Defatted superfine fresh bone meal and uses thereof

A fresh bone meal, finely pulverized technology, applied in application, food preparation, food science and other directions, can solve the problems of wasting energy, high processing cost, increased processing cost, etc., and achieves simple operation process, high operation reliability, and reduced processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Defatted superfine fresh beef bone powder

[0027] Among all the animal bones, the hardness and strength of the beef rod bone are the largest, the fat content is also high, and the crushing process is difficult. The technical problem of the crushing of the beef rod bone can be solved, and other animal bones can be easily solved.

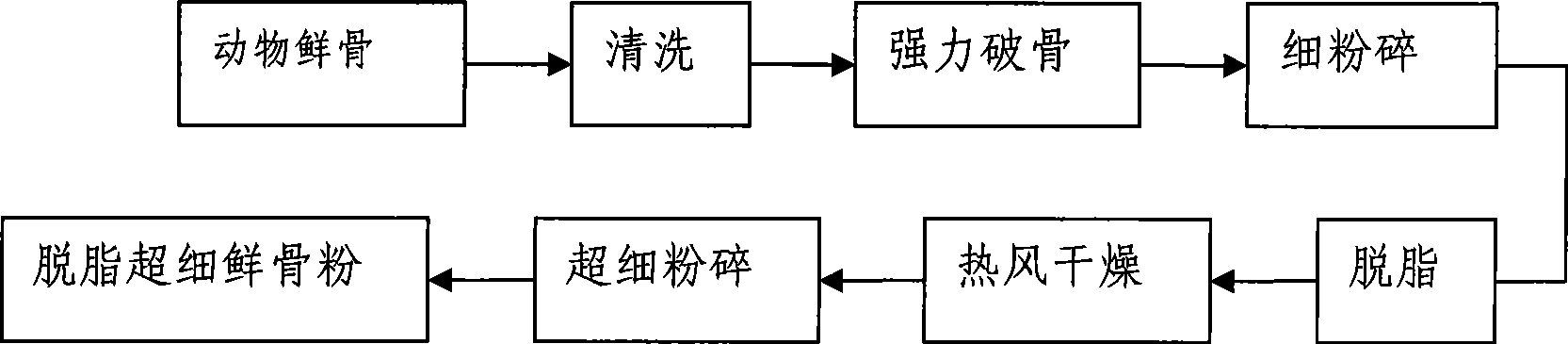

[0028] Such as figure 1 Shown, the degreasing superfine fresh beef bone powder of the present embodiment is made by following method:

[0029] (1) Clean beef stick bones

[0030] Fresh beef stick bones are used as raw materials and washed with water to ensure that the raw material bones meet hygienic requirements.

[0031] (2) Powerful bone breaking

[0032] Put the cleaned raw materials into the powerful bone breaker one by one for strong bone breaking. In order to ensure the smooth discharge of the fresh bone, an appropriate amount of ice water is added when pulverizing, and the amount of ice water added is 30% of the weight of...

Embodiment 2

[0052] Example 2 Defatted ultra-fine fresh pork bone powder

[0053] Such as figure 1 Shown, the degreasing superfine fresh pig bone powder of the present embodiment is made by following method:

[0054] (1) Wash the fresh pork bone

[0055] Fresh pork stick bones are used as raw materials and washed with water to ensure that the raw bones meet the hygienic requirements.

[0056] (2) Powerful bone breaking

[0057] Put the cleaned raw materials into the powerful bone breaker one by one for strong bone breaking. In order to ensure the smooth discharge of the fresh bone, an appropriate amount of ice water is added when pulverizing, and the amount of ice water added is 40% of the weight of the fresh bone. The particle size after coarse crushing is ≤1mm.

[0058] (3) Fine crushing

[0059] The fine crushing of fresh bone adopts bone mud mill. In order to achieve the ideal crushing effect, the material after the strong bone crushing in step (2) is ground twice, and the finer pa...

Embodiment 3

[0068] Example 3 Defatted superfine fresh pork scapula powder

[0069] Such as figure 1 Shown, the degreased superfine fresh pork scapula powder of present embodiment is made by following method:

[0070] (1) Wash the fresh pork shoulder blade

[0071] Fresh pork scapula is used as raw material and washed with water to ensure that the raw material bones meet the hygienic requirements.

[0072] (2) Powerful bone breaking

[0073] Put the cleaned raw materials into the powerful bone breaker one by one for strong bone breaking. In order to ensure the smooth discharge of the fresh bone, an appropriate amount of ice water is added when crushing, and the amount of ice water added is 35% of the weight of the fresh bone. The particle size after coarse crushing is ≤1mm.

[0074] (3) Fine crushing

[0075] The fine crushing of fresh bone adopts bone mud mill. In order to achieve the ideal crushing effect, the material after the strong bone crushing in step (2) is ground twice, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com