Temperature distortion resistant magnesium alloy containing Ca and Sr

A technology for heat-resistant deformation and magnesium alloys, applied in the field of heat-resistant deformation magnesium alloys and wrought magnesium alloys, to achieve the effects of good secondary deformation process performance, low cost, excellent elongation and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

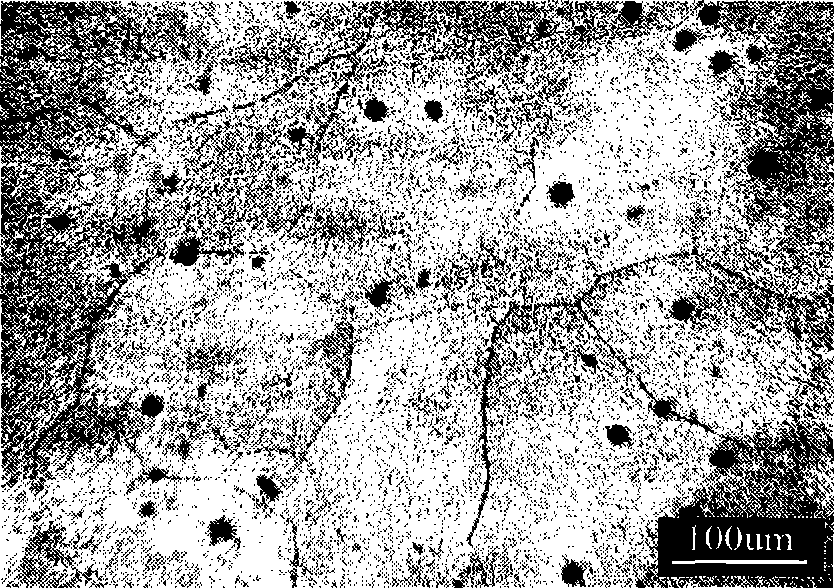

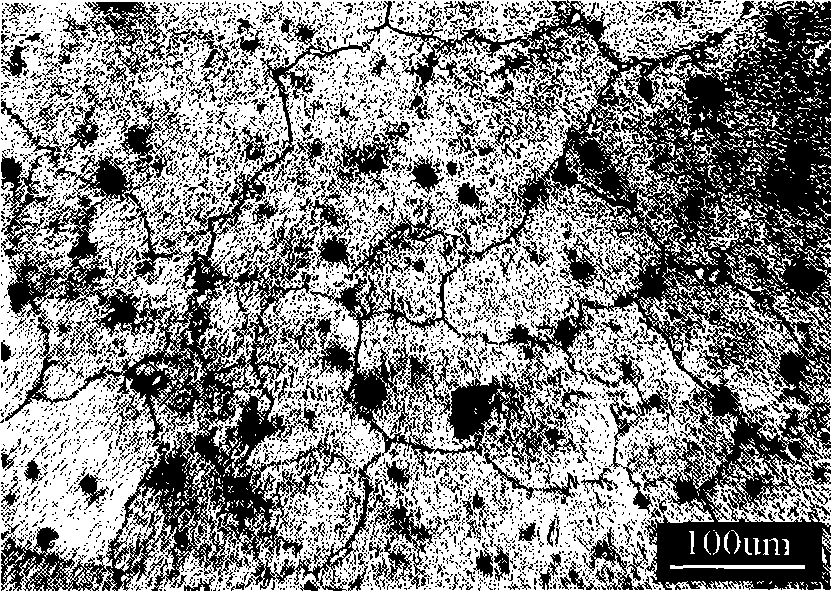

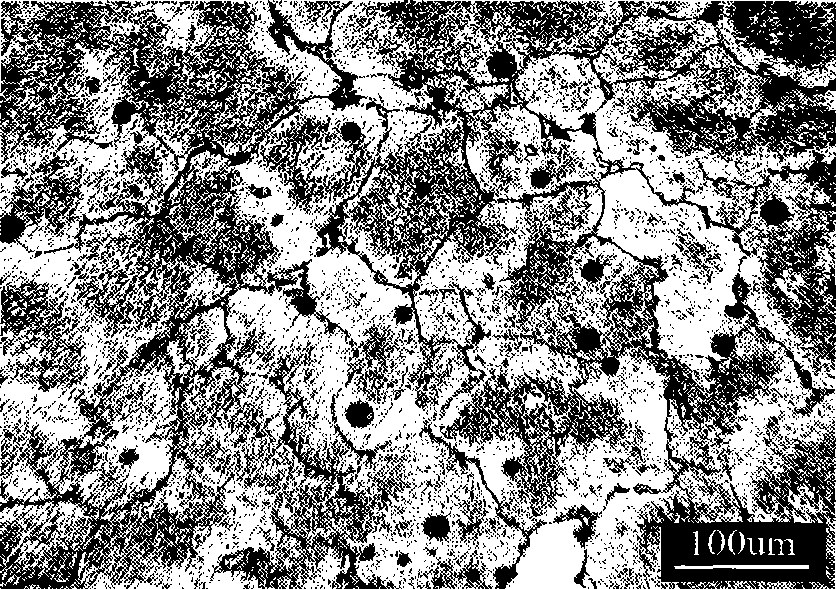

Image

Examples

Embodiment 1

[0028] Example 1: An advanced heat-resistant deformation magnesium alloy containing Ca and Sr, the weight percentage of each component in the magnesium alloy is 8% Al, 1.5% Ca, 0.2% Sr, 0.6% Mn, and the balance is Mg And trace inevitable impurities.

[0029] The alloys of Comparative Example 1, Comparative Example 2, and Example 1 can be prepared by the following preparation process steps:

[0030] (1) Under the protection of flux RJ-2, after the industrial pure magnesium is completely melted, industrial pure aluminum and industrial pure manganese are respectively added at 720°C, and the alloy of Comparative Example 2 is then added with an Al-Ca master alloy. Example 1 Add Al-Ca master alloy and Al-Sr master alloy to the alloy;

[0031] (2) After all the alloying elements are dissolved, stir the alloy with a stir bar at 740°C for about 10 minutes, and then stand at this temperature for 20 minutes;

[0032] (3) After the static is completed, in SO 2 Pour the alloy liquid steadily i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com