Iron runner ramming mass

A technology of ramming material and molten iron ditch, applied in the direction of discharge device, etc., can solve the problems of pollution, increase the environment, pollute the environment, etc., and achieve the effect of reducing the source of environmental pollution, increasing the number of jobs, and having good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

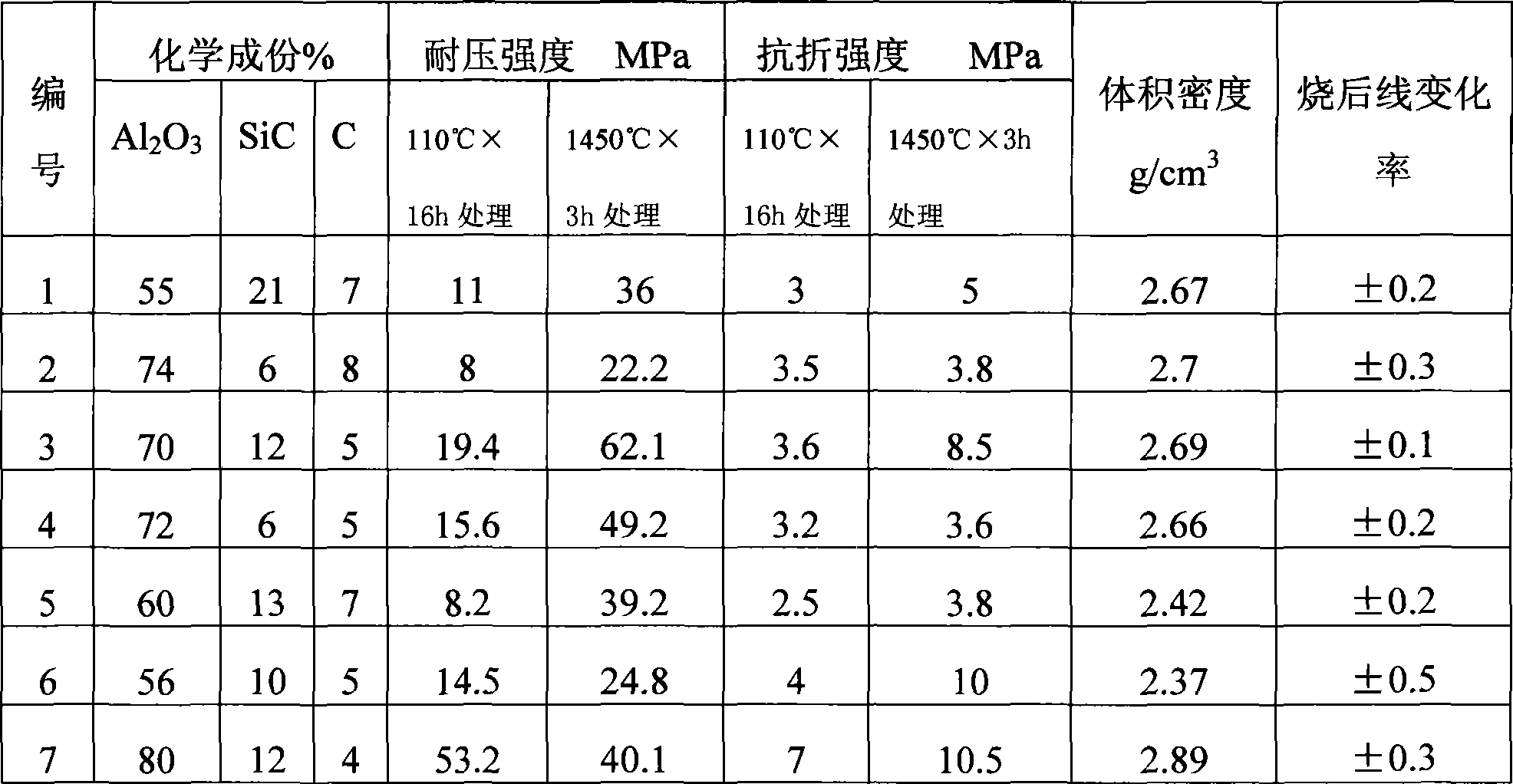

Image

Examples

Embodiment 1

[0029] Composition and content of iron water ditch ramming material:

[0030] Component Content (percentage)

[0031] Aggregate 8-5mm 15%

[0032] 5-3mm 21%

[0033] 3-1mm 21%

[0034] 1-0mm 5%

[0035] 70 Bauxite 1-0mm 5%

[0036] Recycled fine powder 325 mesh 6%

[0037] SiC40-70% 1-0mm 5%

[0038] SiC40-70% 325 mesh 13%

[0039] Metal silicon powder 200 mesh 2%

[0040] Oxalic acid 1%

[0041] Aluminum sulfate solution density 1.2-1.3g / cm3 6%

[0042] Weigh the graphite, metal silicon, SiC, bauxite clinker powder, and recycled material powder in the above formula according to their content, add oxalic acid, stir with roller for 15-20 minutes, add half of the amount of aluminum sulfate above, and stir with roller 8-10 minutes, stuffing for 16-20 hours, stirring with rolling wheel for 8-10 minutes, adding the remaining aluminum sulfate, stirring evenly for 10-12 minutes, the finished product is packaged.

Embodiment 2

[0044] Component Content

[0045] Aggregate 8-5mm 11%

[0046] 5-3mm 18%

[0047] 3-1mm 18%

[0048] 1-0mm 10%

[0049] 70 Bauxite 1-0mm 12%

[0050] Recycled fine powder 325 mesh 6%

[0051] SiC40-70% 1-0mm 5%

[0052] SiC40-70% 325 mesh 10%

[0053] Metal silicon powder 200 mesh 1%

[0054] Oxalic acid 1%

[0055] Aluminum sulfate solution density 1.2-1.3g / cm3 8%

[0056] Weigh the graphite, metal silicon, SiC, bauxite clinker powder, and recycled material powder in the above formula according to their content, add oxalic acid, stir with roller for 15-20 minutes, add half of the amount of aluminum sulfate above, and stir with roller 8-10 minutes, stuffing for 16-20 hours, stirring with rolling wheel for 8-10 minutes, adding the remaining aluminum sulfate, stirring evenly for 10-12 minutes, the finished product is packaged.

[0057] The production method of above-mentioned aggregate comprises the following steps:

[0058] 1) Recycling the waste discharged from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com