Water bath carbon dioxide vaporizer

A carbon dioxide and vaporizer technology, applied in the field of heat exchange, can solve the problems of cooling to about 30°C, energy consumption, energy consumption, etc., and achieve the effect of sufficient gas content, uniform temperature and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

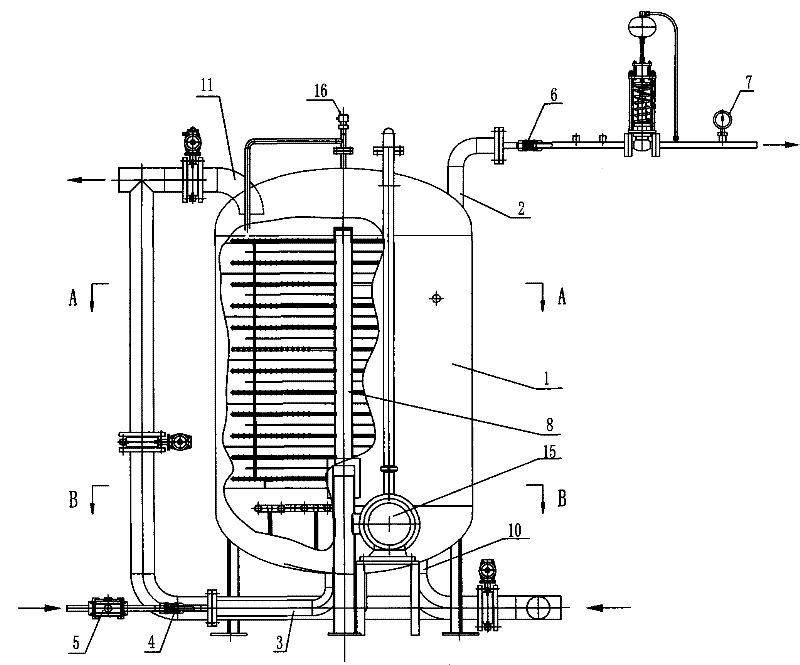

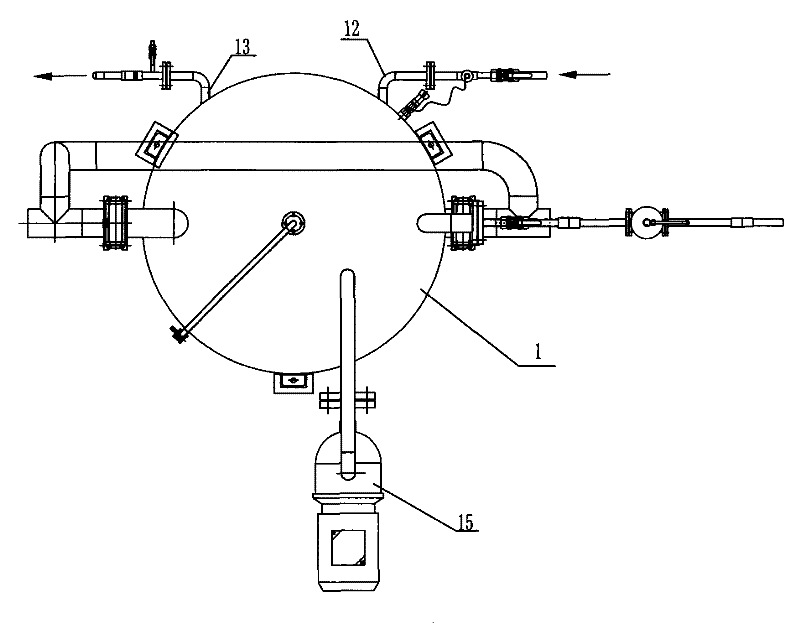

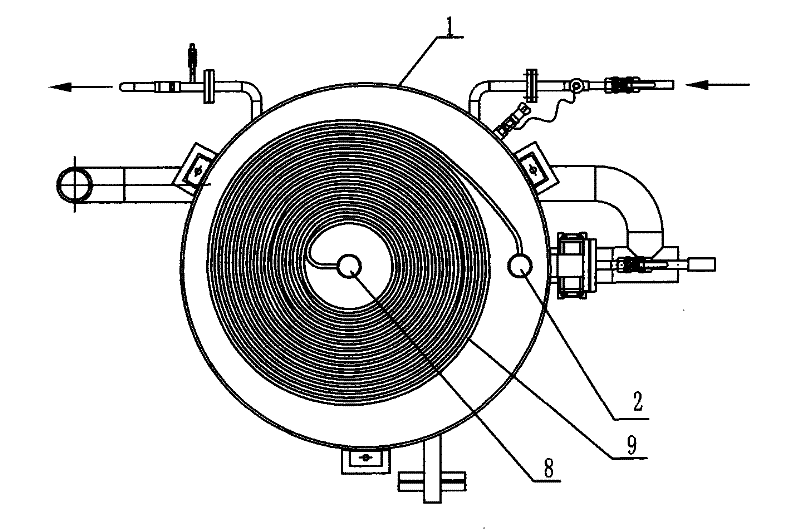

[0016] like figure 1 , 2 , 3, and 4, the upper and lower ends of the tank body 1 of the water-bath carbon dioxide vaporizer are respectively connected to the carbon dioxide outlet pipe 2 and the carbon dioxide liquid inlet pipe 3, and the outer end of the carbon dioxide liquid inlet pipe is connected to the pneumatic ball valve 5 through a three-piece welded ball valve 4 . The outer end of the carbon dioxide outlet pipe 2 is connected with an electric contact pressure gauge 7 through a three-piece welded ball valve 6 to achieve the purpose of automatically controlling the pneumatic ball valve.

[0017] The main pipeline 8 is vertically arranged in the tank body 1, the upper end of the main pipeline 8 is a closed end, the lower end is connected with the carbon dioxide liquid inlet pipe 3, and the coils 9 are evenly distributed along the length direction of the main pipeline 8, and one end of each coil 9 is connected to the main pipeline. The pipeline 8 communicates, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com