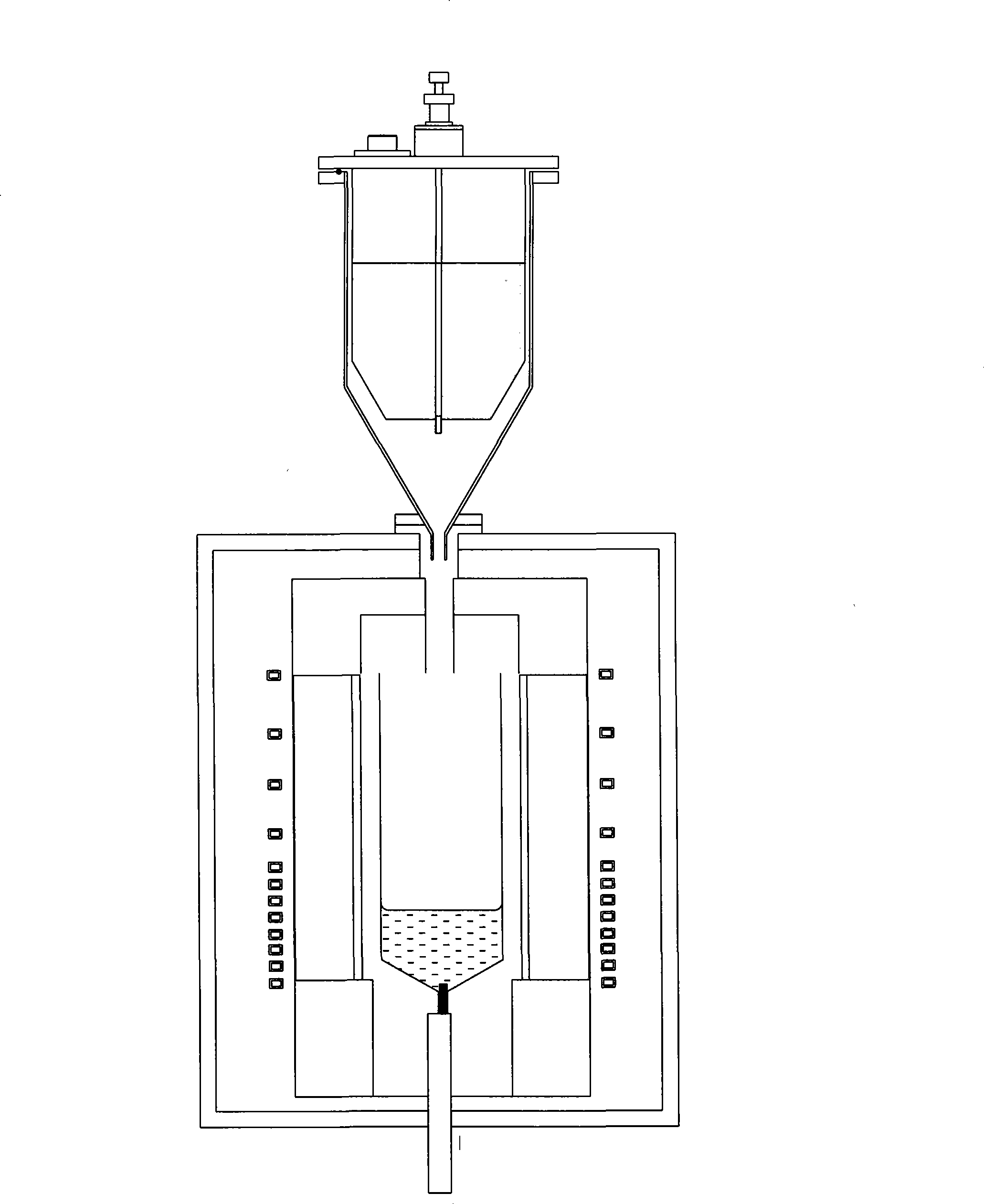

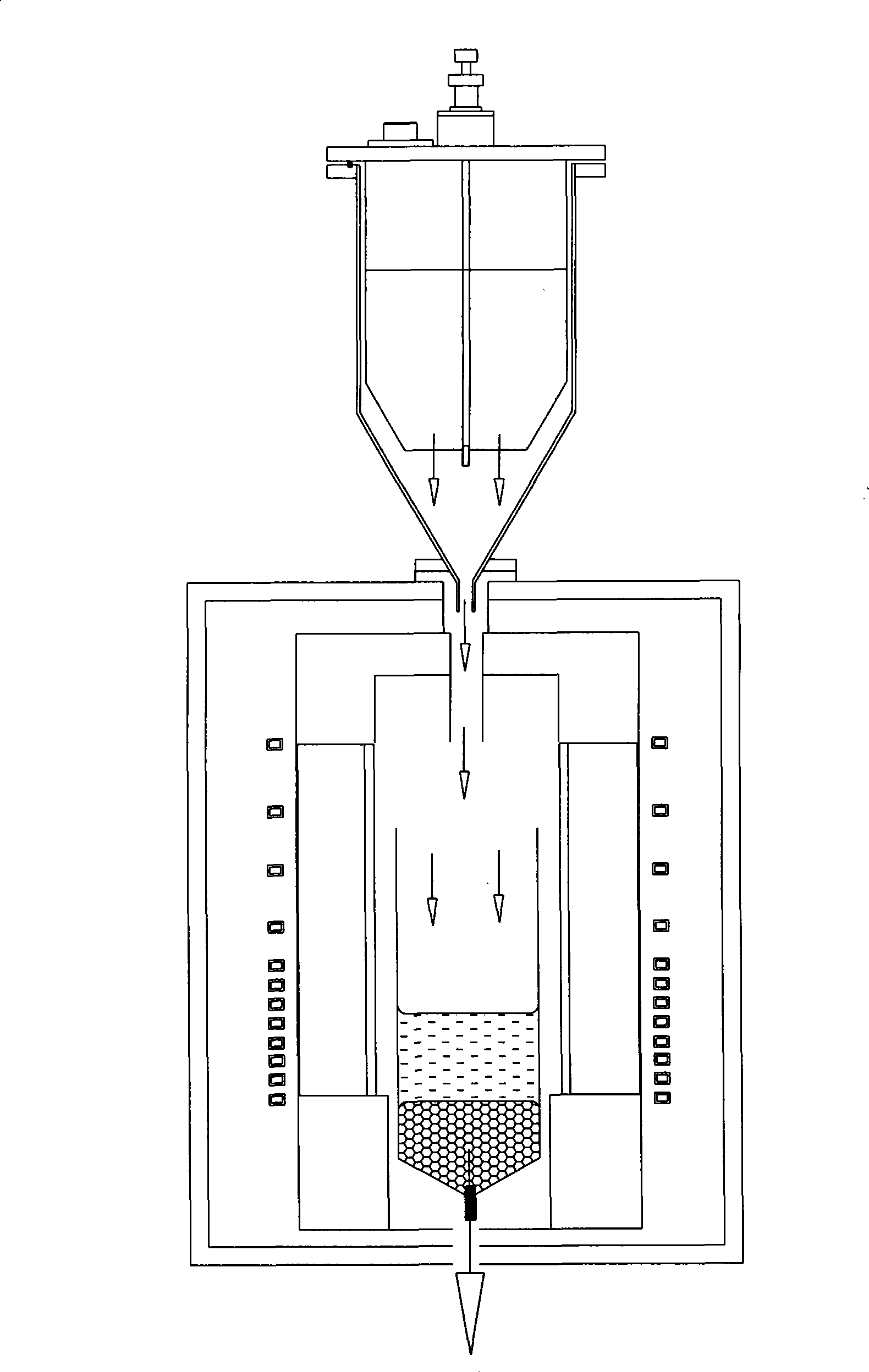

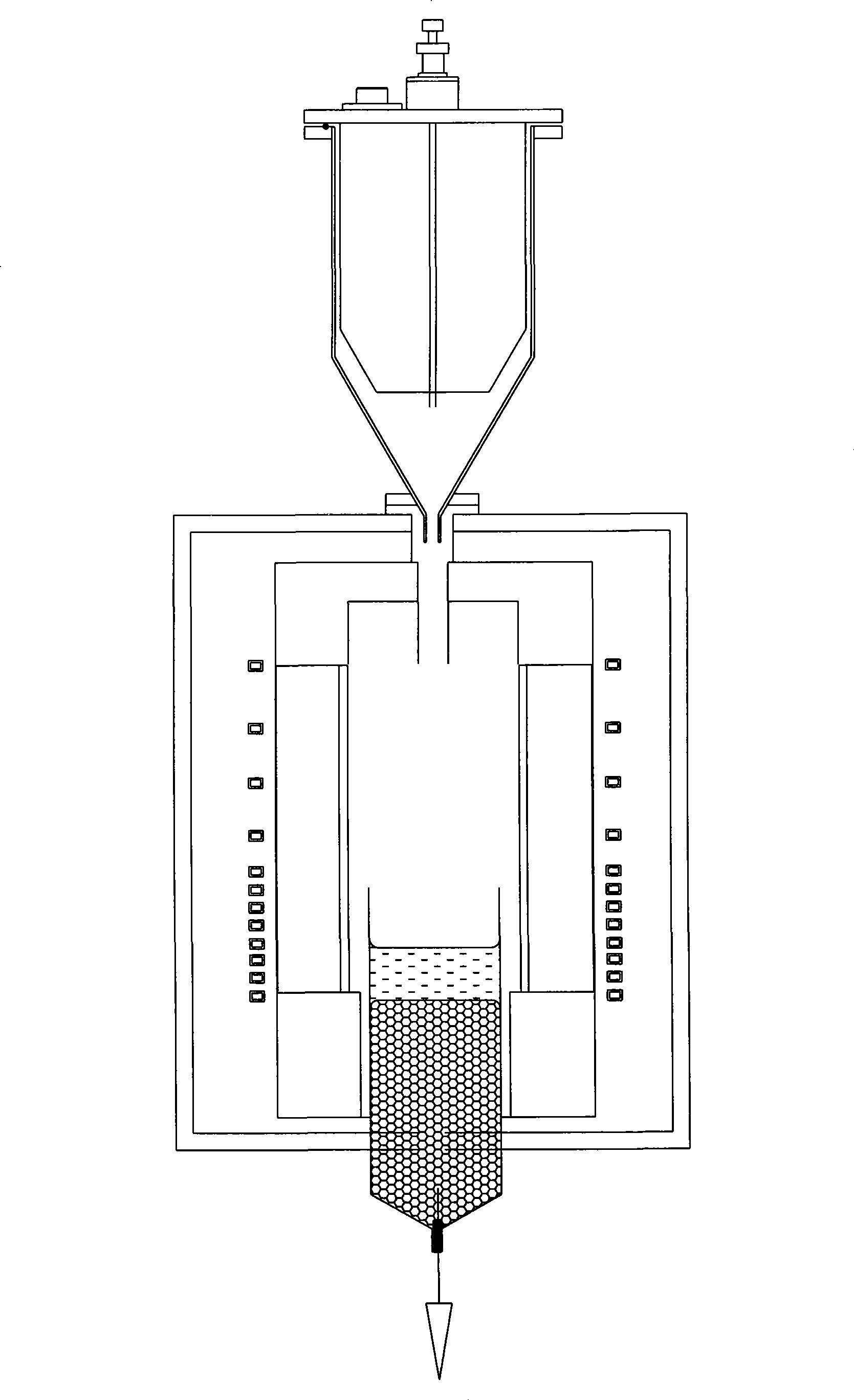

Novel technology for growth of yttrium-aluminum garnet crystal and equipment thereof

A new technology of yttrium aluminum garnet, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of large temperature gradient, limitation, and small crystal growth interface angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Growth neodymium ion concentration is 0.2% by weight of Nd 3+ :YAG crystal:

[0035] Will, 3Kg, the purity is 99.999% (5N level) doped neodymium (Nd 3+ ) The chemical reagent powder of yttrium aluminum garnet is packaged in a latex bag, which contains neodymium (Nd 3+ ) is 1% by weight; after packaging, it is compacted in a hydrostatic press with a pressure of 300MPa; after taking out the compacted neodymium (Nd 3+ ) yttrium aluminum garnet was sintered in the air at 1300° C. for 8 hours, and put it into the required crucible as a prefabricated raw material.

[0036] 12Kg of neodymium (Nd) doped with a purity of 99.999% (5N grade) 3+ ) The chemical reagent powder of yttrium aluminum garnet is packaged in a latex bag, which contains neodymium (Nd 3+ ) with a weight ratio concentration of 0.2%; after packaging, it is compacted in a hydrostatic press with a pressure of 300MPa; after taking out the compacted neodymium (Nd 3+ ) yttrium aluminum garnet raw material was s...

Embodiment 2

[0039] Growth neodymium ion concentration is 1% by weight of Nd 3+ :YAG crystal:

[0040] 3Kg of neodymium (Nd) doped with a purity of 99.999% (5N grade) 3+ ) The chemical reagent powder of yttrium aluminum garnet is packaged in a latex bag, which contains neodymium (Nd 3+ ) is 5% by weight; after packaging, it is compacted in a hydrostatic press with a pressure of 200MPa; after taking out the compacted neodymium (Nd 3+ ) yttrium aluminum garnet raw material was sintered in the air at 1300° C. for 8 hours, and put it into the required crucible as prefabricated raw material.

[0041] 12Kg of neodymium (Nd) doped with a purity of 99.999% (5N grade) 3+ ) The chemical reagent powder of yttrium aluminum garnet is packaged in a latex bag, which contains neodymium (Nd 3+ ) concentration by weight is 1%; after encapsulation, it is compacted under a pressure of 300MPa in a hydrostatic press; the neodymium-doped (Nd 3+ ) yttrium aluminum garnet was sintered in air at 1300° C. for 8...

Embodiment 3

[0044] Growth neodymium ion concentration is 1.5% by weight of Nd 3+ :YAG crystal:

[0045] 3Kg of neodymium (Nd) doped with a purity of 99.999% (5N grade) 3+ ) The chemical reagent powder of yttrium aluminum garnet is packaged in a latex bag, which contains neodymium (Nd 3+ ) is 7.5% by weight; after packaging, it is compacted in a hydrostatic press with a pressure of 200MPa; after taking out the compacted neodymium (Nd 3+ ) yttrium aluminum garnet raw material was sintered in the air at 1300° C. for 8 hours, and put it into the required crucible as prefabricated raw material. Accurately weigh 12Kg of neodymium (Nd) with a purity of 99.999% (5N grade) 3+ ) chemical reagent powder of yttrium aluminum garnet, which contains neodymium (Nd 3+ ) is 1.5% by weight. Sinter at 1300°C for 8 hours, and put it into the hopper of the feeding system as a supplementary material. Use a YAG crystal rod with a crystal orientation of (111), a diameter of 5mm, and a length of 50mm as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com