Diesel motor aluminium alloy cylinder metal mould low-pressure casting method

A technology of diesel engine and low pressure casting, which is applied in the field of metal mold low pressure casting for casting aluminum alloy cylinder blocks of diesel engines, can solve the problems that mechanical properties cannot meet the design requirements, the combination of cylinder liner is not compact, and the waste sand is generated too much. Process yield, simple manufacturing operation, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

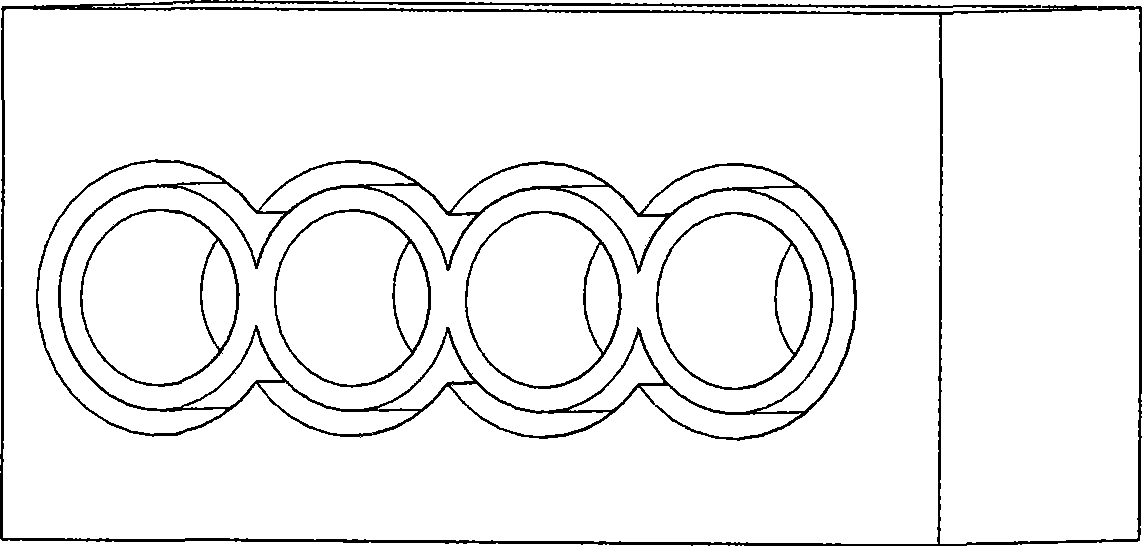

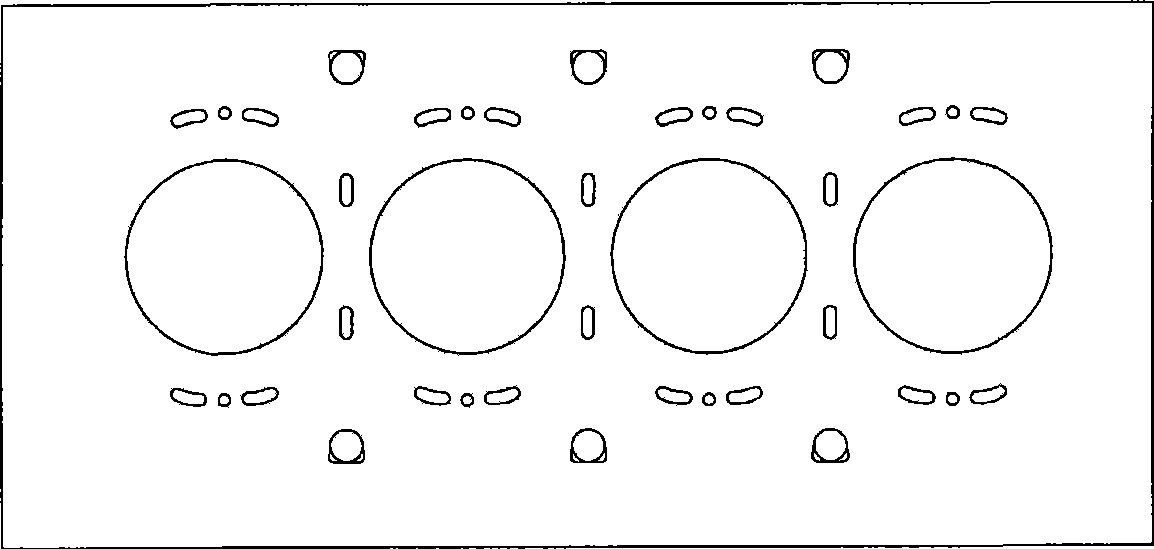

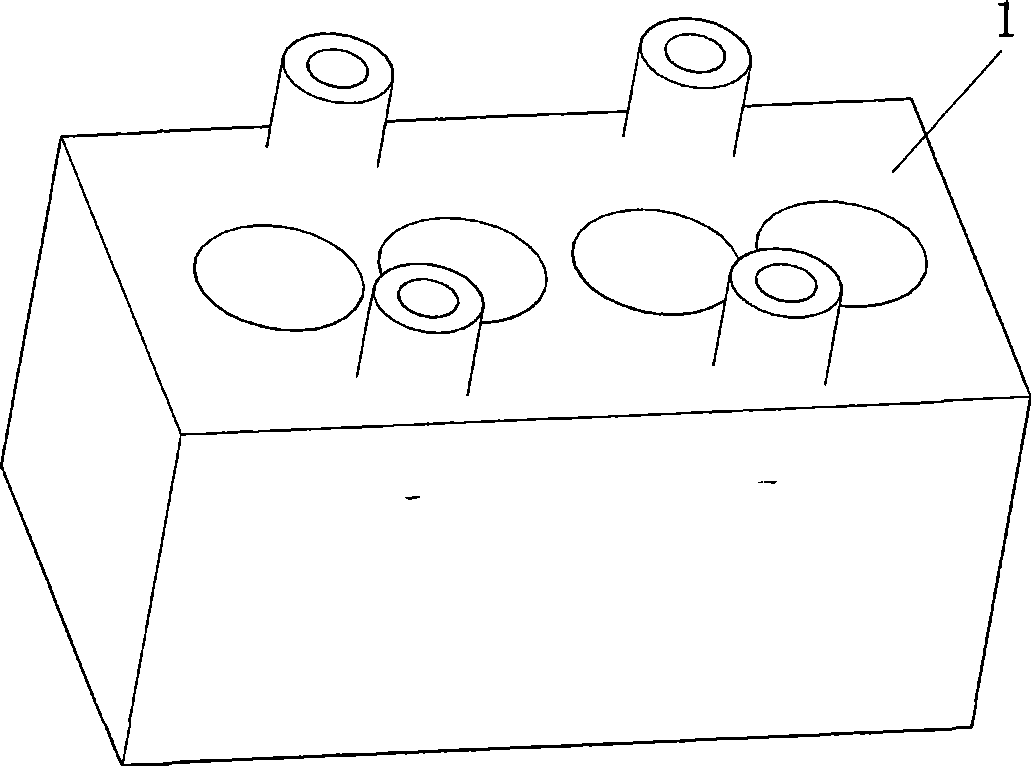

[0034] The metal mold low-pressure casting method for an aluminum alloy cylinder block of a diesel engine disclosed by the invention adopts a metal casting mold and a low-pressure all-metal mold casting method for casting, and includes the steps of low-pressure casting, vibrating sand, rough machining and heat treatment,

[0035] see Figures 3 to 11 , in the low-pressure casting step, the water jacket and the oil passage are respectively cast with the oil passage sand core 11 and the water jacket sand core, and the cylinder liner is cast in an inlaid manner; the entire casting 1 adopts the cylinder surface on the bottom and the crankshaft surface on the top. First, the aluminum is melted, so that the molten aluminum is deteriorated and degassed, and then the water jacket sand core (not shown in the figure) and the oil channel sand core 11 are produced, see Figure 9 and Figure 10 The oil channel sand core 11 includes a large core head 12 and a sand core 6 formed on the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com