Two-body type base semiconductor laser

A technology of semiconductors and lasers, applied in the field of lasers, can solve the problems of large tracking errors of lasers, degradation of optical isolation of lasers, and high assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

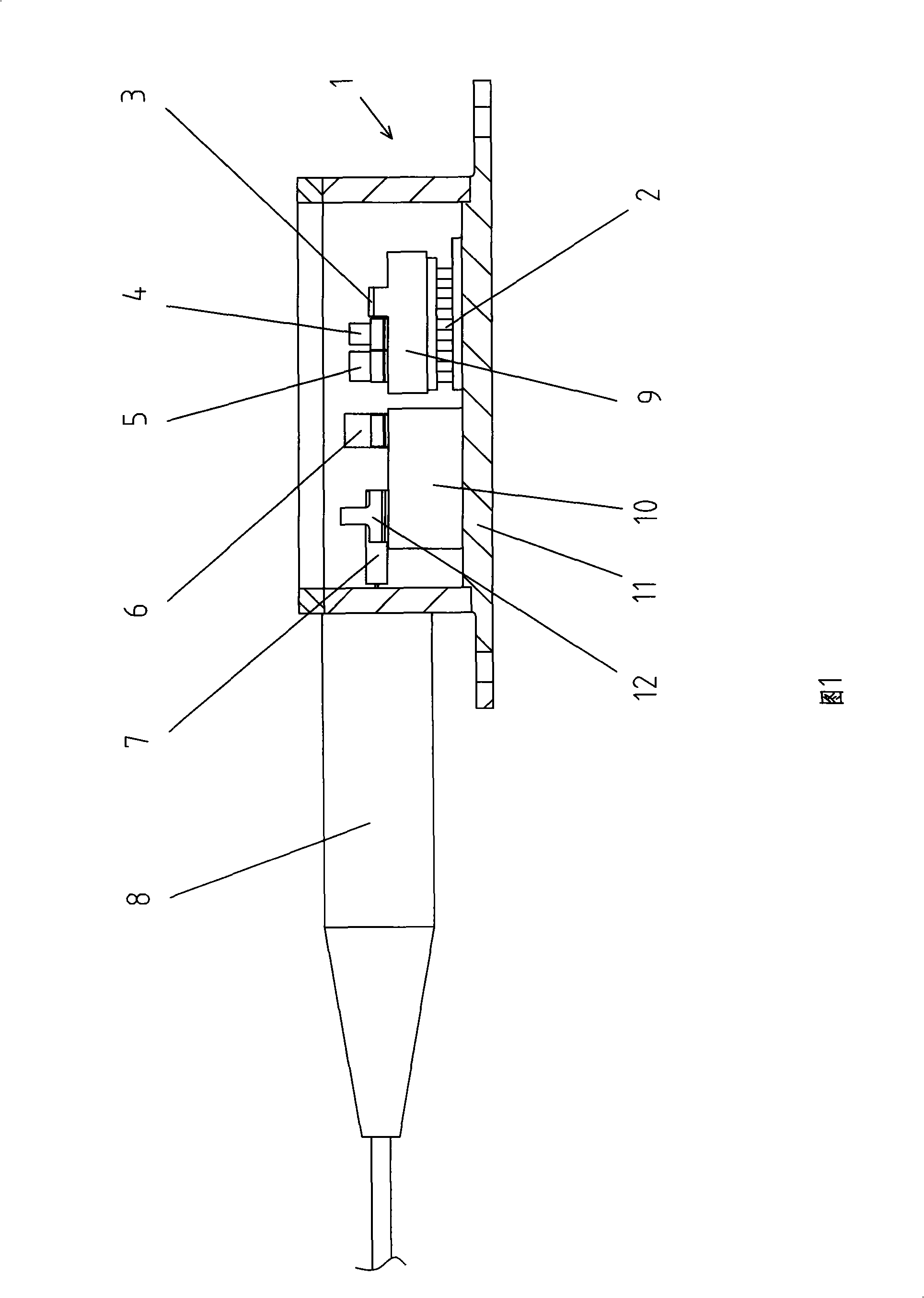

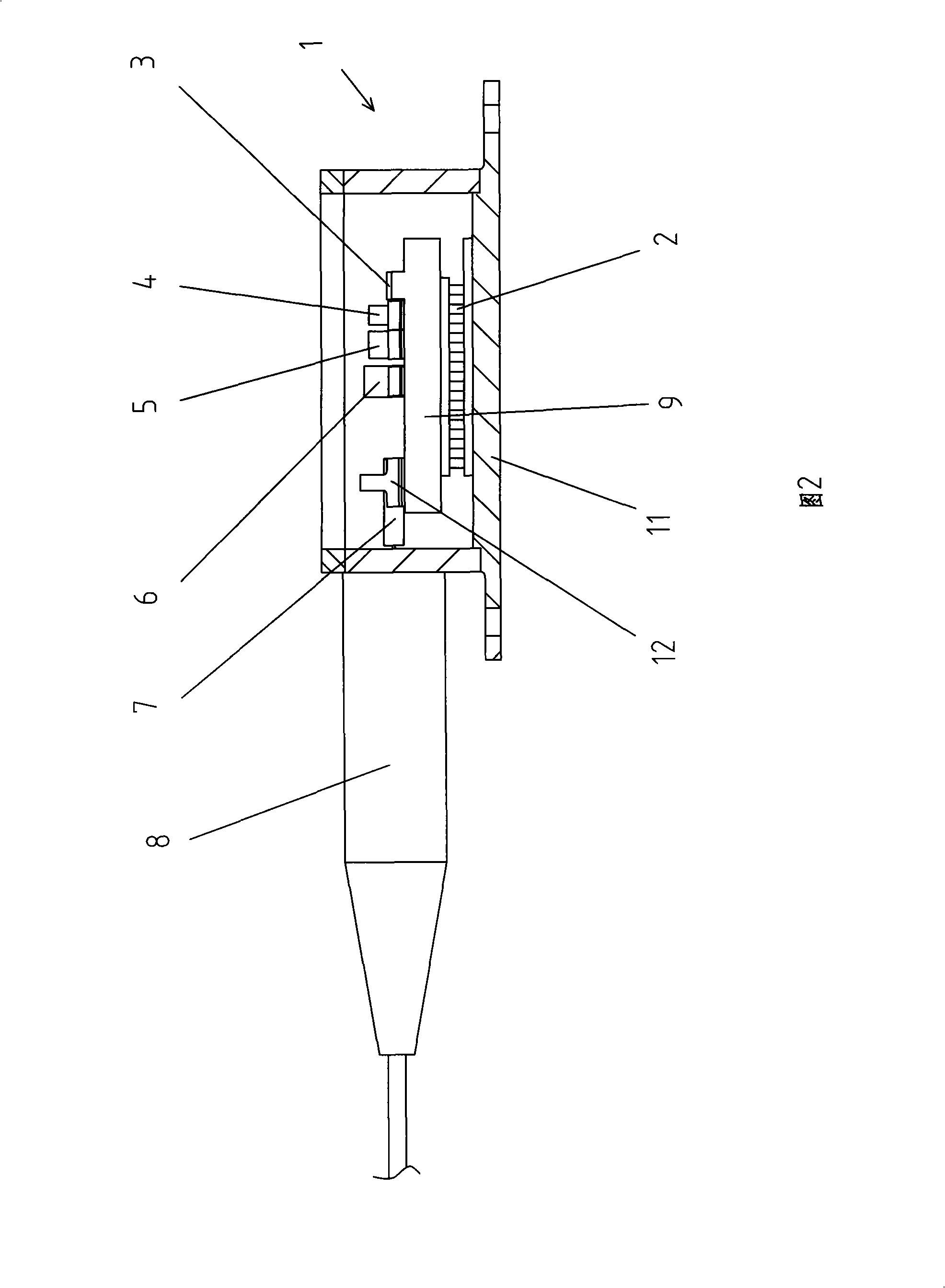

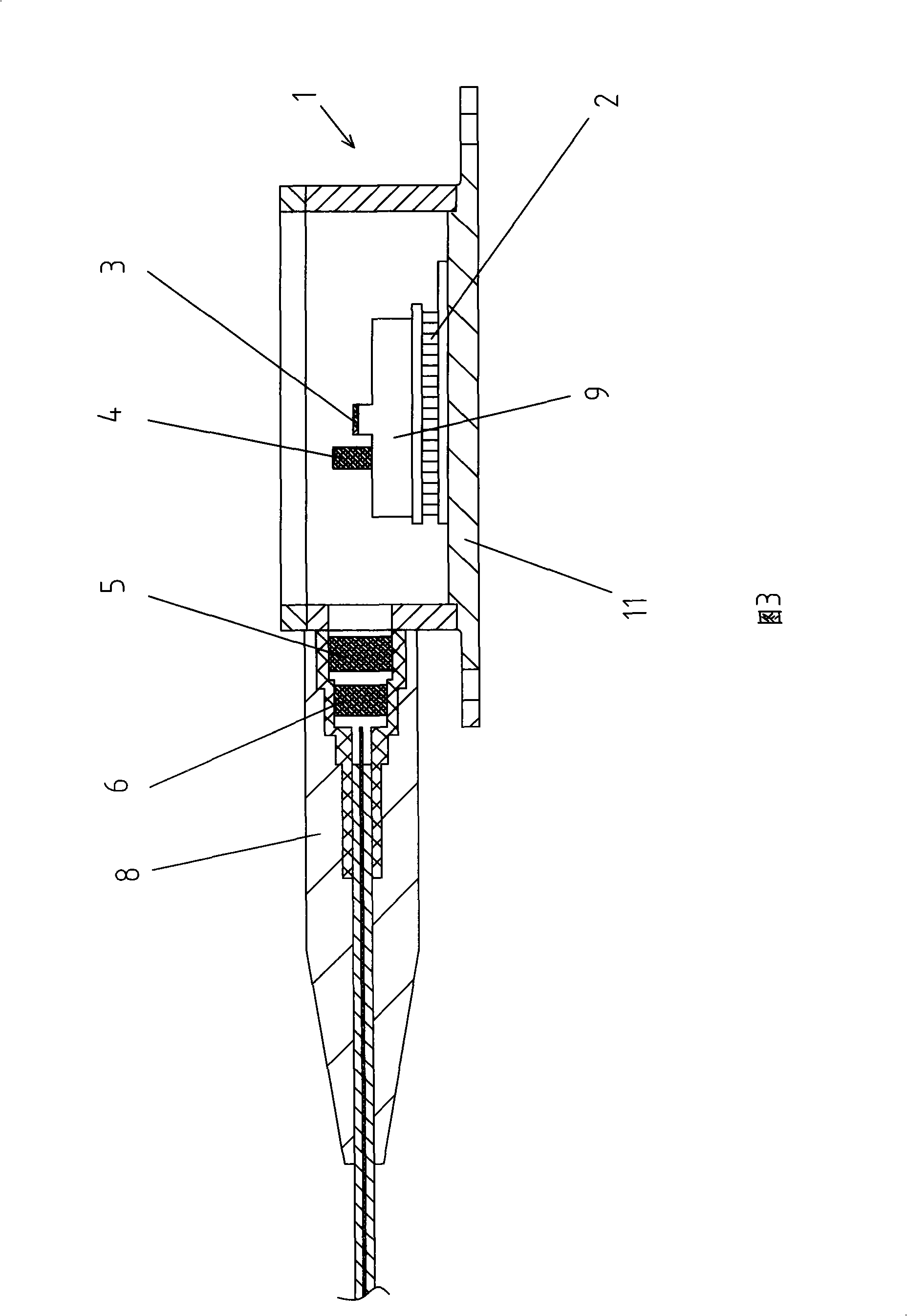

[0015] As shown in Figure 1: 1 is the shell, the shell bottom 11 of the shell 1 is made of tungsten copper material, and the other parts are made of Kovar material. A semiconductor refrigerator (TEC) 2 is provided inside the housing 1 , a first base 9 is provided above the semiconductor refrigerator 2 , and a second base 10 is directly provided on the bottom 11 of the housing. The laser diode (LD) 3 and the first lens 4 are arranged on the first base 9, and the optical isolator 5, the second lens 6, and the optical fiber 7 can be respectively arranged on the 9 and 10 according to the actual situation. The general structure is that a laser diode (LD) 3, a first lens 4 and an optical isolator 5 are arranged on a first base 9, and a second lens 6 and an optical fiber 7 are arranged on a second base 10 (as shown in FIG. 1 ). The end of the optical fiber 7 is fixed by a saddle-shaped optical fiber holder 12 . 8 is a window tube connected with the housing 1, and the inner center l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com