Major-minor cylinder combined engine

A technology of engine and auxiliary cylinder, which is applied in the field of combined engine of main and auxiliary cylinders, can solve the problems that the thermal energy efficiency is far from the theoretical value, it is difficult to achieve complete combustion of fuel, and the emission of harmful substances is large, so as to improve the effective thermal efficiency and reduce the manufacturing cost , the effect of less pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

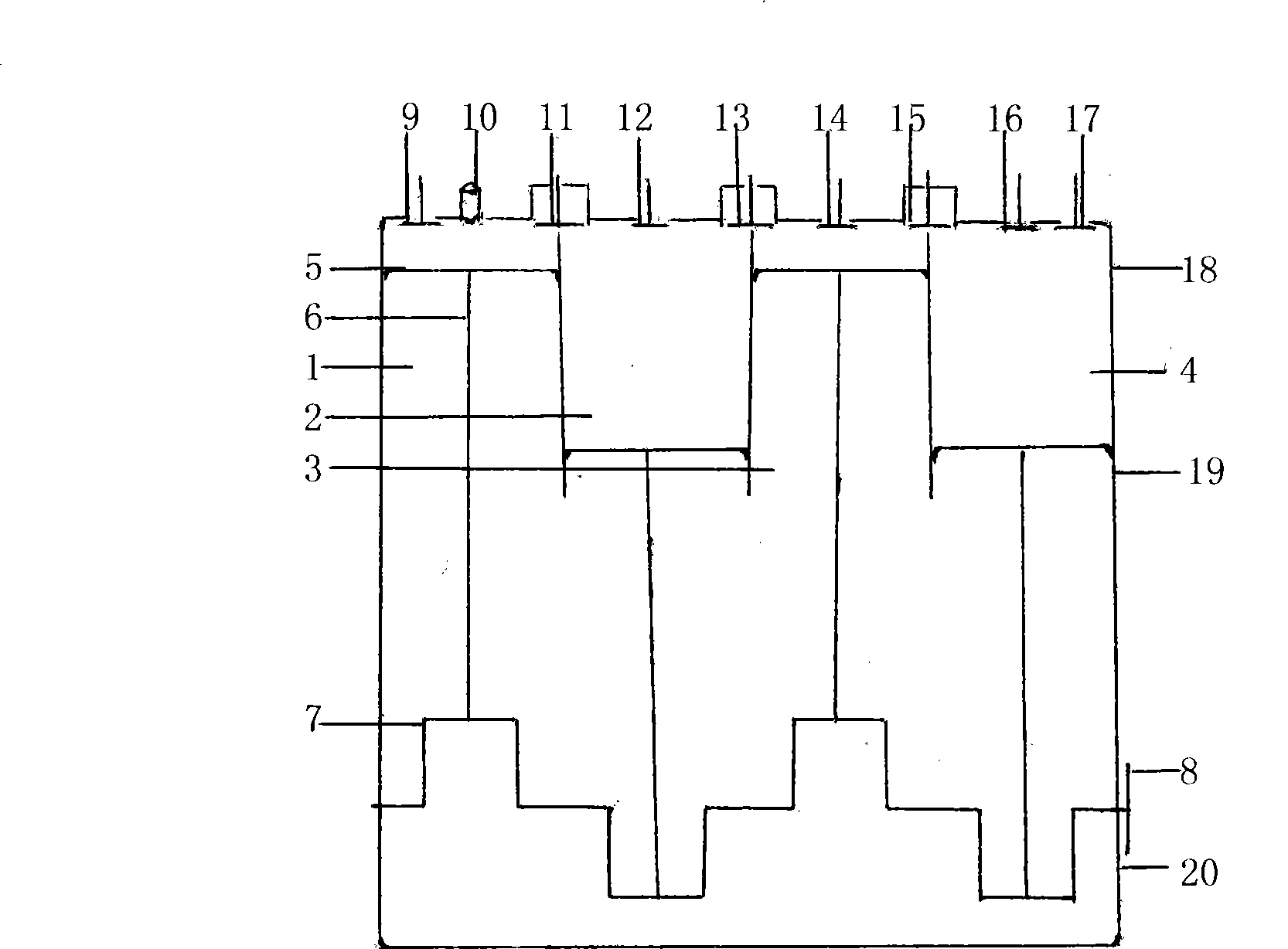

[0017] The combined main and auxiliary cylinder engine of the present invention consists of a cylinder body 19, a cylinder cap 18, an oil pan 20, a master cylinder 1, a first auxiliary cylinder 2, a second auxiliary cylinder 3, a third auxiliary cylinder 4, a piston 5, and a connecting rod 6 , crankshaft 7, main cylinder intake valve 9, spark plug or diesel high-pressure injector 10, main cylinder 1 and first auxiliary cylinder 2 upper exhaust intake valve 11, first auxiliary cylinder 2 intake valve 12, first auxiliary cylinder Exhaust intake valve 13 on cylinder 2 and the upper part of the second auxiliary cylinder 3, intake valve 14 on the second auxiliary cylinder 3, exhaust intake valve 15 on the upper part of the second auxiliary cylinder 3 and third auxiliary cylinder 4, third auxiliary cylinder 4 Intake valve 16, third secondary cylinder 4 exhaust valve 17, flywheel 8 and other components. The cylinder cap 18 seals the upper part of the cylinder body 19, the oil pan 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com