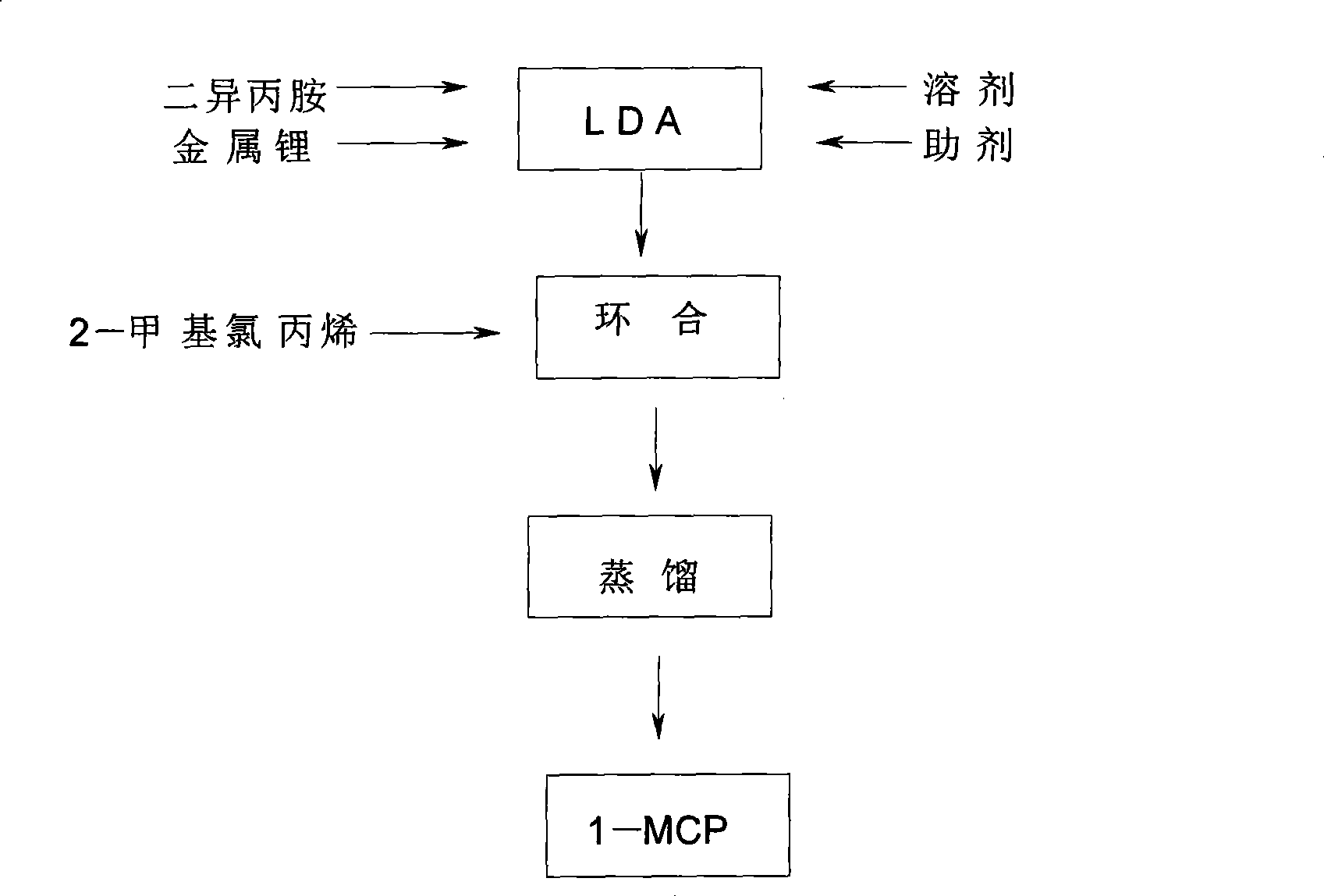

Use of lithium diisopropyl amido in 1-methyl cyclopropene preparation

A technology of methylcyclopropene and diisopropylamino, applied in the field of chemical synthesis, can solve the problems such as the application of lithium diisopropylamide which has not been reported, achieves reduction of production cost, and solves the problems of high energy consumption and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

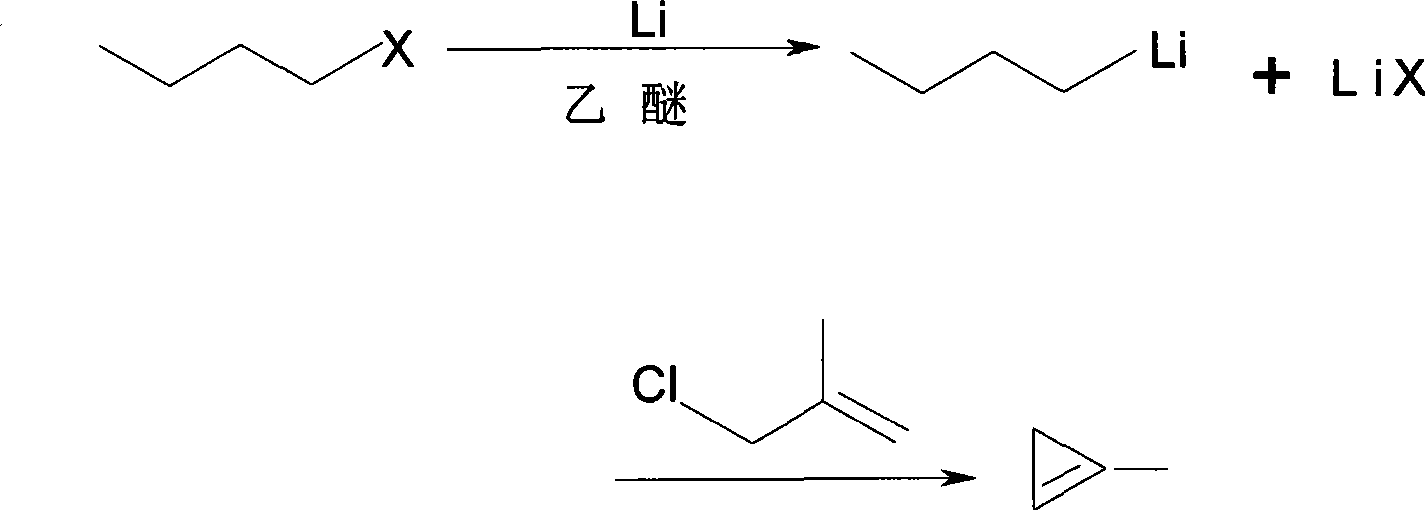

Method used

Image

Examples

Embodiment 1

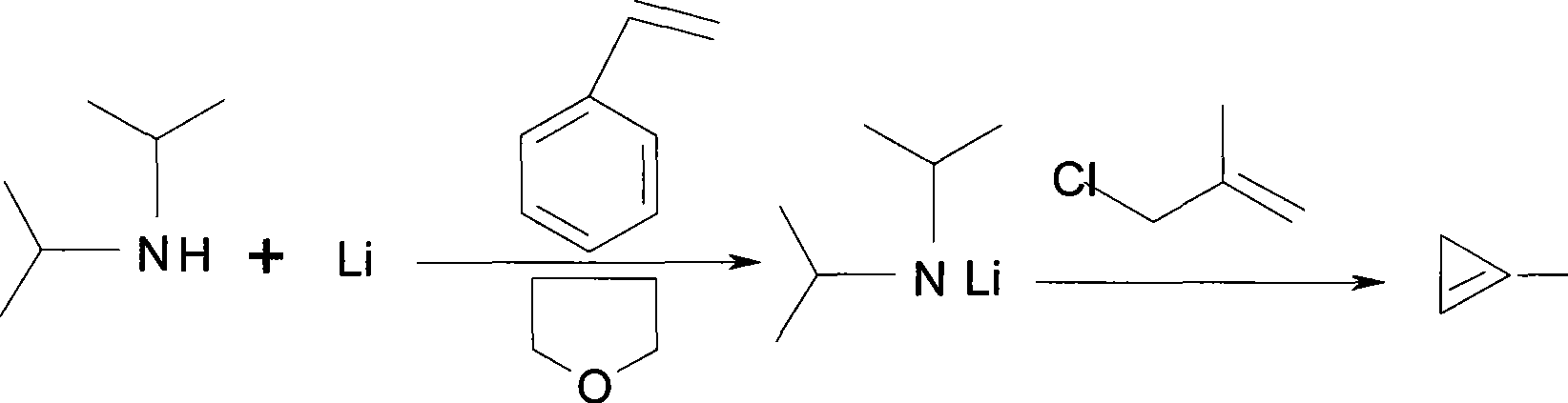

[0022] Embodiment 1: Preparation lithium diisopropylamide

[0023] Add 170g of diisopropylamine and 12g of metal lithium into 300ml of tetrahydrofuran, and slowly add 95g of styrene dropwise at 37°C. As the drop continues, the reaction system begins to heat up, and the temperature rises to 56°C. At this time, the reaction system is gray. Afterwards, the temperature was lowered, and the temperature was kept constant at 37°C. Stirring was continued, and lithium diisopropylamide was formed after 6 hours of reaction.

Embodiment 2

[0026] Embodiment 2: Preparation lithium diisopropylamide

[0027] Add 170g of diisopropylamine and 12g of metal lithium into 300ml of anhydrous ether. At 37°C, slowly add 95g of tetramethylethylenediamine dropwise. As the addition continues, the temperature of the reaction system begins to rise to 56°C. At this time, the reaction system was gray, and then began to lower the temperature, kept at 37°C, and continued to stir. After 4 hours of reaction, lithium diisopropylamide was formed.

Embodiment 3

[0030] Embodiment 3: Preparation lithium diisopropylamide

[0031] Add 180g of diisopropylamine and 10g of lithium metal into 350ml of tetrahydrofuran. At 20°C, slowly add 105g of styrene dropwise. As the addition continues, the reaction system begins to heat up to 45°C. At this time, the reaction system is gray. Afterwards, start to lower the temperature, keep 20°C, continue to stir, and generate lithium diisopropylamide after reacting for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com