Method for preparing inorganic polymer composite aluminum iron zinc coagulant from aluminum plating zincilate

A technology of composite aluminum-iron and coagulant, which is applied in the field of water treatment to achieve excellent coagulation effect, low cost and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

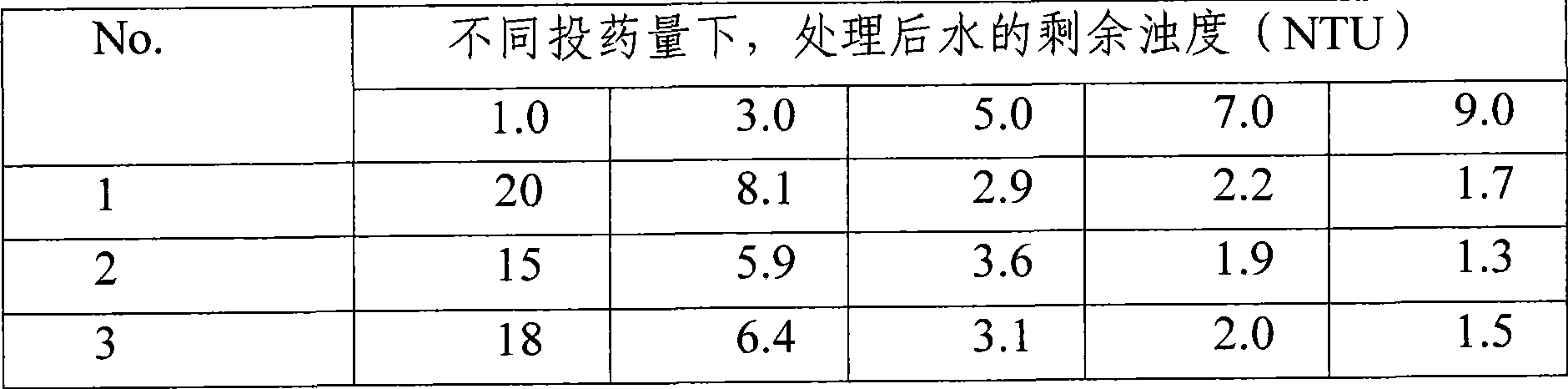

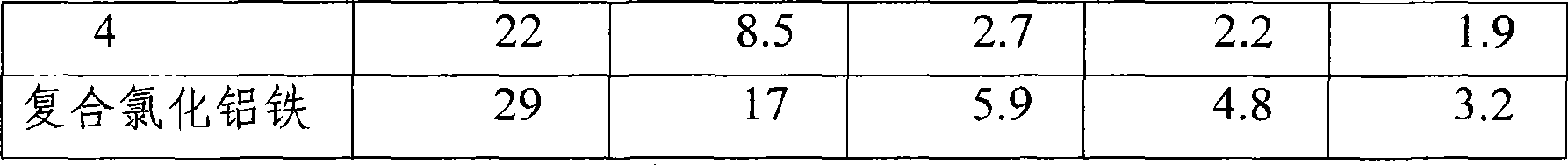

Examples

Embodiment 1

[0019] Break 3kg of galvanized slag into medium or fine slag samples. At a temperature of 70°C to 100°C and stirring conditions of 200 rpm to 600 rpm, add 27.8kg of hydrochloric acid solution (20% by mass fraction) and 2.3kg of sulfuric acid solution (40% by mass fraction) Leach into the above block sample, control the leaching time to 3h, and then filter at a temperature of 40°C to 100°C to obtain a filtrate for future use. Under the temperature condition of 20° C. to 60° C., 62.5 kg of sodium hydroxide (40% by mass) solution was added to the above filtrate, the pH value was controlled to 2.8, and the polymerization was carried out for 3 hours to obtain a milky white liquid product.

Embodiment 2

[0021] Break 3kg of galvanized slag into medium or fine slag samples. At a temperature of 70°C to 100°C and stirring conditions of 200 rpm to 600 rpm, 14.2kg of hydrochloric acid solution (10% by mass fraction) and 2.1kg of sulfuric acid solution (20% by mass fraction) were added Leach into the above block sample, control the leaching time to 15h, and then filter at a temperature of 40°C to 100°C to obtain a filtrate for future use. Under the temperature condition of 20° C. to 60° C., 41 kg of sodium hydroxide (20% by mass) solution was added to the above filtrate, the pH value was controlled to 1.5, and the polymerization was carried out for 3 hours to obtain a colorless liquid product.

Embodiment 3

[0023] Break 3kg of galvanized slag into medium or fine slag samples. At a temperature of 70°C to 100°C and stirring conditions of 200 rpm to 600 rpm, add 10.6kg of hydrochloric acid solution (20% by mass fraction) and 1.4kg of sulfuric acid solution (70% by mass fraction) Leach into the above block sample, control the leaching time to 7h, and then filter at a temperature of 40°C to 100°C to obtain the filtrate, which is set aside. Under the temperature condition of 20° C. to 60° C., 30.8 kg of sodium hydroxide (20% by mass) solution was added to the above filtrate, the pH value was controlled to 2.0, and the polymerization was carried out for 3 hours to obtain a colorless liquid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com