Low-resistance and low-NOx rotational flow coal powder burner with divergent segment

A technology of swirling pulverized coal and gradually expanding section, which is applied to burners, burners, combustion methods and other directions of burning powder fuels, can solve the problems of boilers unable to operate at full load, low concentration and thin separation efficiency, and reduced coal mill output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

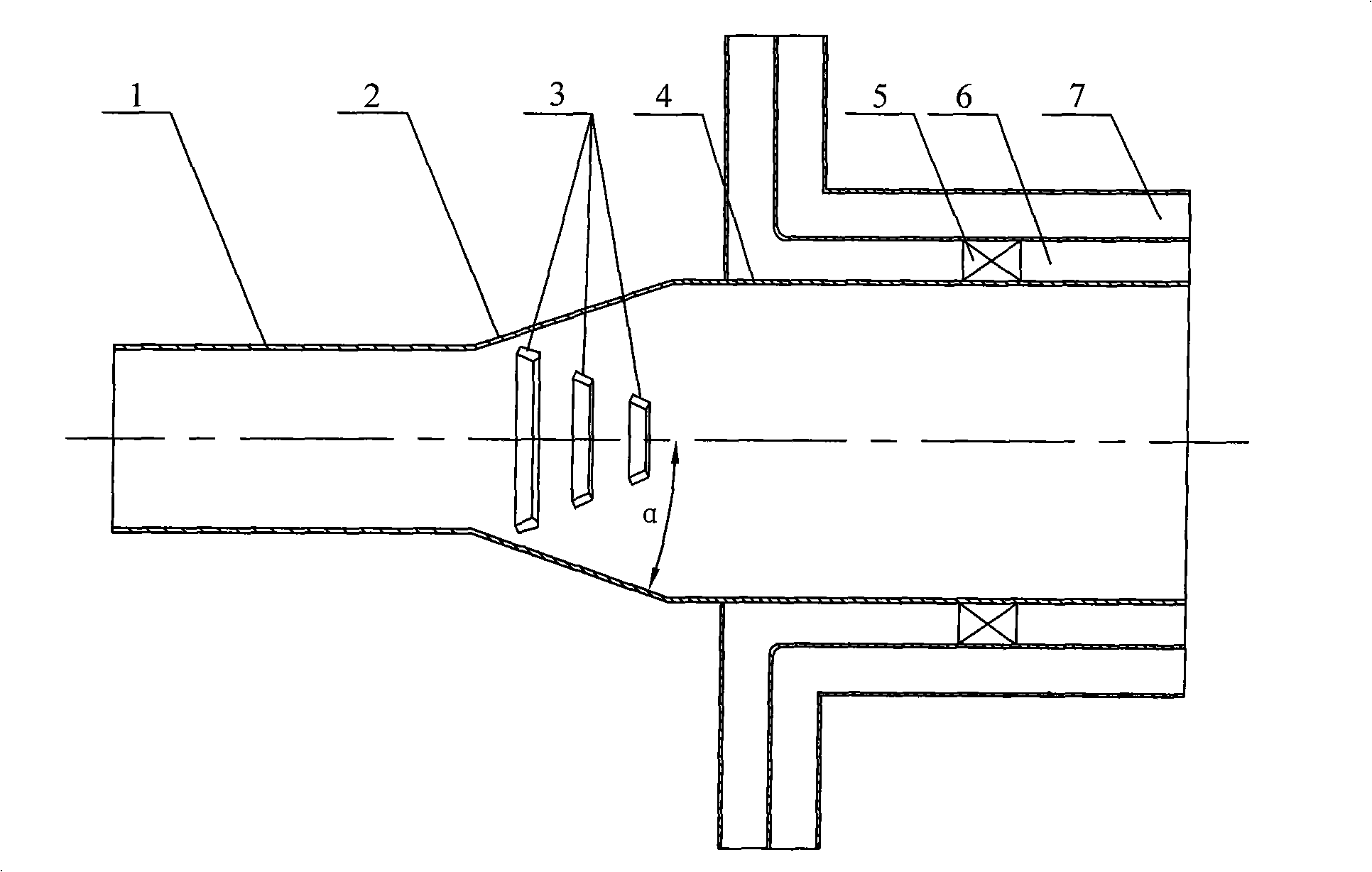

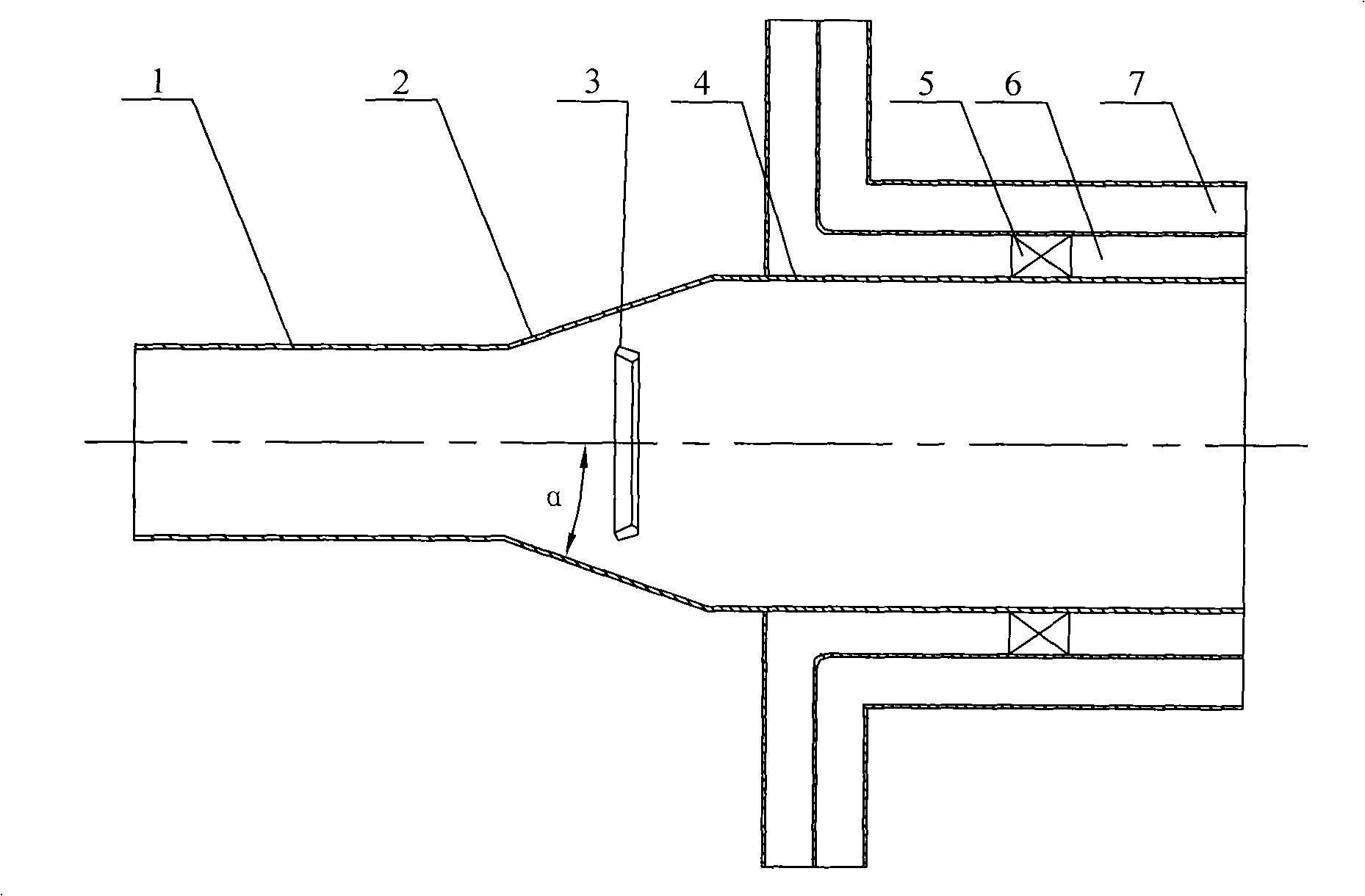

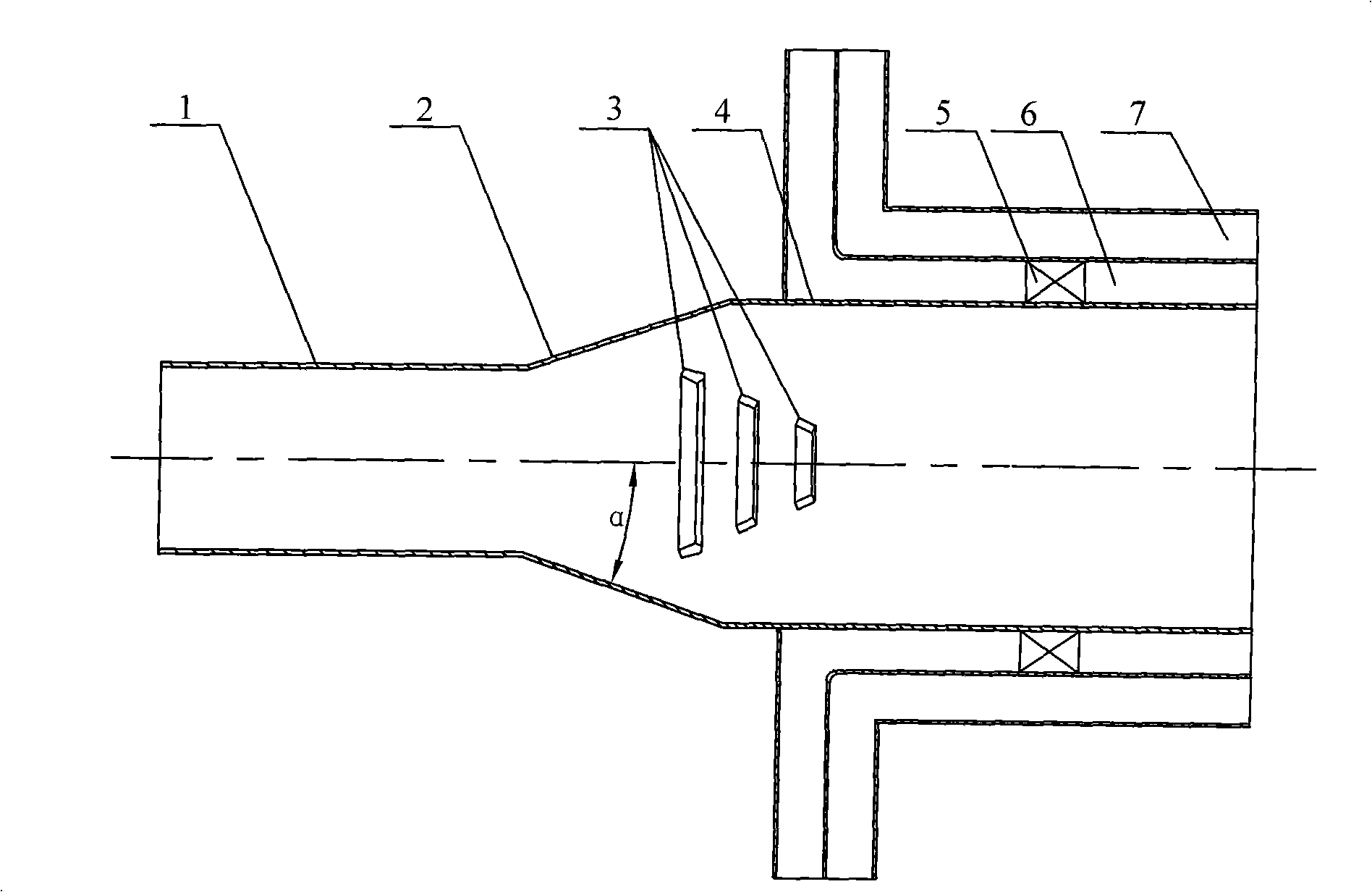

[0006] Specific implementation mode one: combine figure 1 and figure 2 This embodiment is described. This embodiment includes a primary air duct, at least one frustum-shaped separating ring 3, an inner swirler 5, an inner secondary air duct 6 and an outer secondary air duct 7. The primary air duct consists of a primary The air duct inlet straight pipe section 1, the primary air duct gradual expansion section 2 and the primary air duct outlet straight pipe section 4 are composed of the air inlet end of the primary air duct gradual expansion section 2 and the air outlet end of the primary air duct inlet straight pipe section 1 Then, the air outlet end of the primary air duct gradual expansion section 2 is fixedly connected with the air inlet end of the primary air duct outlet straight pipe section 4, and the at least one frustum-shaped separation ring 3 is arranged in the primary air duct gradual expansion section 2, The small-diameter end of the frustum-shaped separation ring...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 To describe this embodiment, the included angle between the primary air channel diverging section 2 and the central axis of the primary air channel in this embodiment is α, 90°>α>0°. Such setting can ensure that a dense coal powder area is formed near the center of the air outlet section of the straight pipe section 4 at the outlet of the primary air duct, and a light coal powder area is formed near the pipe wall area, and more effectively ensures that the primary wind resistance is low. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation mode three: combination figure 1 Describe this embodiment, the primary air duct inlet straight pipe section 1, the primary air duct gradual expansion section 2, the frustum-shaped separation ring 3, the primary air duct outlet straight pipe section 4, the inner secondary air duct 6 and the outer secondary air duct in this embodiment. Wind duct 7 is coaxially arranged. Such setting is beneficial to the passage of primary wind and secondary wind. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com