Solder ball printing device

A technology for printing devices and solder balls, which is applied to tin feeding devices, auxiliary devices, assembling printed circuits with electrical components, etc., can solve the problems of increased production tact, increased cost of bump formation, and poor productivity, and improved operating efficiency. , The effect of improving filling efficiency and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

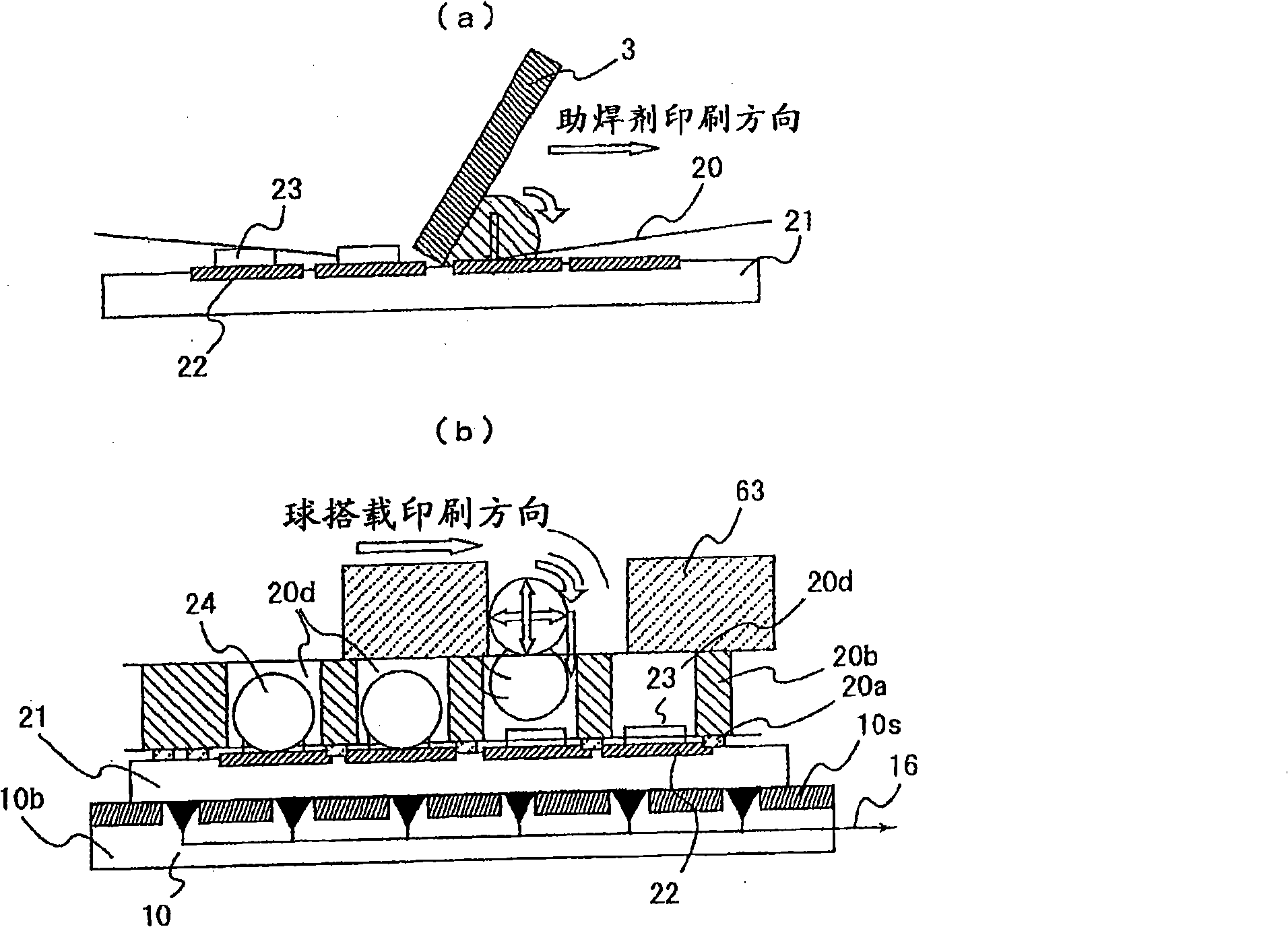

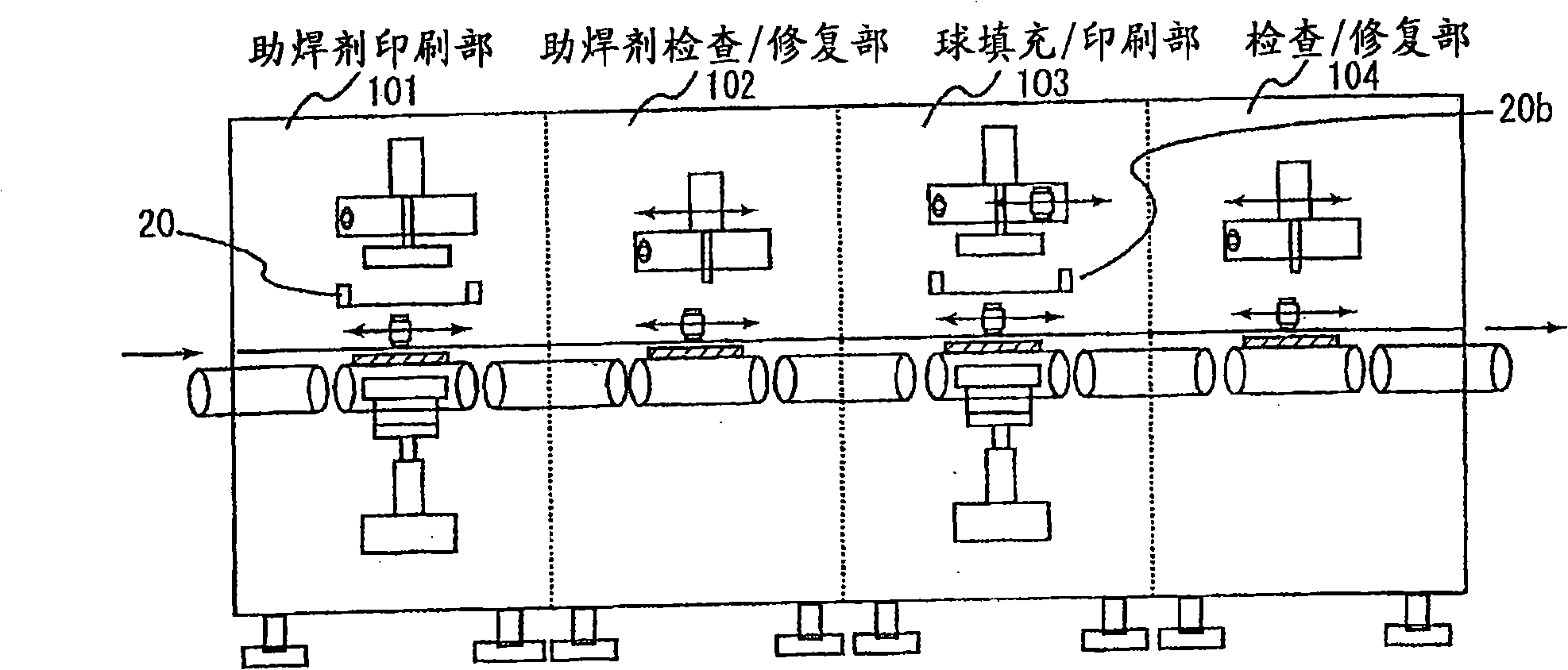

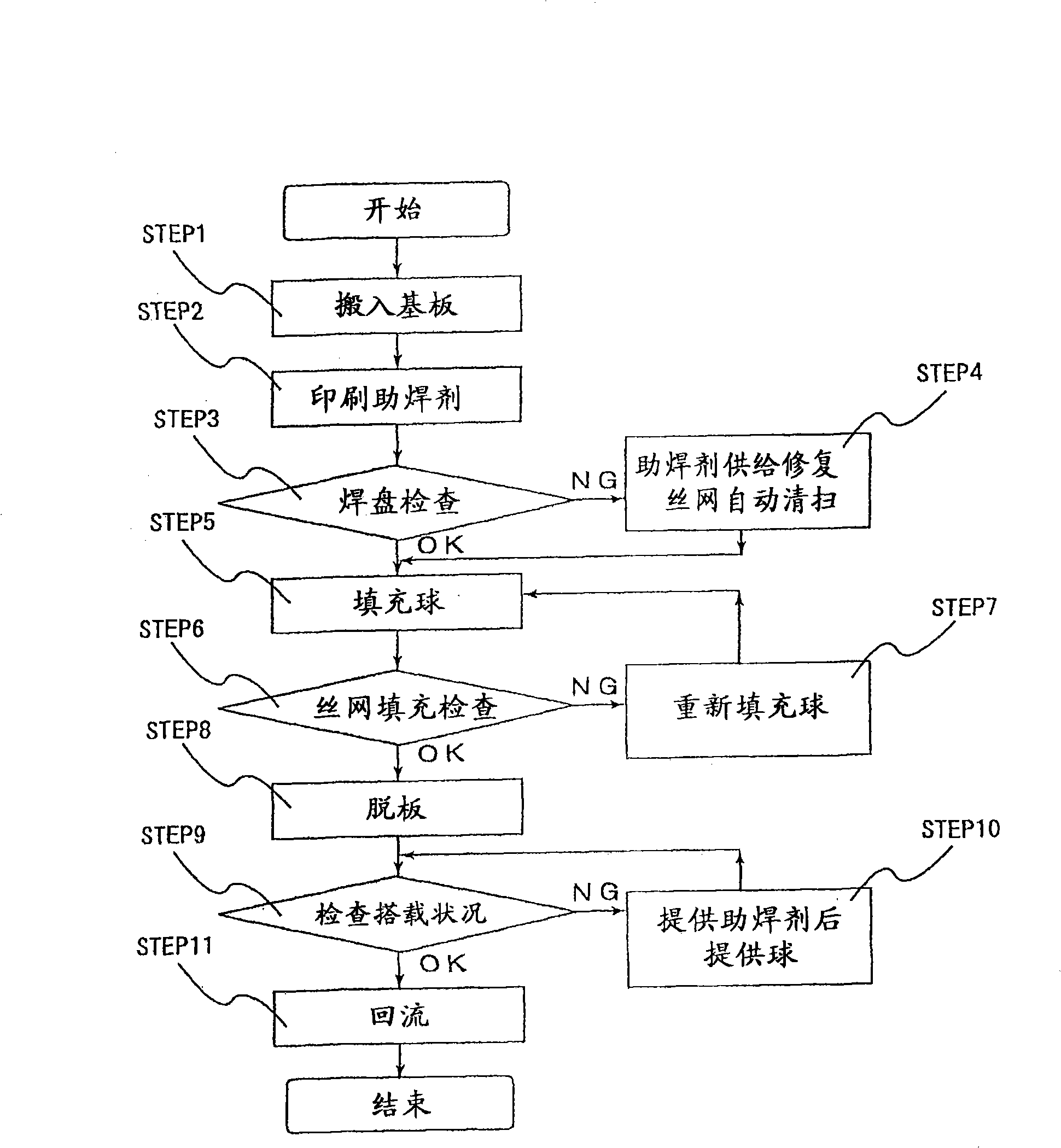

[0037] Hereinafter, preferred embodiments of the printing apparatus and the bump forming method of the present invention will be described with reference to the drawings. figure 1 Shows the outline of the printing process in the flux printing section and the solder ball filling / printing section. figure 1 (a) shows the flux printing process, and (b) shows the state of solder ball filling / printing.

[0038] exist figure 1 In (a), flux is placed on the flux printing screen 20 provided with an opening corresponding to the position and shape of the electrode pad 22 previously provided on the substrate 21, and the squeegee 3 is moved. A predetermined amount of flux 23 is printed on the electrode pads 22 of the substrate 21 .

[0039] In this embodiment, the screen 20 is a screen for flux printing, and a metal screen produced by an additive method is used so that high-precision pattern position accuracy can be ensured. As the scraper 3, any one of a square scraper, a sword scraper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com