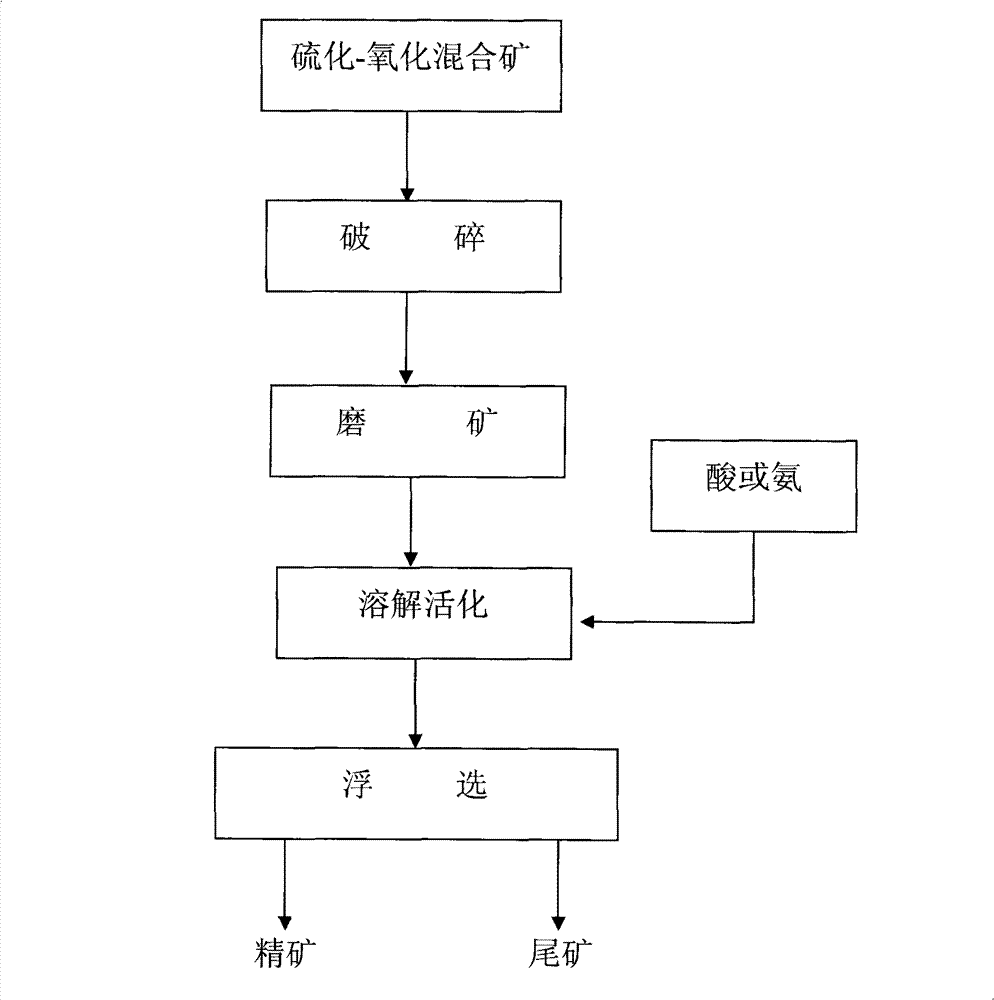

Active flotation method for refractory sulfide mineral in oxidized-sulfide mixed ore

A technology of mixing ore and minerals, applied in flotation, solid separation, etc., can solve the problems of unselectable, low flotation recovery rate and poor effect of sulfide minerals, and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw ore composition: Zn 9.25%, Pb 1.87%, Fe 6.58%, CaO 1.35%, MgO 0.55%, SiO 2 33.71%, zinc oxidation rate 26.78%, lead oxidation rate 18.53%, belonging to lead-zinc mixed ore.

[0024] Above-mentioned raw ore is passed through following processing steps:

[0025] (1) Wet grinding the raw ore to a pulp with a fineness of less than 74 μm, accounting for 84.95%;

[0026] (2) adding sulfuric acid with a concentration of 4.5% to pH=2.5 in the pulp of the above (1) step, stirring and dissolving for 12 minutes;

[0027] (3) Add sodium sulfide in the amount of 245g / t raw ore to the slurry in the above (2) step, and add milk of lime to adjust slurry to slurry pH=9.5;

[0028] (4) Adopt the flow process that prior art is carried out flotation to lead-zinc mixed ore, after the ore pulp of above-mentioned (3) step is carried out flotation, get concentrated ore, wherein, the total dosage of medicament is: mixed collector isobutyl yellow The medicine is added in the amount of 30...

Embodiment 2

[0031] Raw ore composition: Cu 1.05%, CaO 21.84%, MgO 17.46%, SiO 2 8.72%, Fe 4.19%, copper oxidation rate 25.56%, binding rate 7.67%, belonging to high calcium and magnesium mixed copper ore.

[0032] Above-mentioned raw ore is passed through following processing steps:

[0033] (1) Wet grinding the raw ore to a pulp with a fineness of less than 74 μm, accounting for 90.23%;

[0034] (2) Add ammoniacal liquor and ammonium bicarbonate to the pulp total ammonia concentration 1.5mol / L in the pulp of above-mentioned (1) step, wherein the molar concentration ratio of ammoniacal liquor and ammonium bicarbonate is 2: 1, stirring and dissolving for 20 minutes;

[0035] (3) Add sodium hydrosulfide in the amount of 420g / t raw ore in the slurry of the above-mentioned (2) step, and add lime to adjust slurry to slurry pH=9.5;

[0036] (4) After the ore pulp of above-mentioned (3) step is carried out to flotation by adopting the stage grinding concentrated flotation flow process of prio...

Embodiment 3

[0039] Raw ore composition: Cu 1.14%, SiO 2 36.49%, CaO 6.43%, MgO 2.68%, Al 2 o 3 18.57%, Fe 3.54%, copper oxidation rate 15.78%, belonging to high silicon mixed copper ore.

[0040] Above-mentioned raw ore is passed through following processing steps:

[0041] (1) Wet grinding the raw ore to a pulp with a fineness of less than 74 μm, accounting for 88.56%;

[0042] (2) adding sulfuric acid with a concentration of 3.5% to pH=2.9 to the pulp in the above (1) step, stirring and dissolving for 10 minutes;

[0043] (3) Add calcium sulfide in the amount of 220g / t raw ore to the slurry in the above (2) step, and add lime milk to adjust the slurry to pH=9.8;

[0044] (4) After the ore slurry of (3) step is carried out to flotation by adopting the stage grinding and stage flotation processes of the prior art, concentrate ore is obtained, wherein the total dosage of medicament is: collector isobutyl xanthate by 445g / t The amount of raw ore is added, the adjusting agent sodium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com