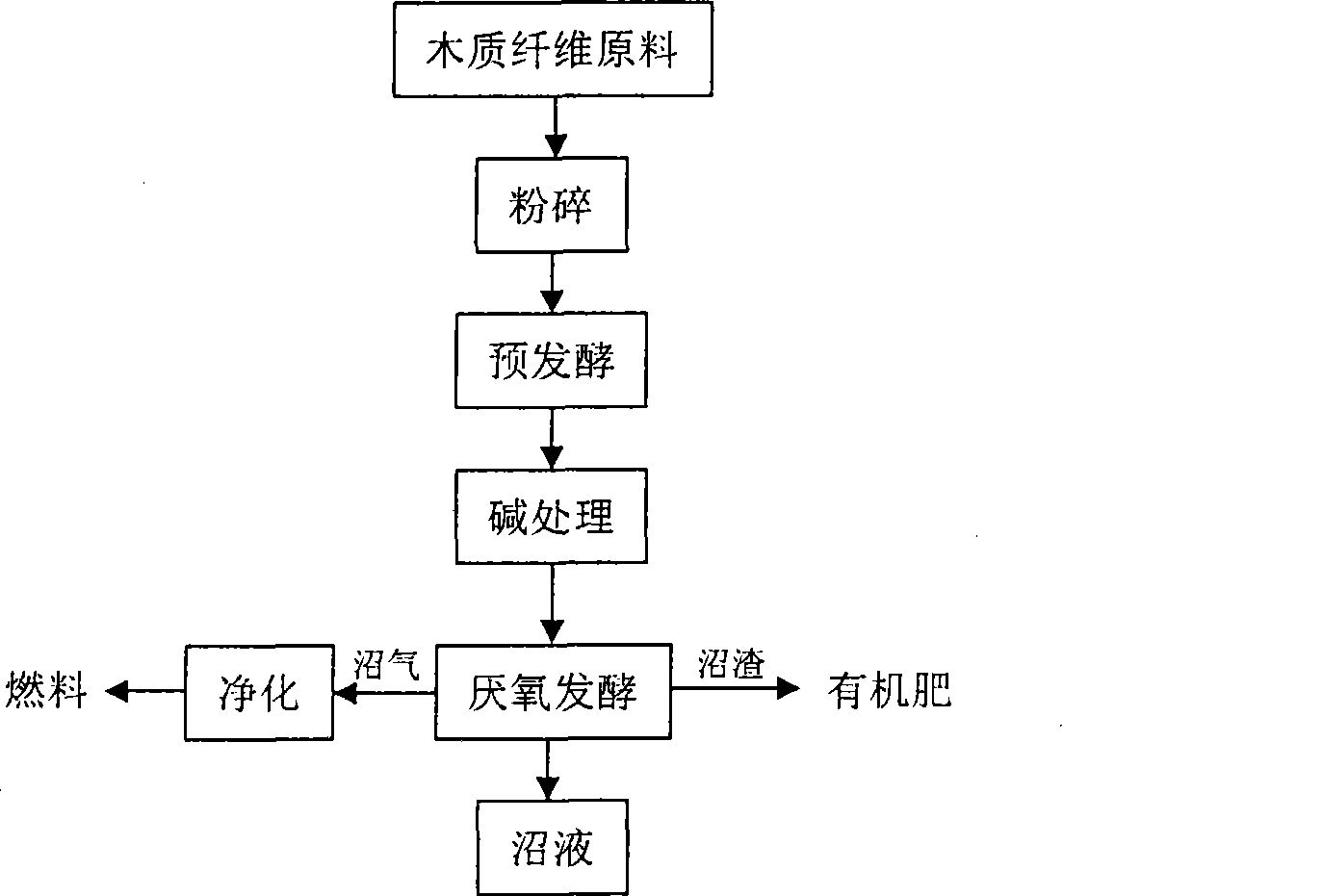

Novel wood fiber raw material anaerobic fermentation process

A lignocellulosic raw material, anaerobic fermentation technology, applied in the direction of fermentation, waste fuel, etc., can solve the problems of large amount of alkali, easy acidification, heavy pretreatment workload, etc., to reduce the amount of alkali, reduce the volume, and improve the processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cut the harvested lignocellulosic raw materials into small pieces of 1-2 cm by mechanical or manual methods, then put them into an anaerobic reactor, add inoculum for inoculation, mix, and the amount of inoculum added is 5% of the dry weight of the fermented product ~30%. Close the fermentation device, the gas outlet of the fermentation device is connected to the gas storage device through the gas transmission pipe, the reaction temperature is controlled at 35±1°C, the fermentation product is stirred by the stirring device during the fermentation process, and biogas can be generated within 24 hours. Afterwards, the gas production decreased significantly, and the reaction ended. The pre-fermented lignocellulosic raw material is taken out and dried, and the pre-fermented lignocellulosic raw material becomes loose and porous, with a volume reduction of more than 40% and a quality reduction of nearly 50%. Use 2% to 8% NaOH solution to soak the pre-fermented lignocellulosic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com