High-pressure cultivation system

A high-pressure, cultivation room technology, applied in the field of greenhouse cultivation systems, can solve the problems of difficult to adjust the air pressure value, the gas does not form a circulating flow, and is difficult to achieve, so as to improve the yield and quality of crops, reduce the occurrence of germs and pests, and improve the structure of the plant. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

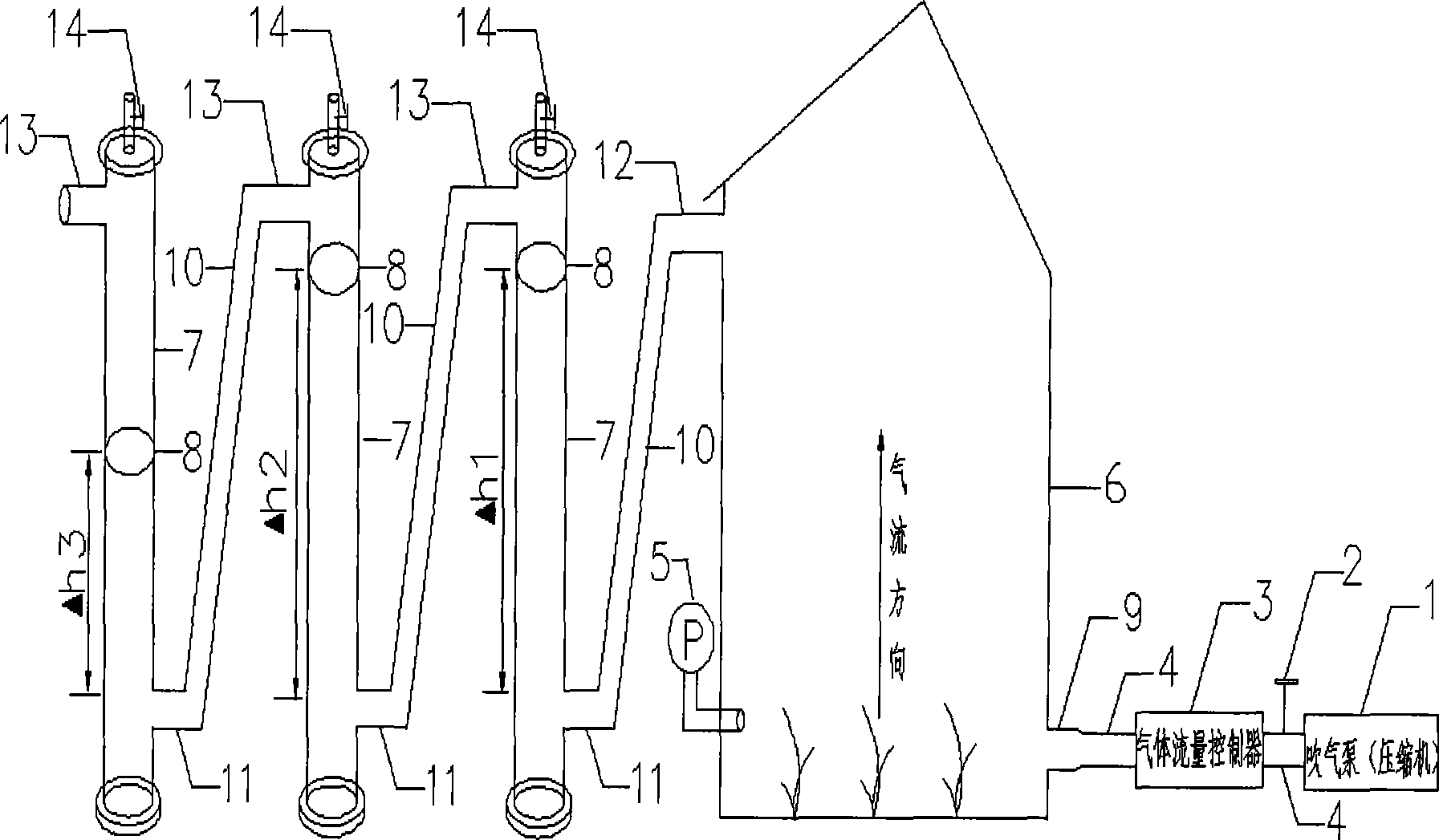

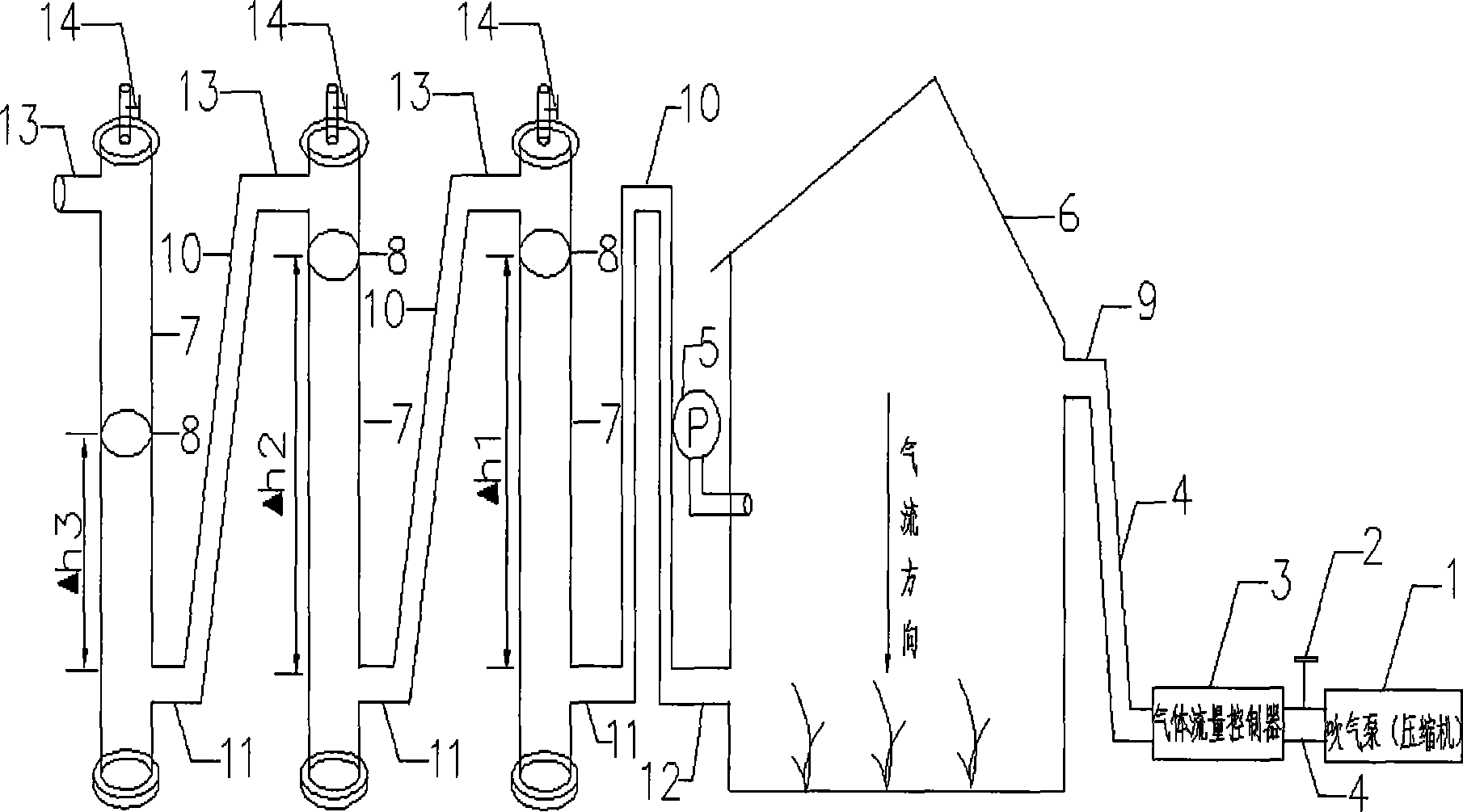

[0020] Embodiment 1 The technical solution of the present invention is a kind of high-pressure cultivation system, and this high-pressure cultivation system comprises at least one airtight cultivation chamber 6 or greenhouse, and described cultivation chamber 6 is communicated with a high-pressure gas source through air intake duct 4, and this The air pressure value provided by the high-pressure air source is about 1.5 times the air pressure value to be set in the cultivation room, and a gas flow controller for controlling the flow of high-pressure gas is installed between the high-pressure air source and the air intake pipe 4 3. An air valve 2 is connected to the air duct between the gas flow controller 3 and the high-pressure gas source; the cultivation chamber 6 is also connected with several pressure control pipes 7 for controlling the air pressure in the cultivation chamber 6 through the air outlet duct 10 In the pressure control tube 7, liquid for controlling the air pres...

Embodiment 2

[0021] Embodiment 2 On the basis of the foregoing embodiments, several pressure control tubes 7 are connected in series with each other through several air outlet and air guiding tubes 10 . In this way, the height of each pressure control tube 7 can be reduced by increasing the number of the pressure control tubes 7 connected in series.

Embodiment 3

[0022] Embodiment 3 On the basis of the foregoing embodiments, among the several air outlet air ducts 10, one end of one air outlet air duct 10 communicates with the upper or lower end 12 of the air outlet of the cultivation chamber, and the other end communicates with the air outlet of the cultivation chamber. The air inlet 11 of the pressure control pipe is connected, and the air outlet air pipe connected to the lower end of the cultivation chamber air outlet 12 at one end is an inverted U-shaped installation between the pressure control pipe 7 and the cultivation chamber 6. Outlet air duct 10 between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com