Amination modified vulcanized rubber powder and uses thereof

A technology of vulcanized rubber powder and vulcanized rubber powder, which is applied in the field of vulcanized rubber powder, can solve problems such as complicated process and high difficulty, and achieve the effect of simple modification operation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

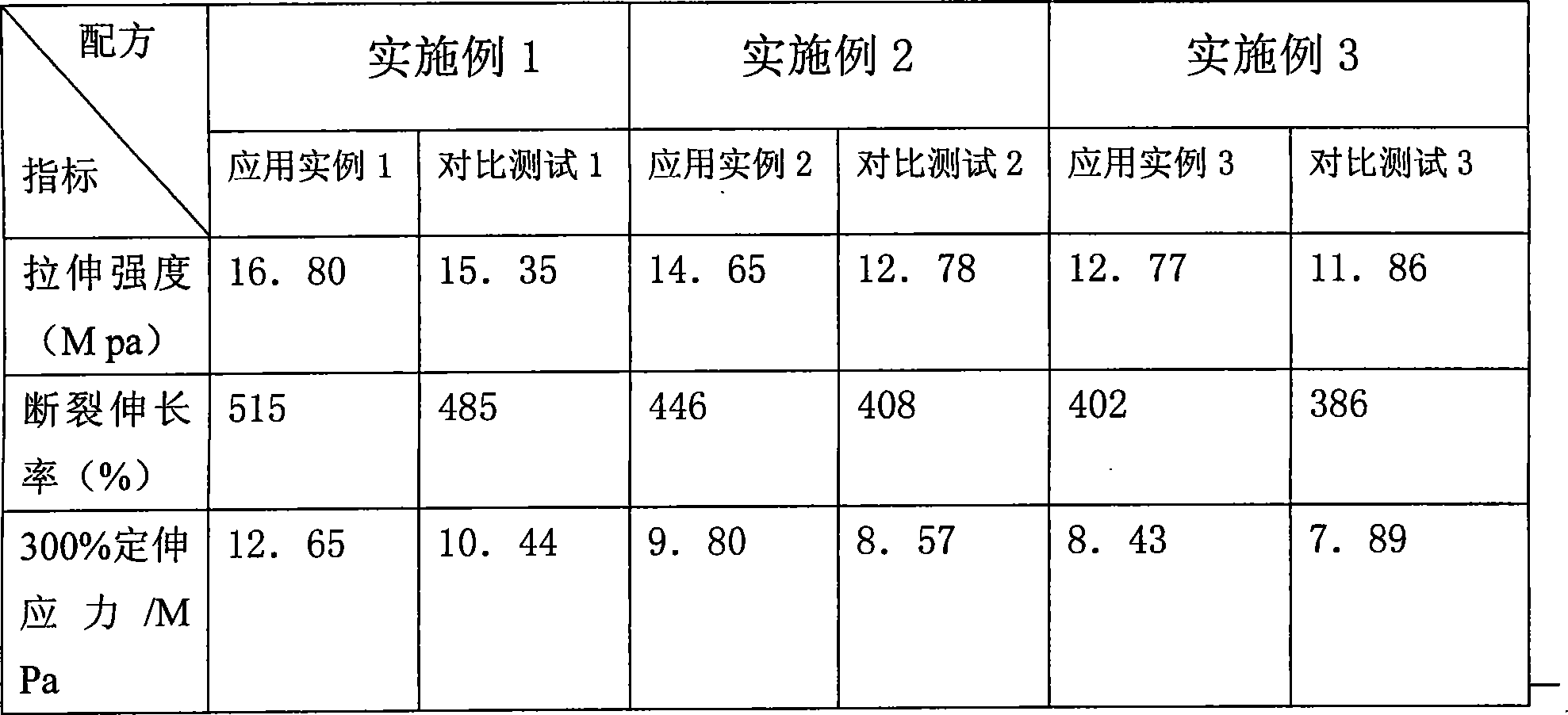

Examples

Embodiment 1

[0028] (1) Graft modification of waste vulcanized rubber powder

[0029] In the reactor, add 500g of waste rubber powder (≤100μm), 1000g of deionized water, start stirring, heat to about 40°C and start adding allylamine solution, ammonium persulfate solution and ferrous sulfate solution dropwise. Among them, 0.75g of ammonium persulfate and 0.5g of ferrous sulfate were added dropwise after making a solution with 15g of water respectively, and 12.5g of allylamine was made into a solution with 25g of water and then added dropwise. The dropping process of monomer and initiator is 1.5h. Then keep the reaction at 40° C. for 0.5 h, lower the temperature, and end the reaction. After filtering and drying, the vulcanized rubber powder modified by surface amination is obtained.

Embodiment 2

[0052] (1) Graft modification of waste vulcanized rubber powder

[0053] In the reaction bottle, add 500g of waste rubber powder (≤100μm), 1000g of deionized water, start stirring, and start to add N-aminoethylacrylamide solution and ammonium persulfate solution dropwise when heated to about 90°C, of which ammonium persulfate is 7.5 g, make a solution with 50g of water and add it dropwise, N-aminoethylacrylamide 50g, make a solution with 50g of water and then add it dropwise. The dropping process of monomer and initiator is 2h. Then keep the temperature at 90° C. for 2 h, cool down, and end the reaction. After filtering and drying, the vulcanized rubber powder modified by surface amination is obtained.

Embodiment 3

[0076] (1) Graft modification of waste vulcanized rubber powder

[0077] In the reactor, add 500g of waste rubber powder (≤100μm) and 1000g of deionized water, start stirring, heat to about 80°C and start adding allylamine solution and ammonium persulfate solution dropwise. Among them, 25g of allylamine was made into a solution with 25g of water and added dropwise; 4g of potassium persulfate was made into a solution of 20g of water and then added dropwise. The dropping process of monomer and initiator is 2h. Then keep the reaction at 90° C. for 1 h, cool down, and end the reaction. After filtering and drying, the vulcanized rubber powder modified by surface amination is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com