Method for recovery of lipase activity

A recovery method, lipase technology, applied in the directions of microorganism-based methods, fatty acid esterification, biochemical equipment and methods, etc., can solve problems such as decreased lipase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) 1 Kg of Lipozyme TL-IM (average particle size 800 μm) produced by Novozymes A / S Company was pulverized at 17600 rpm using a steel pin mill (Fine impact mill 100 UPZ) produced by Hosokawa Micron Corporation. The particle size of the crushed lipase was measured with a particle size distribution analyzer LA-500 manufactured by Horiba Manufacturing Co., Ltd., and the average particle size was 13.8 μm. 1 kg of cellulose powder (Nippon Paper Chemicals Co., Ltd: average particle size 30 μm) as a filter aid was added to the powder to prepare a lipase powder composition.

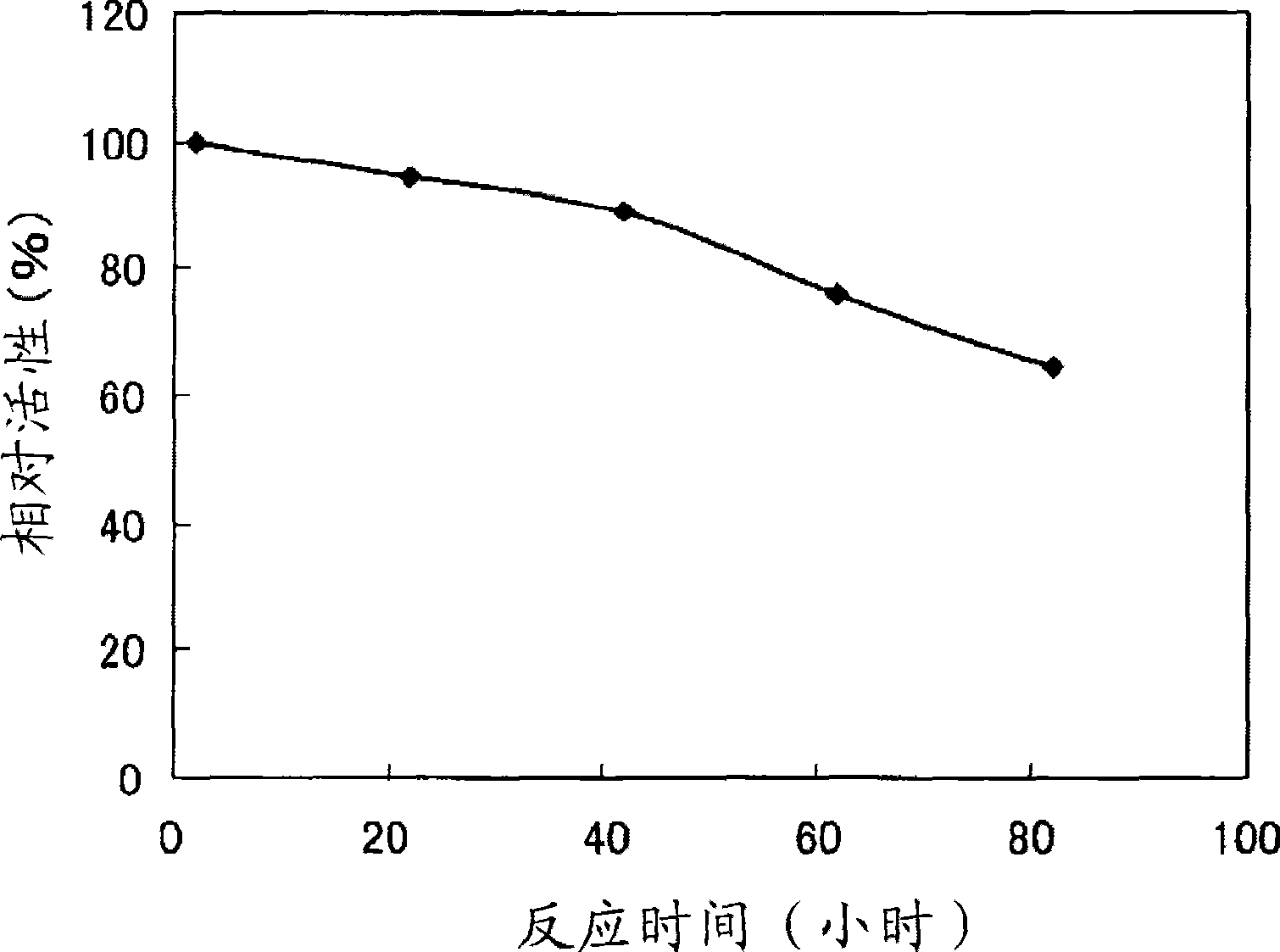

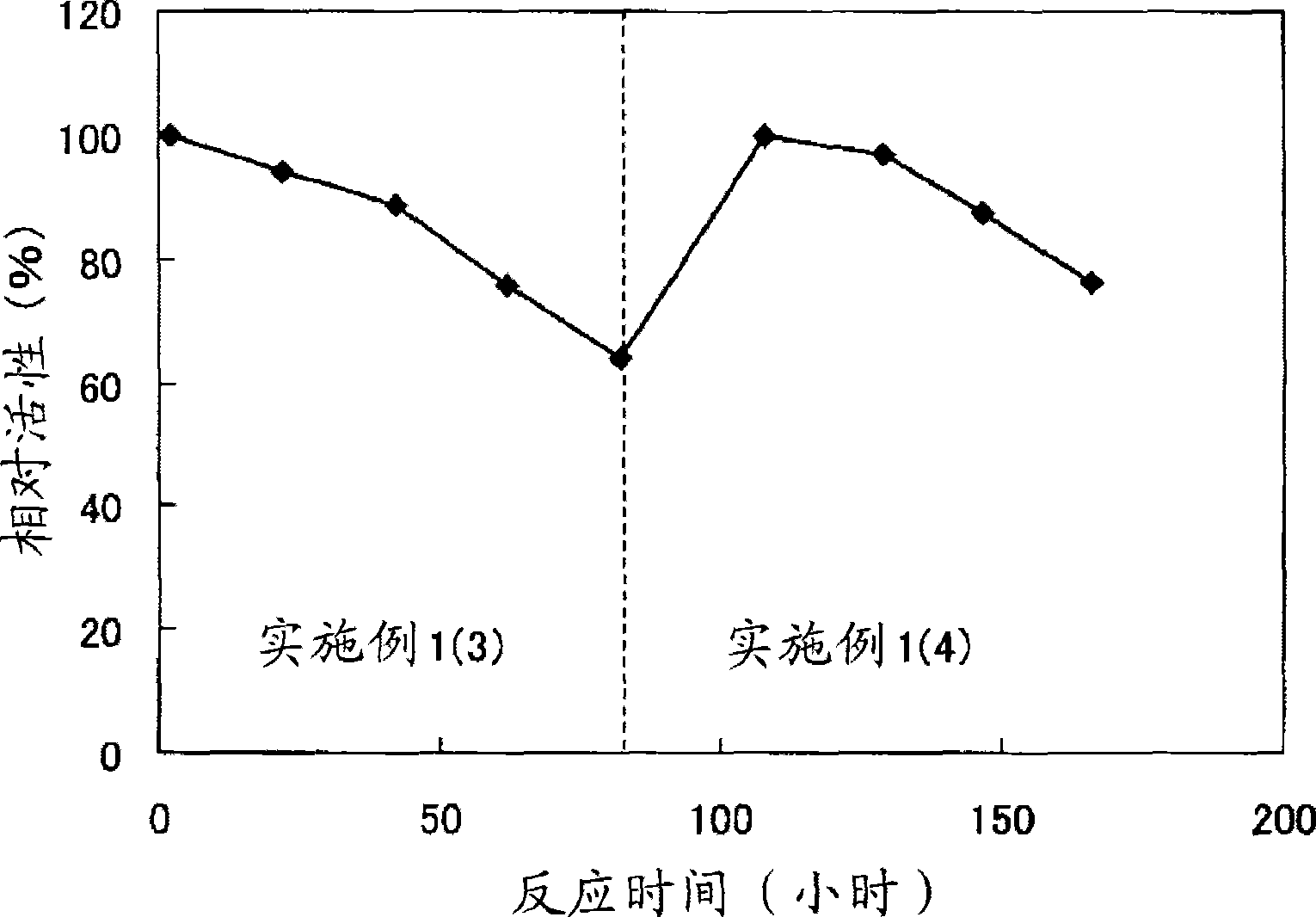

[0047] (2) Add 90 g of rapeseed decolorizing oil and 10 g of ODO (manufactured by Nisshin Oleo Group Co., Ltd.: medium-chain fatty acid triglycerides) to 5 g of the lipase composition obtained in this way, stir at room temperature for 24 hours, and filter Recover the lipase composition. The transesterification activity of the lipase composition was measured by the following method. When the activity of Lipozym...

Embodiment 2

[0059] (2-1) To 5g of the lipase composition obtained in (1) of Example 1, 90g of rapeseed decolorizing oil and 10g of ODO (manufactured by Nisshin Oriyo Group Co., Ltd.) were added and stirred at 60°C for 2 hours , Filter and recover the lipase composition. The transesterification activity of the lipase composition was measured by the same method as in Example 1, and its relative activity was 557.

[0060] (2-2) Add 1.2% by mass of the lipase composition obtained in (2-1) above to 100 g of soybean oil and 25 g of extremely hardened soybean oil (manufactured by Hengsen Oil Industry Co., Ltd.), and react at 70°C After 120 hours, the lipase composition was recovered by filtration. In the same manner as in Example 1, the lipase activity (2-2a) of a part of the recovered lipase composition was measured. Disperse the previously recovered lipase composition in acetone. After filtering, the filter residue is recovered and dispersed in 50 g of rapeseed decolorizing oil: ODO (manufactured ...

Embodiment 3

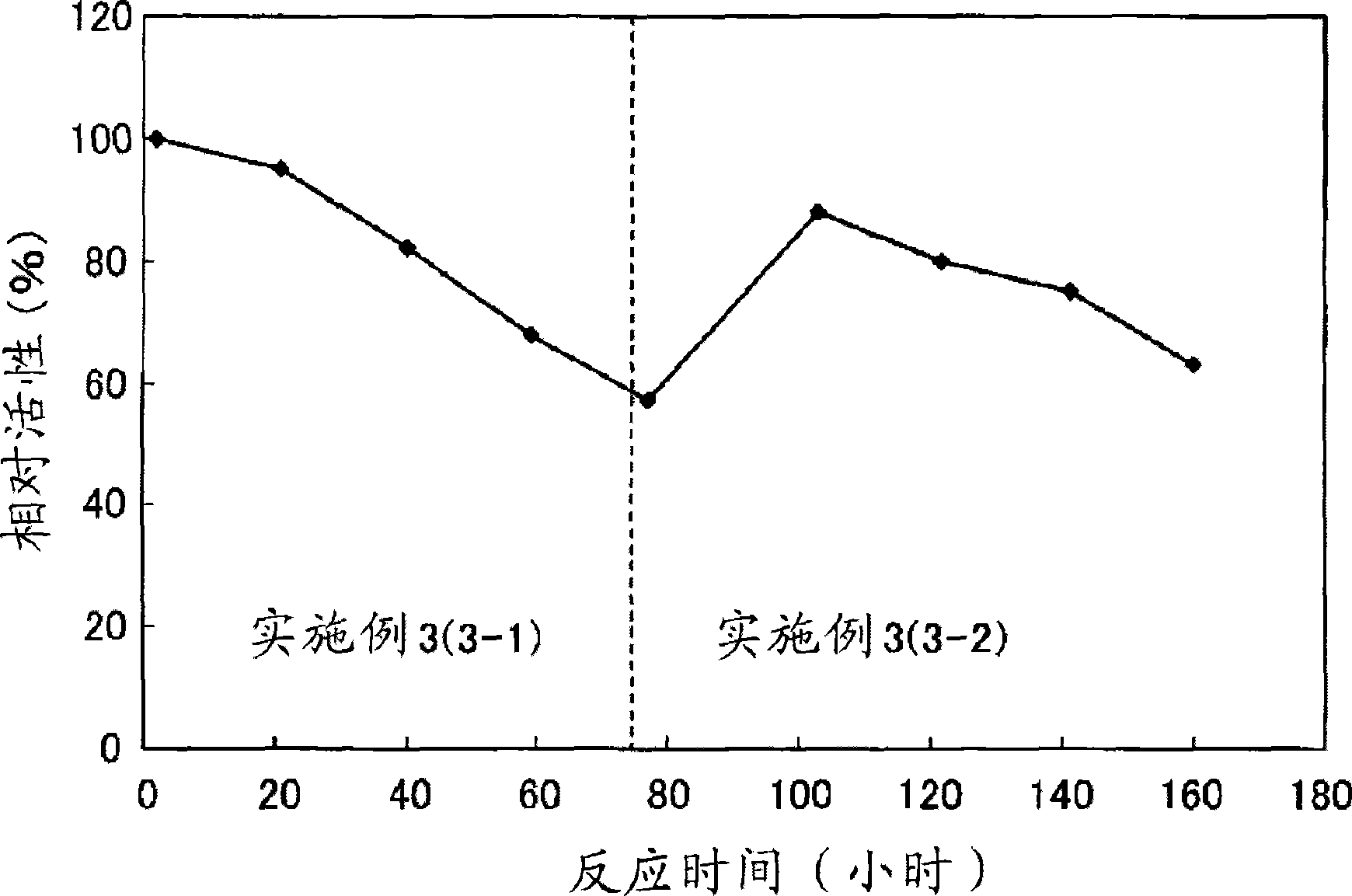

[0064] Add 5% by mass of Lipozyme TL-IM (immobilized lipase: Novozymes) to 85 g of rapeseed decolorizing oil (manufactured by Nissin Oriyo Group Co., Ltd.) and 15 g ODO (manufactured by Nissin Orion Group Co., Ltd.) Produced by A / S Company), stirred at 60°C for 19 hours to carry out the transesterification reaction. The transesterification rate over time was determined, and the progress of the reaction was confirmed. In the transesterification reaction, gas chromatography was used to analyze the glyceride composition, and the ratio of the transesterification reactant in the measurement sample was calculated by calculation.

[0065] The above-mentioned immobilized lipase after the reaction is filtered and recovered, and the recovered immobilized lipase is repeatedly used in the transesterification reaction. Repeat the reaction several times, confirm the change of the reaction rate by the relative ratio, and show it in image 3 (3-1).

[0066] The above-mentioned immobilized lipase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com