Preparation of nano spinelle lithium titanate

A lithium halite titanate and nano-tip technology, which is applied in the field of nanomaterials and new energy materials, can solve the problems of harsh reaction conditions and high energy consumption of the method, and achieve the effects of energy saving, simple reaction steps, and reduced reaction equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

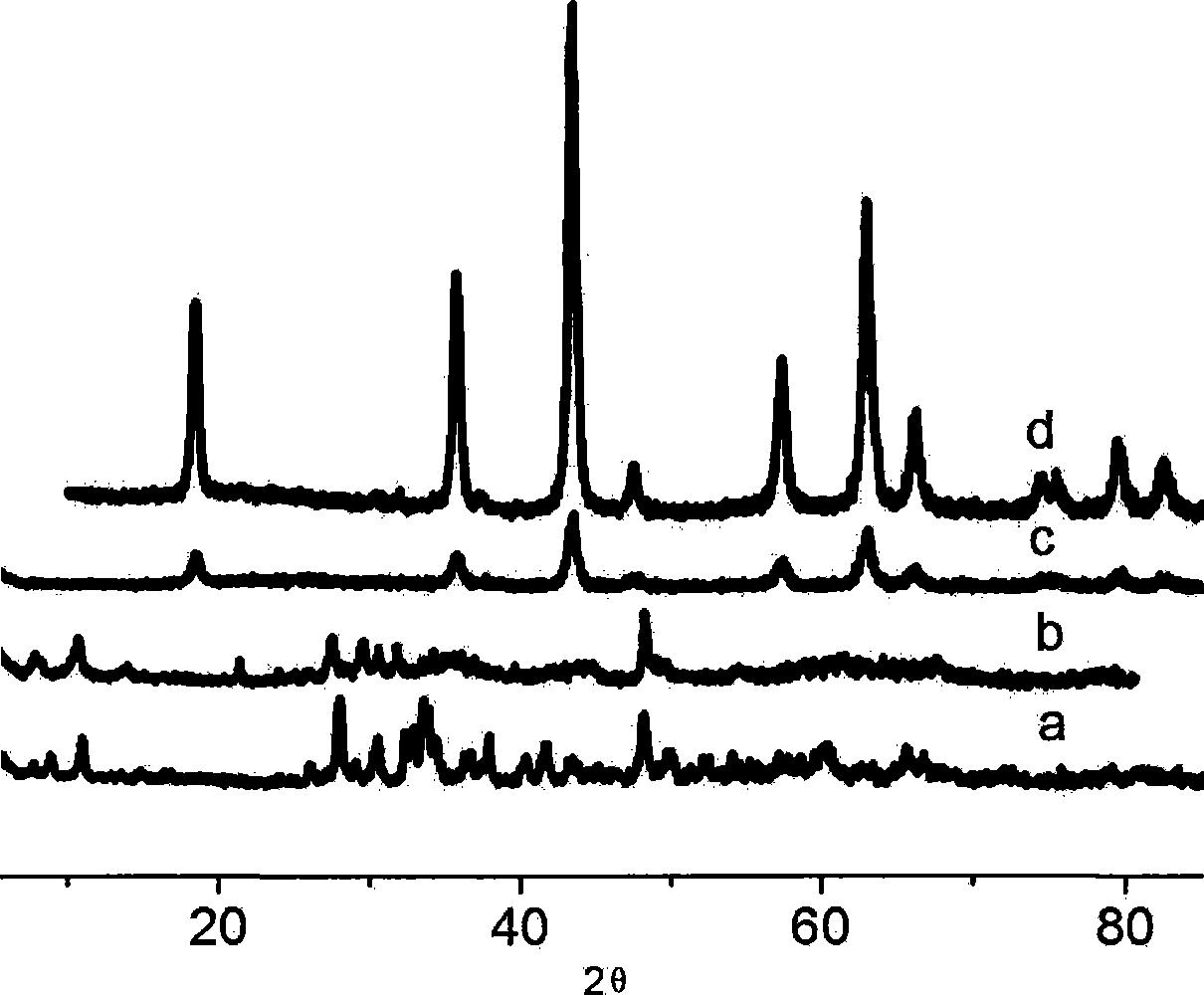

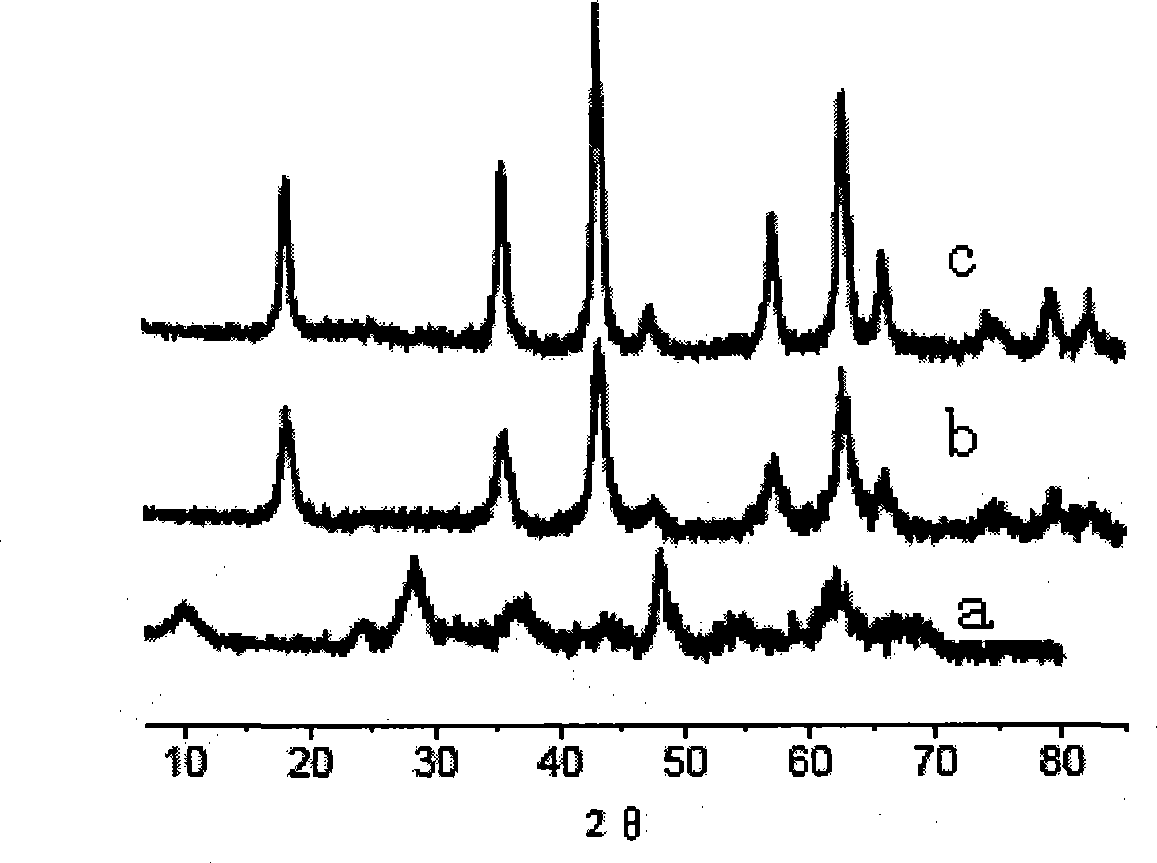

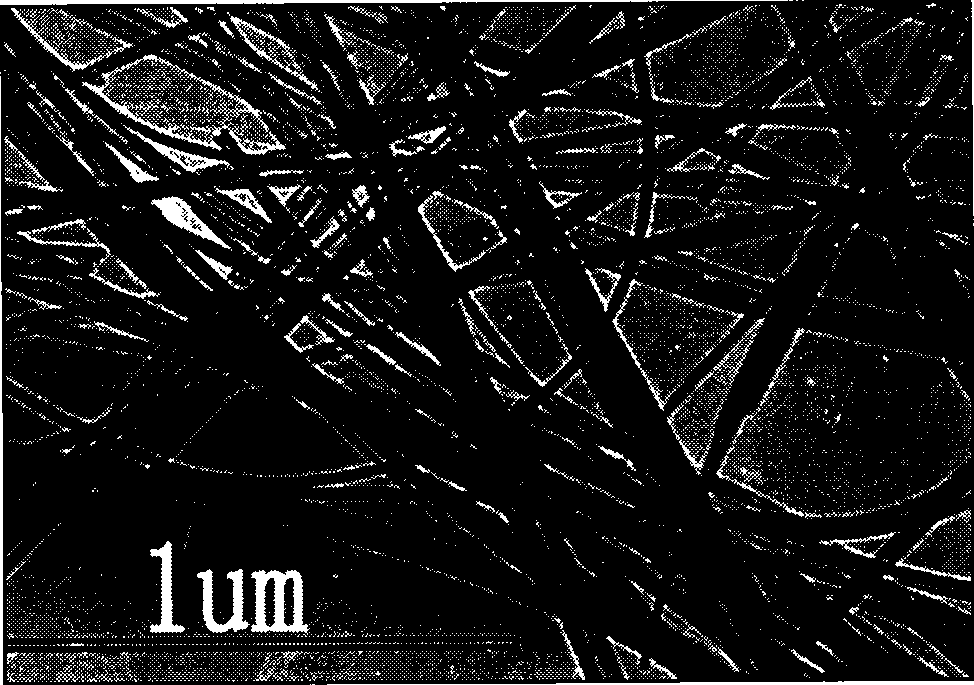

Embodiment 1

[0035] Take 3g of reagent grade anatase-type titanium dioxide, slowly add it into a polytetrafluoroethylene container containing 300ml of NaOH solution with a concentration of 10mol / L, control the temperature at 90°C, stir and reflux, react for 48 hours, cool down and filter, and use Neutralize the acid solution to pH = 1, filter and add to 5mol / L lithium hydroxide solution, stir at room temperature for 3 days (or react at 60°C for 10 hours), filter the product and calcinate at 300°C for 24 hours to obtain sharp Crystal lithium titanate.

Embodiment 2

[0037] Get 3g titanium dioxide (Degussa produces P 25 ), adding 300ml of NaOH solution with a concentration of 12mol / L into a polytetrafluoroethylene container, controlling the temperature at 130°C, reflux and stirring for 48 hours, cooling and filtering, washing the product with water to pH=13.5, and adding to 0.5 mol / L lithium acetate solution, stirred for 3 hours, filtered the product and calcined at 1000°C for 2 hours to obtain spinel lithium titanate.

Embodiment 3

[0039] Get 3g titanium dioxide (Degussa produces P 25 ), slowly added to the polytetrafluoroethylene container containing 300ml of NaOH solution with a concentration of 10mol / L, controlled the temperature at 130°C, stirred and refluxed, reacted for 24 hours, cooled and filtered, washed the product with water to pH=13, added after filtration into a 1 mol / L lithium hydroxide solution, stirred for 10 hours, filtered and calcined at 500°C for 6 hours to obtain a spinel lithium titanate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com