Cocoon shell recombinant nonwoven fabrics and manufacturing. method thereof

A manufacturing method and non-woven technology, applied in textiles and papermaking, non-woven fabrics, silk fiber production, etc., can solve problems such as failure to meet environmental protection requirements for daily necessities, great influence on silk quality, reduction of sericin, etc. The effect of non-repetition, expansion of use, and environmental protection of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. Natural colored cocoon shell cloth lampshade

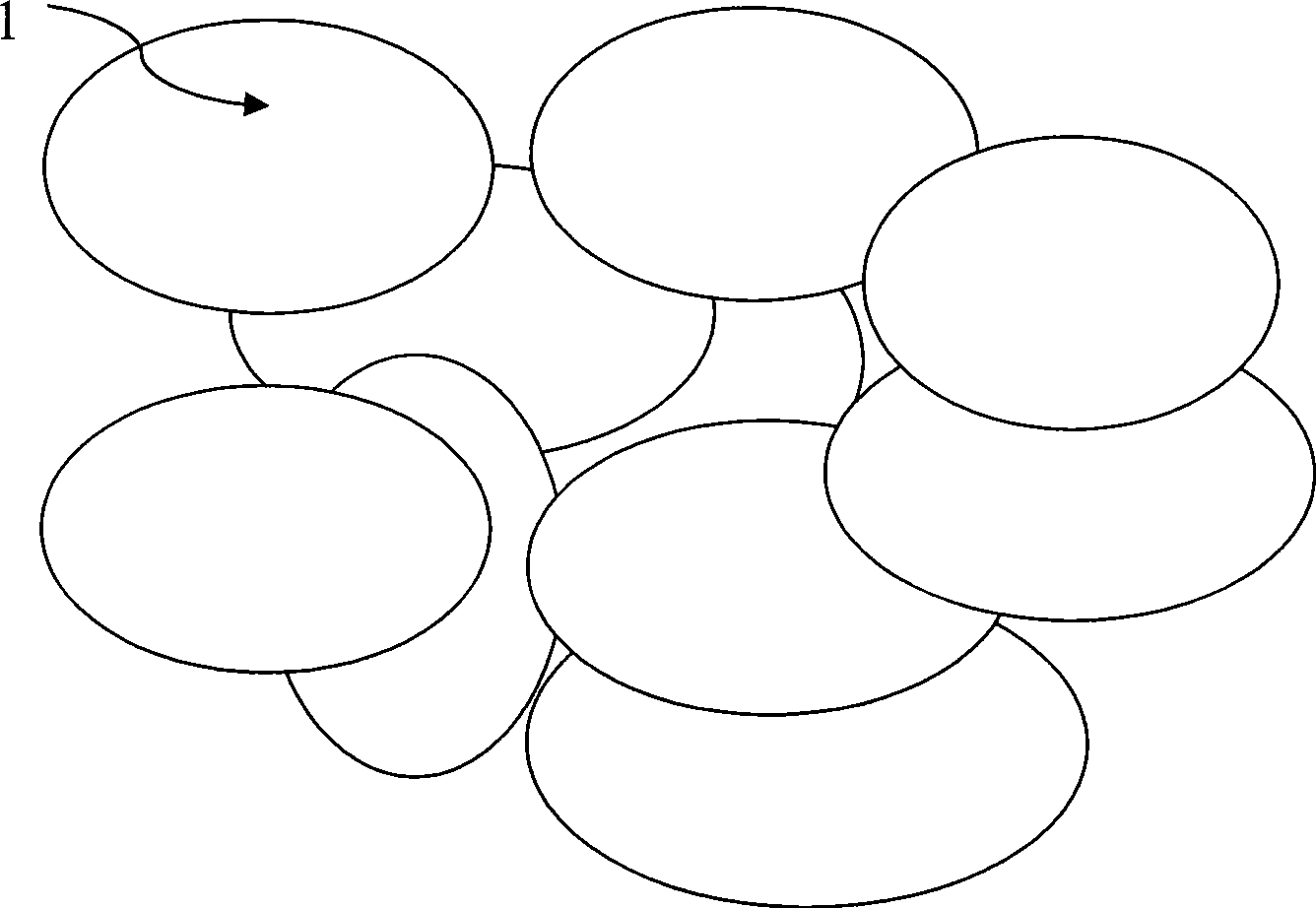

[0026] 1) Splitting the cocoon: For the elliptical cocoon, cut it in the direction of the long axis, and peel off the silkworm chrysalis;

[0027] 2) Cocoon peeling: the cocoon shell after cutting the cocoon is peeled off to 3-10 layers to form cocoon shell flakes;

[0028] 3) Laying: the lampshade is fixed, and the cocoon shell sheets are superimposed and laid according to the lampshade;

[0029] 4) Humidification: evenly spray water mist on the superimposed cocoon shell sheets, so that the cocoon shell sheets contain 5-50% moisture;

[0030] 5) Hot pressing: Use a hot pressing plate to carry out vertical hot pressing on the cocoon shell sheet at 70-100°C, and the hot pressing time is until the cocoon shell sheet is dry;

[0031] 6) Repair: Repair the insufficient part of the formed cocoon shell restructured non-woven fabric, humidify, heat, and pressurize again, and finally form the style of the lampshade....

Embodiment 2

[0032] Embodiment two, food packaging

[0033] 1) Splitting the cocoon: For the elliptical cocoon, cut it in the direction of the long axis, and peel off the silkworm chrysalis;

[0034] 2) Cocoon peeling: the cocoon shell after cutting the cocoon is peeled off to 3-10 layers to form cocoon shell flakes;

[0035] 3) Laying: superimposing and laying the cocoon shell sheets;

[0036] 4) Humidification: evenly spray water mist on the superimposed cocoon shell sheets, so that the cocoon shell sheets contain 5-50% moisture;

[0037] 5) Hot pressing: Use a hot pressing plate to carry out vertical hot pressing on the cocoon shell sheet at 70-100°C, and the hot pressing time is until the cocoon shell sheet is dry;

[0038] 6) Repair: Repair the insufficient part of the formed cocoon shell non-woven fabric, humidify, heat, heat press again, and finally form;

[0039] 7) Sterilize the formed cocoon shell restructured non-woven fabric with ultraviolet light or the like.

Embodiment 3

[0040] Embodiment three, cosmetic dressing

[0041] 1) Splitting the cocoon: For the elliptical cocoon, cut it in the direction of the long axis, and peel off the silkworm chrysalis;

[0042] 2) Cocoon peeling: the cocoon shell after cutting the cocoon is peeled off to 3-10 layers to form cocoon shell flakes;

[0043] 3) Laying: Make a fixed sample of the cosmetic surface, and lay the cocoon shell sheets according to the fixed sample;

[0044] 4) Humidification: evenly spray water mist on the superimposed cocoon shell sheets, so that the cocoon shell sheets contain 5-60% moisture;

[0045] 5) Hot pressing: Use a hot pressing plate to carry out vertical hot pressing on the cocoon shell sheet at 70-100°C, and the hot pressing time is until the cocoon shell sheet is dry;

[0046] 6) Repair: Repair the insufficient part of the formed cocoon shell non-woven fabric, humidify, heat and pressurize again, and finally form a cocoon shell non-woven fabric;

[0047] 7) Sterilize the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com