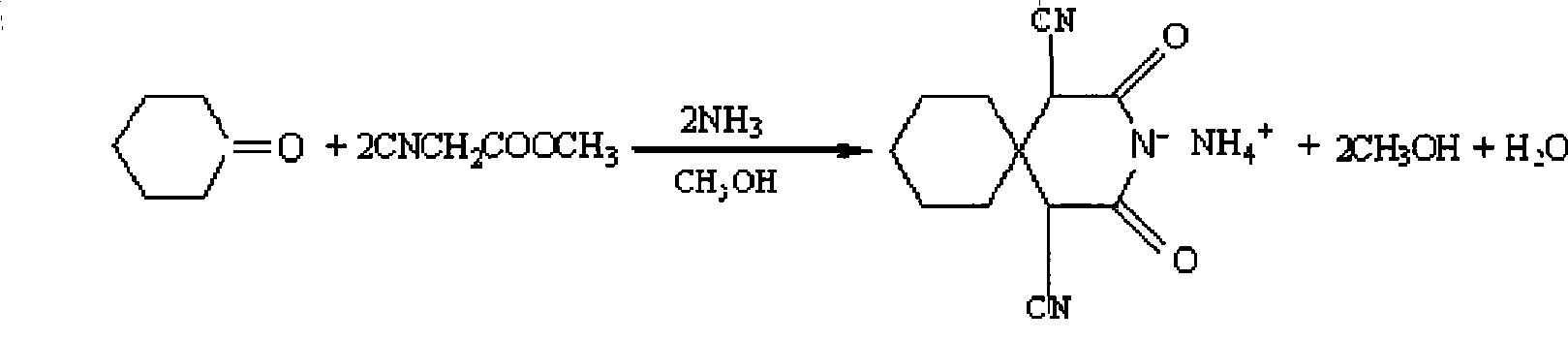

[0070] (1) Preparation of 1,1-cyclohexyl dicyanoamide

[0071] Add 135ml of methanol into the reaction vessel, pass 10.5g of ammonia gas under the condition of cooling and stirring, cool down to -10°C, then add 51.5g of methyl cyanoacetate, the reaction temperature rises to -7°C, then cools down to -10°C, Add 25g of cyclohexanone dropwise (the temperature does not exceed -6°C during the dropwise addition), and drop it in about 40 minutes, then stir for half an hour, cool down to -10°C, stop stirring, and keep warm at -10°C for 24 hours, 0± Incubate at 5°C for 12 hours, at room temperature at 25°C for 12 hours (48 hours in total), filter the methanol solution with suction to obtain 1,1-cyclohexyl dicyanoamide, dry to obtain 1,1-cyclohexyldicyanoamide powder The pure 59.5g, yield 94.15%, enter the next step.

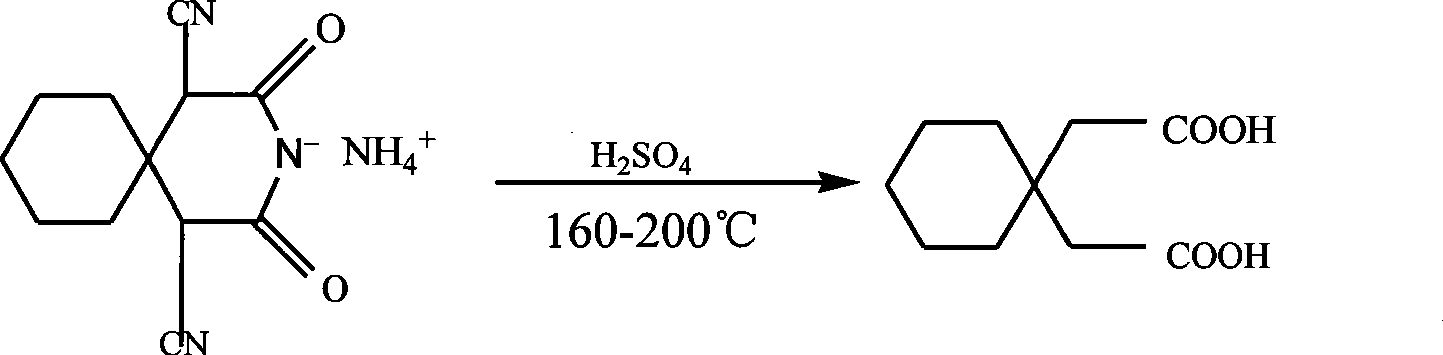

[0072] (2) Preparation of 1,1-cyclohexyl diacetic acid

[0073] (a) Add 70ml of water to the reaction vessel, slowly add 45ml of concentrated sulfuric acid, then add 59....

Embodiment 2

[0076] (1) Preparation of 1,1-cyclohexyl dicyanoamide

[0077] The mother liquor obtained by suction-filtering the methanol solution in step (1) of Implementation 1 is applied mechanically as follows: add 140ml of methanol mother liquor into the reaction vessel, feed 10g of ammonia gas under cooling and stirring conditions, cool down to -10°C, and then add cyanide Methyl acetate 51.5g, the temperature of the reaction was raised to -7°C, and then cooled to -10°C, 25g of cyclohexanone was added dropwise (the temperature did not exceed -6°C during the dropwise addition), and the drop was completed in about 40 minutes, stirred for half an hour, and cooled to -10°C, stop stirring, and then incubate at -10°C for 24 hours, at 0±5°C for 12 hours, and at room temperature 25°C for 12 hours (48 hours in total), and filter the methanol solution to obtain 1,1-cyclohexyldi Cyanamide was dried to obtain 60.6 g of pure 1,1-cyclohexyldicyanoamide powder, yield 95.88%, and proceeded to the next...

Embodiment 3

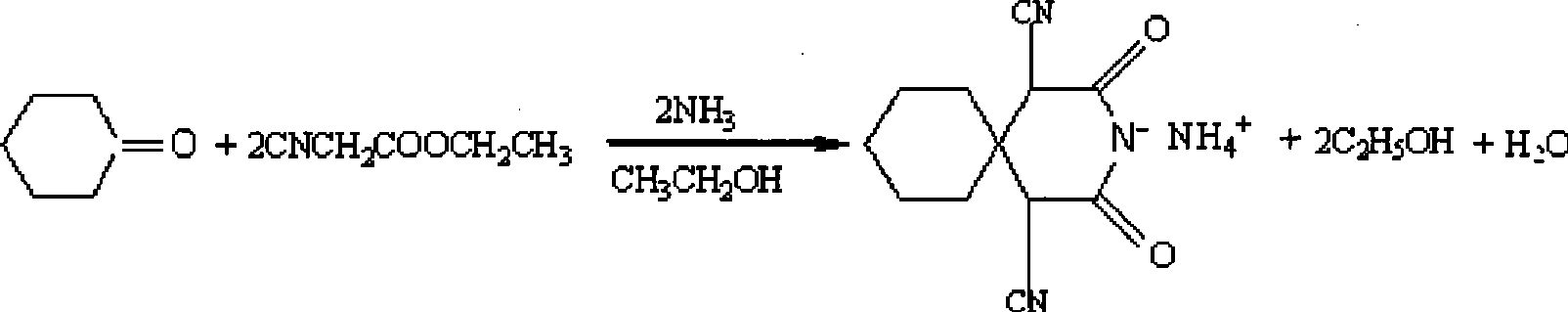

[0083] (1) Preparation of 1,1-cyclohexyl dicyanoamide

[0084] Add 140ml of absolute ethanol into the reaction vessel, pass 10.5g of ammonia gas under the condition of cooling and stirring, cool down to -10°C, then add 59.5g of ethyl cyanoacetate, the reaction temperature rises to -7°C, and then cools down to -10°C ℃, drop 25g of cyclohexanone (the temperature does not exceed -6 ℃ when dropping), drop it in about 40 minutes, then stir for half an hour, cool down to -10 ℃, stop stirring, and keep warm at -10 ℃ for 24 hours, Incubate at 0±5°C for 12 hours, at room temperature at 25°C for 12 hours (48 hours in total), filter the ethanol solution with suction to obtain 1,1-cyclohexyl dicyanoamide, and dry to obtain 1,1-cyclohexyl dicyanoamide The pure amide powder was 59.2 g, the yield was 93.67%, and the next step was carried out.

[0085] (2) Preparation of 1,1-cyclohexyl diacetic acid

[0086] (a) Add 70ml of water to the reaction vessel, slowly add 45ml of concentrated sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com